4. Engine Performance Issues A noticeable drop in performance, such as a lack of acceleration or engine misfires, can be linked to timing belt problems.

- Proper Tensioning Ensure the belt is correctly tensioned, as both over-tightening and slackness can lead to premature wear or failure.

In summary, the single needle edge cutter machine stands out as an essential tool in the textile manufacturing process. Its ability to deliver precise cuts with efficiency significantly contributes to the overall quality of textile products. As the industry continues to evolve, the role of such machines becomes increasingly important, ensuring that manufacturers can meet consumer demands while adhering to high standards of craftsmanship and sustainability. Investment in advanced equipment like the single needle edge cutter machine not only enhances production capabilities but also helps businesses maintain a competitive edge in the dynamic world of textiles.

Sewing is a rewarding skill that allows you to create beautiful garments, home décor, and other handmade items. Whether you're looking to mend an old piece of clothing or create something new, understanding the basic sewing instructions is essential. This guide will introduce you to the fundamental techniques that every beginner should know.

Climbing ropes are primarily made from synthetic fibers like nylon or polyester. These materials provide the necessary strength and elasticity to manage the immense loads and potential impacts climbers may face. However, constructing these ropes is only part of the process. A crucial step in rope manufacturing involves the sewing of various components, such as rope ends, protective sleeves, and other attachments that enhance usability and safety.

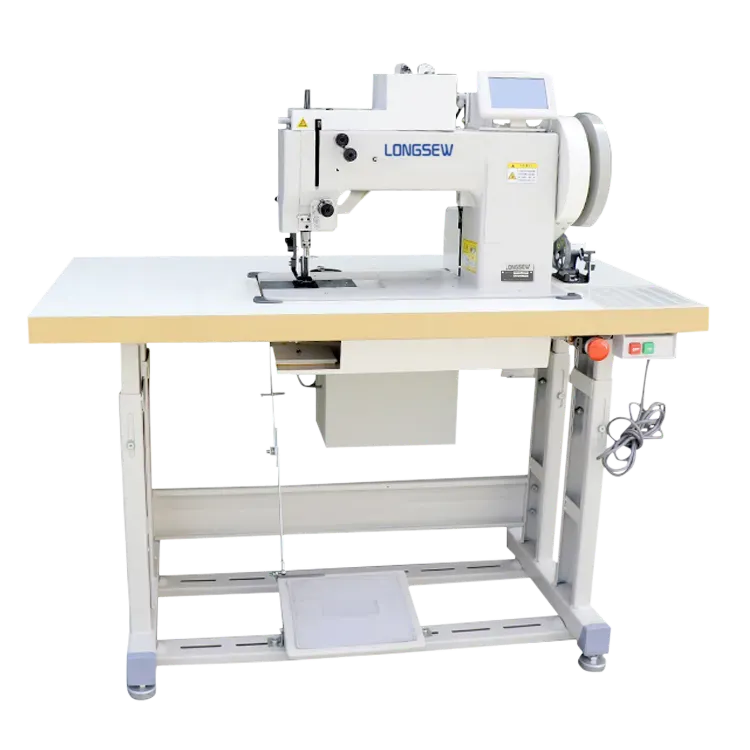

The double needle lockstitch machine is a cornerstone of modern textile manufacturing, renowned for its efficiency, durability, and versatility. As industries continue to evolve, the importance of such machines remains critical in producing high-quality products that meet consumer demands. Whether in a large-scale factory or a small tailor shop, the double needle lockstitch machine proves to be an indispensable tool for fashioning the future of textiles.

3. Cutting Tools Sharp scissors or a rotary cutter will make cutting through heavy canvas cleaner and easier. A cutting mat can also protect your surfaces while allowing precise cuts.

Choosing the Right Sewing Machine

In the world of sewing, single needle sewing machines stand out for their versatility, ease of use, and ability to handle a variety of fabrics. As a fundamental tool in both home sewing and the garment industry, the price of single needle sewing machines varies significantly based on a multitude of factors. Understanding these factors can help potential buyers make informed purchasing decisions.

Conclusion

Proper maintenance is essential for the longevity of any sewing machine, including walking foot models. Regular cleaning to remove lint, oiling the machine as recommended, and ensuring the walking foot is calibrated correctly can help maintain optimal performance. Additionally, investing in quality needles and thread designed for the specific fabric type can enhance the sewing experience and results.

