Environmental considerations are also becoming increasingly relevant in the construction industry. Redispersible latex powders are often formulated to be low in volatile organic compounds (VOCs), making them a more environmentally friendly choice compared to traditional binders. This characteristic aligns with the global push towards sustainable building practices, where eco-friendliness and safety in construction materials are prioritized.

Hydroxypropyl Methylcellulose (HPMC) is a versatile polymer widely used in various industries, particularly in pharmaceuticals, construction, and food. One of the critical aspects of HPMC is its dispersion properties, which significantly impact its functionality in different applications. In this article, we will explore HPMC dispersion, its importance, mechanisms, and applications.

Materials Required

Propyl methyl cellulose (PMC), a derivative of cellulose, has gained significant attention in various industries due to its unique properties and versatile applications. As a non-ionic, water-soluble polymer, PMC plays a crucial role in fields such as food, pharmaceuticals, construction, and personal care products.

Applications of HPMC 200000

5. Easy Processing The powder form of redispersible polymers allows for easier processing and incorporation into various systems. They can be easily blended with other ingredients, reducing the complexity of manufacturing processes.

hpmc types

Advantages of Choosing HPMC from China

3. Viscosity and Texture The ability of HPMC to provide a specific viscosity is heavily dependent on how well it is dispersed in the solvent. This property is vital for applications like adhesives, coatings, and food products.

- Composition/Information on Ingredients HEC is the main ingredient, with specific grades and molecular weights defined for different applications.

Applications in Various Industries

Conclusion

Conclusion

In the realm of cosmetics, HPMC is valued for its thickening and stabilizing characteristics. It is frequently found in lotions, creams, and gels, enhancing the product’s texture and application. HPMC also helps in holding water in formulations, preventing them from becoming dry or flaky over time. This hydrating ability is a crucial factor in personal care products aimed at moisturizing the skin.

China’s Role as a Supplier

Redispersibility: The ability of a powder to redisperse in water is a critical parameter. It is usually tested by dispersing the powder in water and evaluating properties such as viscosity, stability and film-forming properties.

In the food industry, HPMC serves multiple functions, including as a thickening agent, emulsifier, and stabilizer. Its ability to retain moisture makes it invaluable in low-fat and gluten-free products, where it helps mimic the texture typically provided by fats or gluten. HPMC's stabilizing properties help in maintaining the consistency and quality of sauces, dressings, and dairy products, while also enhancing the mouthfeel of beverages. Moreover, as a food additive, HPMC is considered safe and is approved by regulatory authorities, which further widens its acceptance and application in food formulations.

use of hpmc

Another significant advantage of HPMC is its compatibility with a variety of ingredients, including anionic, cationic, and nonionic surfactants. This versatility allows formulators to create unique and effective detergents tailored to specific cleaning applications. For instance, HPMC can enhance the performance of laundry detergents, dishwashing liquids, and all-purpose cleaners. Its ability to improve the solubilization of active ingredients results in better cleaning action, making products more effective while potentially reducing the quantity of active substances required.

hpmc uses in detergent

Construction and Building Materials

Hydroxypropyl Methylcellulose (HPMC) is a non-ionic, water-soluble polymer derived from cellulose. It is widely used in various applications, from pharmaceuticals to food products, and most notably in the construction sector as a thickening agent and binder in tile adhesives and grouts. HPMC is produced through the reaction of cellulose with propylene oxide and methyl chloride, resulting in a versatile compound that enhances the performance of adhesive products.

3. Cosmetic and Personal Care Products HPMC's thickening and film-forming properties make it ideal for use in lotions, creams, and gels. It enhances the feel of products on the skin, improves texture, and provides stability to emulsions. As consumers increasingly seek natural and safe ingredients in cosmetics, HPMC's biocompatibility aligns well with market trends.

