- When it comes to electrical maintenance and repair, having the right tools on hand is crucial. One such tool that is often overlooked but can be incredibly useful is black fabric electrical tape. This versatile tape is made from a high-quality fabric base and coated with an adhesive that is specifically designed to adhere to electrical components and insulation.

- 1. Clean the surface Before installing butyl rubber flashing, ensure that the surface is clean and free of dirt, debris, and. This will help the flashing adhere better to the surface.

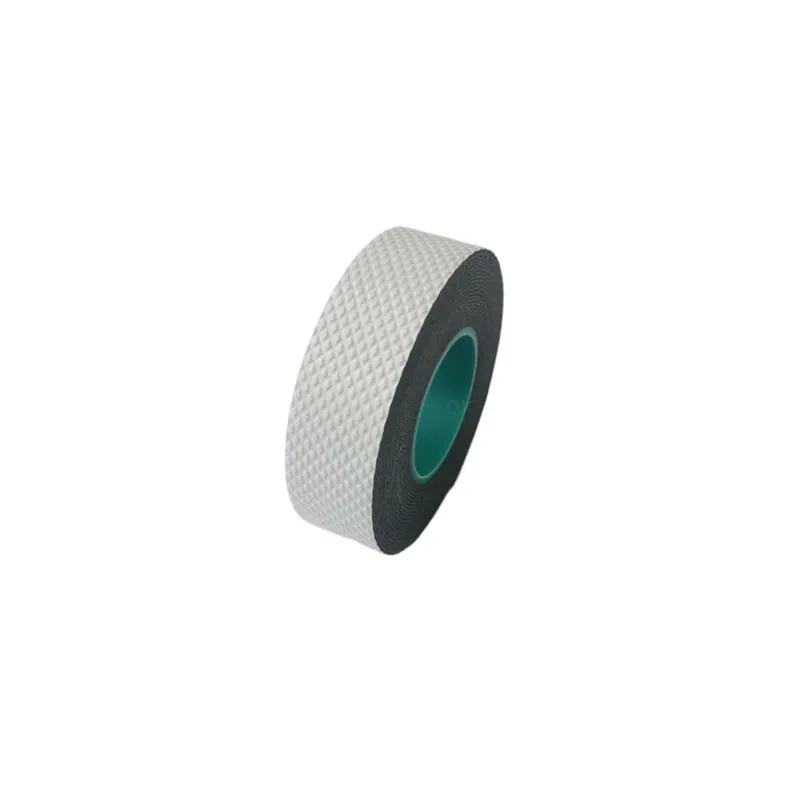

- The primary function of self-adhesive PVC insulation tape is to insulate and protect electrical wires and cables. It safeguards conductors from damage, prevents short circuits, and ensures that electrical currents flow safely along their designated paths. Its conformability allows it to adhere seamlessly to irregular surfaces, making it ideal for wrapping around curved or contoured wire bundles.

A door bottom seal rubber strip is an essential component for insulating and weatherproofing doors. These strips are designed to create a tight seal at the bottom of the door, preventing drafts, dust, insects, and moisture from entering your home. They help to maintain a comfortable indoor temperature, reduce energy costs, and improve overall air quality.

PlB self-amalgamating Tape

At its simplest, a control box is an enclosure that houses electrical components such as switches, knobs, and controls. It’s the central point from which electrical circuits are managed, distributed, and protected. Think of it as the brain of an operation where the electrical nervous system can be coordinated with precision. In industrial applications, control boxes oversee the process of heavy machinery. In a residential context, they might regulate heating and cooling systems. The primary functions of a control box include:

In addition to its ease of use, self-adhesive electrical tape is also highly durable

. It can withstand high temperatures, making it suitable for use in a variety of environments. Whether you are working in a hot attic or a cold basement, this tape will hold up under extreme conditions.self adhesive electrical tape

