...

2025-08-14 08:17

1758

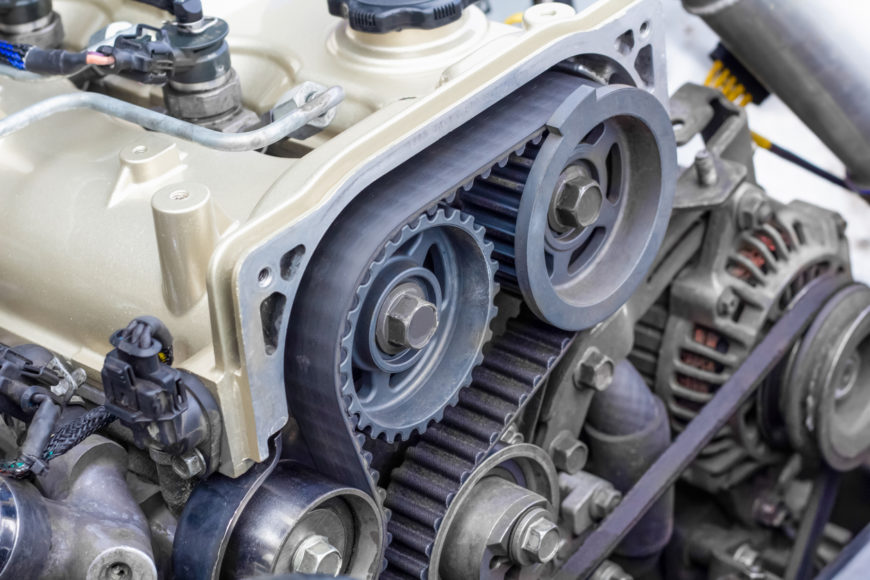

When purchasing drive belts, it's important not to overlook installation costs. Some belts are easier to replace and can be a DIY task for someone with mechanical knowledge, saving labor costs. However, certain types, like timing belts, require specialized tools and expertise, resulting in higher labor costs at a professional shop. Understanding the total cost of ownership, including installation, can help you budget appropriately.

...

2025-08-14 08:11

908

...

2025-08-14 08:09

1818

...

2025-08-14 07:51

289

...

2025-08-14 07:42

446

...

2025-08-14 07:31

2958

...

2025-08-14 07:17

1300

...

2025-08-14 06:50

2802

...

2025-08-14 06:40

1328

...

2025-08-14 06:31

1990

Full Synthetic Motor Oil

- The axia spark plug is a high-performance spark plug that is designed to provide a more efficient and reliable spark for the engine. It is made with a durable construction that can withstand high temperatures and pressures within the engine. The axia spark plug also has a unique design that allows for better fuel combustion and engine performance.

- decreased at low temperature.Vi. Fluoro silicone rubberFluorosilicone rubber, like silica gel, combinesdegrees Celsius), oil resistance (various fuel oil, hydraulic oil, lubricating oil, synthetic oil), solvent

Rubber type

- 2. HVAC Systems In HVAC systems, molded gaskets are used to seal ductwork, air handlers, and other components to prevent air leaks and maintain optimal indoor air quality.

Once you have selected the most suitable seal available, considering the environment, temperature, shaft speed, pressure, lubrication availability, as well as the size, of course, the seal should be stored adequately and then fitted properly. Here are a few suggestions that could help:-

- The primary function of a skeleton oil seal is to maintain the lubrication of machinery by keeping the oil inside and ensuring that it does not leak out. This is essential for the proper functioning and longevity of equipment, as lack of lubrication can lead to increased friction, wear and tear, and ultimately, machine failure.

- When selecting a replacement wheel hub oil seal, it is important to choose one that is specifically designed for your vehicle make and model. This ensures a proper fit and compatibility with the existing components, ensuring optimal performance and reliability.

- The maintenance of oil seals is also crucial to ensure their longevity and effectiveness. Regular inspections should be performed to check for signs of wear, damage, or contamination. If any issues are detected, the seal should be replaced immediately to prevent further damage to the machinery.

B

With the right tools and knowledge, anyone can perform this repair themselves, saving time and money With the right tools and knowledge, anyone can perform this repair themselves, saving time and money

With the right tools and knowledge, anyone can perform this repair themselves, saving time and money With the right tools and knowledge, anyone can perform this repair themselves, saving time and money