5. Agricultural Supply Stores

The Role of Hydroxypropyl Methylcellulose in Supplements

1. Immediate Availability You can inspect the product and sometimes receive it the same day.

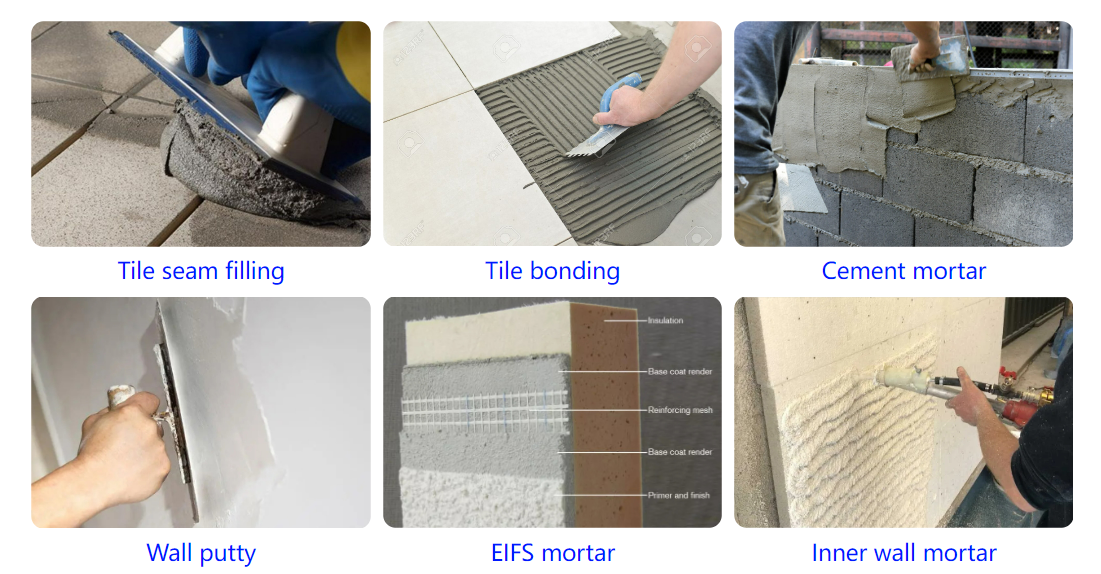

The versatility of RDP extends beyond tile adhesives and plasters. It is also employed in self-leveling compounds, repair mortars, and exterior insulation finishing systems (EIFS). Its ability to adapt to various formulations makes RDP a valuable ingredient in the development of advanced construction solutions. Manufacturers are continuously exploring new applications for RDP, recognizing its potential to innovate and improve existing products.

Looking ahead, the future pricing landscape for hydroxyethyl cellulose is likely to be influenced by various trends. The global push towards sustainability and eco-friendly products is expected to drive demand for HEC, particularly in natural and organic formulations. This trend may lead to increased production efforts and innovations in manufacturing processes, potentially stabilizing prices in the long run.

Cellulose, one of the most abundant organic polymers on Earth, has been a cornerstone of various industries for centuries. Among its derivatives, cellulose ether has gained significant attention due to its unique properties and versatile applications. Cellulose ether is formed by the chemical modification of cellulose, where ether groups are introduced into the cellulose structure. This modification alters both the solubility and the functional characteristics of cellulose, making it a valuable resource across many fields.

As demand for HPMC continues to grow, the role of manufacturers becomes increasingly important. Companies specializing in HPMC production are continually investing in research and development to improve the quality, functionality, and sustainability of their products. Striking a balance between performance and environmental responsibility is a significant focus, with many manufacturers exploring green chemistry techniques and sustainable sourcing of raw materials.

One of the most significant uses of HPMC is in the construction industry, particularly in the preparation of cement-based materials such as tile adhesives, plasters, and paints. HPMC enhances the workability of these materials, providing better adhesion and improving the flow of substances during application. Additionally, it helps to retain water, which is essential for the curing process of cement products. This property ensures that projects not only have longer open times, allowing for easier application, but also achieve optimal setting and ultimate strength.

