Rolls are 25mm Wide.

The Importance of Fire-Resistant Electrical Tape

In airports and logistic centers, it guides forklift operators and personnel, streamlining operations and enhancing efficiency In airports and logistic centers, it guides forklift operators and personnel, streamlining operations and enhancing efficiency

In airports and logistic centers, it guides forklift operators and personnel, streamlining operations and enhancing efficiency In airports and logistic centers, it guides forklift operators and personnel, streamlining operations and enhancing efficiency yellow black floor marking tape.

yellow black floor marking tape.Widths range from one-half of an inch (12 millimeters) to 6 inches (144 millimeters), and available colors are:

For applications that require a higher level of water resistance or waterproofing, specialized tapes or additional measures may be necessary. It’s recommended to assess the specific requirements of your application and consider the expected level of water exposure to determine whether polyethylene tape alone provides sufficient water resistance or if additional waterproofing measures are necessary.

Code:XF-FR085 XF-FR100 XF-FR110 XF-FR120 XF -FR130

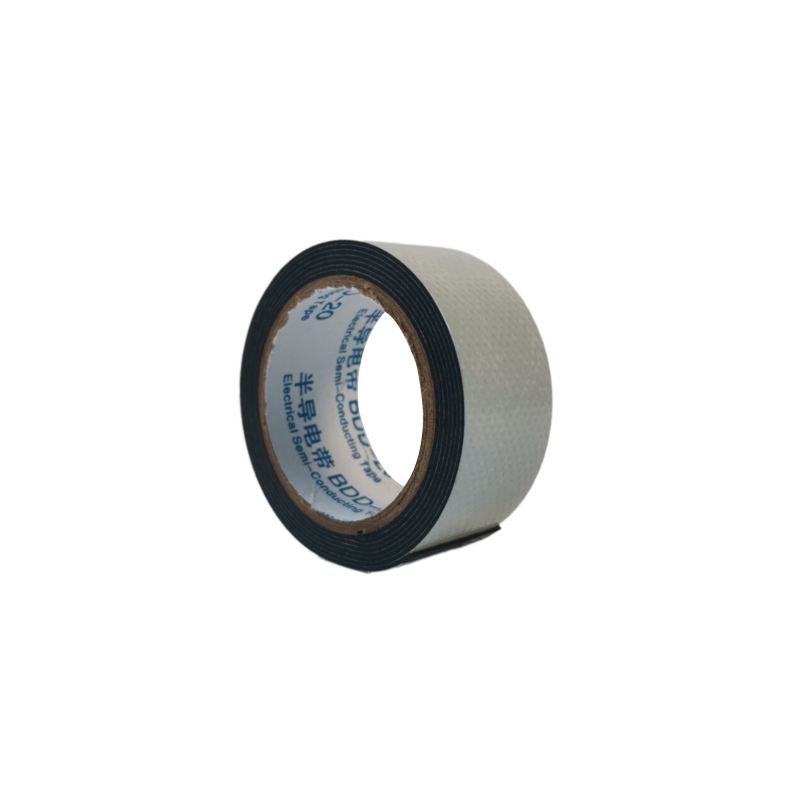

PlB self-amalgamating Tape

In production plants and manufacturing facilities where steam, dripping water and elevated humidity are present, self-fusing rubber tapes provide much needed moisture protection.

Synthetic Elastomers

This means that your roof will maintain its appearance and functionality for many years to come, saving you the expense and hassle of having to replace it prematurely This means that your roof will maintain its appearance and functionality for many years to come, saving you the expense and hassle of having to replace it prematurely

This means that your roof will maintain its appearance and functionality for many years to come, saving you the expense and hassle of having to replace it prematurely This means that your roof will maintain its appearance and functionality for many years to come, saving you the expense and hassle of having to replace it prematurely butyl rubber roofing.

butyl rubber roofing.Inline splice insulation. You can protect a low-voltage inline splice in a similar manner by wrapping the installed connector with four half-lapped layers of rubber mastic tape or rubber splicing tape, and then over-wrapping it with two half-lapped layers of premium vinyl electrical tape.

Conclusion

Anyone who’s left a roll of general purpose vinyl tape in the cab of their truck on a very hot summer day can attest to the fact that heat makes the adhesive soft. Extreme heat makes it ooze and flow.

It can be used to repair damaged insulation on cables or to secure loose connections, providing a temporary or permanent fix It can be used to repair damaged insulation on cables or to secure loose connections, providing a temporary or permanent fix

It can be used to repair damaged insulation on cables or to secure loose connections, providing a temporary or permanent fix It can be used to repair damaged insulation on cables or to secure loose connections, providing a temporary or permanent fix rubber insulation tape. Its adhesive properties ensure a long-lasting bond, while its insulating properties maintain the integrity of the electrical circuit.

rubber insulation tape. Its adhesive properties ensure a long-lasting bond, while its insulating properties maintain the integrity of the electrical circuit.Another important feature of Flex Tape 4 is its strength. The tape is rated to hold up to 50 pounds of weight per square inch, making it suitable for a wide range of applications. Whether you need to repair a leaky pipe, patch up a hole in your roof, or fix a broken garden hose, Flex Tape 4 is up to the task.

flex tape 4

One of the most common uses of heat tape is in plumbing systems. During winter months, exposed pipes are at risk of freezing, which can lead to ruptures and significant water damage. By applying heat tape directly to the pipes, homeowners can ensure that the water remains at a safe temperature, protecting their property from costly repairs.