The machine comes equipped with a variety of stitch options, including straight, zigzag, and decorative stitches, giving users the flexibility to create unique designs. Additionally, its adjustable presser foot and feed mechanism ensure that materials are fed smoothly, preventing slipping and allowing for precise sewing. These features combine to offer a comprehensive solution that meets the diverse needs of leather artisans.

Sewing machines come in a range of types designed for different applications and abilities. One of the main categories is heavy duty versus standard sewing machines. Heavy duty sewing machines are made for intensive, high-volume, and heavy fabric sewing, while standard machines are more for basic home and garment construction on lighter fabrics. There are some key differences that set heavy duty and standard machines apart.

Key Features of Industrial Zig Zag Embroidery Machines

Characteristics of Heavy Duty Sewing Machine Motors

3. Walking Foot For projects involving multiple layers of thick fabric, a walking foot (or presser foot) can be invaluable. This feature helps ensure that all layers feed evenly through the machine, preventing uneven stitches and fabric shifting.

stitching automatic machine. These machines can be programmed to perform a wide range of stitching techniques, from basic straight stitches to more complex patterns. This flexibility allows manufacturers to produce a variety of garments, from simple t-shirts to elaborate dresses, without the need for multiple machines.

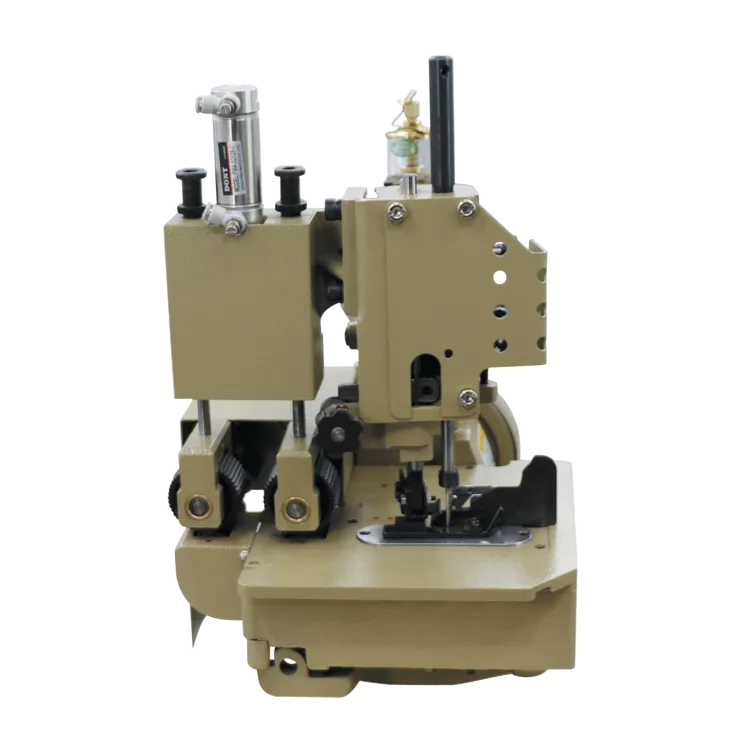

stitching automatic machine. These machines can be programmed to perform a wide range of stitching techniques, from basic straight stitches to more complex patterns. This flexibility allows manufacturers to produce a variety of garments, from simple t-shirts to elaborate dresses, without the need for multiple machines.In recent years, there has been a growing focus on sustainability within the packaging industry. PP bags are recyclable, which aligns with environmental initiatives aimed at reducing plastic waste. As a result, the integration of PP bag stitching machines into production lines also contributes to eco-friendly practices by facilitating the use of recyclable materials.

The only time you REALLY need an industrial sewing machine for me would be if I wanted to sew a lot of stiff layers - those industrial machines are workhorses! Industrial heavy-duty sewing machines differ from heavy-duty home sewing machines in several ways: in speed, power, and durability, and they have specialized components designed for heavy use.

In recent years, the textile industry has witnessed an incredible transformation, largely driven by the advent of technology. Among the standout innovations in this sector is the automatic template sewing machine. This machine has not only streamlined the sewing process but has also significantly enhanced accuracy and productivity, making it a game-changer for both professionals and hobbyists.

Heavy-duty mechanical sewing machines are highly versatile and can be used across many sewing applications. From making durable workwear and outdoor gear to crafting home décor items like curtains and cushions, these machines excel in various projects. For entrepreneurs in the fashion industry, such a machine can facilitate the production of specialized garments designed for rugged conditions, thereby expanding their product lines and catering to niche markets.