Exploring China HPMC A Key Player in Modern Industries

Exploring the HPMC Website A Gateway to Quality and Innovation

For industries that require high purity and specific grades of hydroxyethyl cellulose, specialty chemical suppliers are an excellent choice. Companies like Sigma-Aldrich, BASF, and Dow Chemical provide HEC in various formulations suited for different applications. These suppliers often have a wealth of technical knowledge and can offer guidance on the appropriate type of HEC for your project. By purchasing from reputable suppliers, you can ensure that you receive high-quality materials that meet strict industry standards.

HPMC can be categorized based on different parameters, including the degree of substitution, viscosity, and solubility. The primary classifications include

Applications of HPMC in Mortar

Environmental sustainability is increasingly becoming a focal point for consumers and industries alike. Hydroxyethyl cellulose is biodegradable and derived from renewable resources, aligning with the growing trend towards sustainable product development. Dow emphasizes the importance of sustainable practices in its manufacturing processes and is committed to minimizing its environmental footprint while meeting market demands.

3. Open Time Extension HPMC prolongs the open time of tile adhesives, giving installers ample opportunity to adjust tiles during installation without compromising the bond strength. This is especially important for larger tiles or intricate designs.

In conclusion, hydroxyethyl cellulose stands out as a highly versatile and functional polymer that bridges the gap between nature and modern technology. Its wide-ranging applications across various industries underscore its significance in formulating products that meet contemporary demands while maintaining safety and effectiveness. As research continues to explore new possibilities, HEC will likely remain an integral component of innovative formulations for years to come.

Exploring the HPMC Website A Gateway to Health and Nutrition

5. Fire-Fighting Measures An important aspect of the SDS, this section details the fire hazards associated with HPMC and suitable extinguishing media, helping staff to prepare for potential fire-related incidents.

The backbone of HPMC is cellulose, which consists of repeating cellobiose units linked by β-1,4-glycosidic bonds. This linear structure forms a rigid framework, providing mechanical strength and stability. To derive HPMC, cellulose undergoes etherification, where methyl and hydroxypropyl groups are introduced into the cellulose chain. The degree of substitution (DS) of these groups determines the properties and performance of HPMC. Typically, the hydroxypropyl content ranges from 4% to 32%, while the methoxy content can be as high as 30%.

2. Versatility HPMC can be used in various adhesive formulations, including those for ceramic tiles, porcelain tiles, and stone tiles. This versatility makes it a preferred choice among manufacturers aiming to create high-quality products that meet diverse installation needs.

Pharmaceutical Sector Significance

3. Flexibility By adding RDP powder, the flexibility of the mixed material is significantly improved, providing the ability to expand and contract without cracking.

Redispersible Polymer Powder An Overview

The quality of HPMC is paramount to its effectiveness in end-user applications. Manufacturers are often required to adhere to stringent quality control measures and international standards such as ISO and cGMP (Current Good Manufacturing Practices). This ensures the consistency and reliability of HPMC products, which is essential for critical applications in pharmaceuticals and food.

3. Plastering Compounds HPMC is often added to plaster compounds to enhance spreadability and adhesion. It increases the plasticity of the mixture, allowing for smoother application and finishing. This results in a more uniform surface and a significantly improved final appearance, which is crucial in high-quality construction projects.

construction hpmc

Pharmaceutical Applications

In conclusion, the diverse types of HPMC—ranging from low to high viscosity—cater to a myriad of applications across different industries. Understanding these categories facilitates effective selection for specific production requirements, ensuring optimal performance and outcomes. As industries continue to evolve and seek innovative solutions, the relevance of HPMC and its types will remain significant, highlighting the importance of ongoing research and development in this field. Whether for improving the texture of food products, enhancing the potency of pharmaceutical formulations, or boosting the performance of construction materials, HPMC types are an essential part of modern formulation science.