In 1845, a surgeon named Dr. Horace Day made the first crude surgical tape by combining India rubber, pine gum, turpentine, litharge (a yellow lead oxide), and turpentine extract of cayenne pepper and applying that mixture to strips of fabric. It was the first “rubber-based” adhesive and Dr. Day used it in his practice as a surgical plaster. Larger scale manufacturing of similar medical tapes began in 1874 by Robert Wood Johnson and George Seaburg in East Orange, NJ. That company would soon become the Johnson & Johnson Company we know today. Later in 1921, Earle Dickson who bought cotton for Johnson & Johnson noticed that the surgical tape kept falling off his wife Josephine’s fingers after cutting them in the kitchen. He fixed a piece of gauze to some cloth backed tape and the first Band-Aid ® was invented. It took almost 75 years from Dr. Day’s first crude tape until the early 1920’s when the first industrial tape application appeared. The application was electrical tape (although the adhesive was more of a cohesive film than the electrical tape we know today) to prevent wires from shorting. The second major industrial tape application was a result of the rise of the American automobile in the 1920’s. Two-toned automobiles were becoming popular and automakers needed a way to produce clean, sharp paint lines while using the new automatic paint spray gun. They started using the surgical tape that was available but the paint wicked through the cloth backing and caused defective paint jobs. Richard Drew, an engineer at Minnesota Mining and Manufacturing (3M) happened to be at a local body shop testing their WetorDry® brand sandpaper in 1925 and he saw the workers struggling to get clean paint lines. He went back to his lab and created a 2-inch wide crimp backed paper tape that became the first “masking tape” for painting. Jumping ahead to 1942 and World War II, Johnson & Johnson developed duct tape to seal canisters and repair equipment for the military. The tape was a basically a polyethylene coated cloth tape with good “quick stick” properties that made it easy to use in the field for emergency repairs. The world never looked back and duct tape can be found in almost any home or toolbox.

The Versatile Utility of Yellow Tape Electrical

It can be easily wrapped around electrical components, joints, and connections to provide a secure and reliable insulation barrier It can be easily wrapped around electrical components, joints, and connections to provide a secure and reliable insulation barrier

It can be easily wrapped around electrical components, joints, and connections to provide a secure and reliable insulation barrier It can be easily wrapped around electrical components, joints, and connections to provide a secure and reliable insulation barrier 33kv insulation tape. This not only simplifies the installation process but also minimizes the risk of incorrect applications that could compromise the safety and performance of the electrical system.

33kv insulation tape. This not only simplifies the installation process but also minimizes the risk of incorrect applications that could compromise the safety and performance of the electrical system.Choose for secure online shopping, fast delivery, easy returns, and top-notch customer service. and get support to decide which tape is best for you.

pvc insulation tape. Its waterproof nature makes it suitable for outdoor use, protecting electrical connections from dampness and corrosion. It can also be used for marking and identification purposes, thanks to its writable surface.

pvc insulation tape. Its waterproof nature makes it suitable for outdoor use, protecting electrical connections from dampness and corrosion. It can also be used for marking and identification purposes, thanks to its writable surface.How Does It Work?

Repair Needs: Assess the nature and extent of your repair requirements. Each tape is best suited for different types of repairs.

Weather resistance – in addition to withstanding low temperatures, PVC tape is resistant to harsh weather conditions thanks to its PVC coating. The tough, outer layer will cope well with metal corrosion and bad weather.

3. Durability and Longevity Fireproof gasket tape is engineered to stand the test of time. It is resistant to degradation caused by UV light, moisture, and extreme temperatures, ensuring a long-lasting seal that minimizes the need for frequent replacements. This durability is particularly beneficial in harsh industrial environments, where traditional tapes may fail prematurely.

In addition to safety, fire-resistant electrical tape can increase the longevity of electrical connections. Regular electrical tape may degrade over time, especially under extreme conditions, leading to insulation failures. The durability of fire-resistant tape means it can withstand harsher conditions, thereby extending the lifespan of electrical installations.

It is resistant to tearing, abrasion, and other forms of physical damage, making it ideal for use in harsh industrial environments It is resistant to tearing, abrasion, and other forms of physical damage, making it ideal for use in harsh industrial environments

It is resistant to tearing, abrasion, and other forms of physical damage, making it ideal for use in harsh industrial environments It is resistant to tearing, abrasion, and other forms of physical damage, making it ideal for use in harsh industrial environments insulation tape yellow. It can also be easily trimmed to size using scissors or a utility knife, allowing workers to customize the tape to fit their specific needs.

insulation tape yellow. It can also be easily trimmed to size using scissors or a utility knife, allowing workers to customize the tape to fit their specific needs.Moreover, the ease of application and removal enhances its popularity. It adheres well to surfaces but can be removed without leaving a sticky residue, making it suitable for temporary applications. It is also easy to cut, allowing for customization in width and length according to specific needs.

On the other hand, duct tape is a cloth-backed pressure-sensitive tape made of a thin polyethylene-coated cloth with fibers and a rubber-based adhesive on the other. This composition makes duct tape extremely durable, water-resistant, and great for a wide range of applications.

How Control Boxes Keep Operations Running Smoothly

PVC insulation tape uses

Our buyer’s guide will tell you everything you need to know about this handy tape.

industrial floor marking tape. It requires minimal downtime, making it ideal for busy facilities. The tape can be easily removed without leaving residue, allowing for quick changes or updates when needed.

industrial floor marking tape. It requires minimal downtime, making it ideal for busy facilities. The tape can be easily removed without leaving residue, allowing for quick changes or updates when needed.