These materials ensure the sleeves can withstand the high pressure and harsh environments prevalent in hydraulic systems These materials ensure the sleeves can withstand the high pressure and harsh environments prevalent in hydraulic systems

These materials ensure the sleeves can withstand the high pressure and harsh environments prevalent in hydraulic systems These materials ensure the sleeves can withstand the high pressure and harsh environments prevalent in hydraulic systems coupling sleeve for hydraulic. Some sleeves may also incorporate brass or aluminum for lighter weight applications.

coupling sleeve for hydraulic. Some sleeves may also incorporate brass or aluminum for lighter weight applications.

bit for rock drilling.

Post time: Mar-13-2020

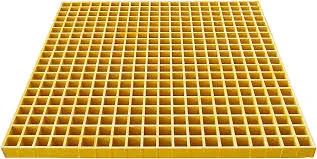

Fiberglass is known for its high strength-to-weight ratio, which makes it an ideal material for applications that require long-term durability Fiberglass is known for its high strength-to-weight ratio, which makes it an ideal material for applications that require long-term durability

Fiberglass is known for its high strength-to-weight ratio, which makes it an ideal material for applications that require long-term durability Fiberglass is known for its high strength-to-weight ratio, which makes it an ideal material for applications that require long-term durability