A steep decline in the prices of titanium dioxide was observed in the second half of 2022 as the erratic energy costs along with rising covid cases affected the market negatively. In addition to this, the decreased offtakes from paints and coating industries, weak economic growth, and strict restrictions imposed to deal with the resurgence of covid cases further aided the declining trajectory of titanium butoxide prices.

Moreover, TiO2's photocatalytic properties can break down organic pollutants under sunlight, making it environmentally friendly and contributing to cleaner air Moreover, TiO2's photocatalytic properties can break down organic pollutants under sunlight, making it environmentally friendly and contributing to cleaner air

Moreover, TiO2's photocatalytic properties can break down organic pollutants under sunlight, making it environmentally friendly and contributing to cleaner air Moreover, TiO2's photocatalytic properties can break down organic pollutants under sunlight, making it environmentally friendly and contributing to cleaner air titanium dioxide in coatings factory.

titanium dioxide in coatings factory.Lithopone 30% has a lower coverage power than titanium dioxide. For this reason, Lithopone 30% can only partially substitute titanium dioxide, between 5 and 40%.

There is some concern regarding skin and intestinal absorption of titanium dioxide nanoparticles, which are less than 100 nm in diameter.

Founded in 1902 by Henrick J. Krebs, Krebs Pigments and Chemical Company produced lithopone, a widely used white paint pigment also manufactured by DuPont. But Krebs' company had another asset of special interest to DuPont. ...

Titanium dioxide is the most widely used whitening pigment in the world and has been linked to adverse health effects, particularly genotoxicity and intestinal inflammation. It is applied as food coloring and a whitening agent to a wide variety of foods, including chewing gum, cakes, candies, breads and ice cream.

Titanium dioxide is used in the production of paper and textiles to improve whiteness, brightness, opacity and durability. It’s often used in fabrics, yarns, paper and other fibers.

It's all over the place in our environment, said Dr. Johnson-Arbor.

Below 10% substitution, 1 kg of TiO2 should be replaced by 1 kg of Lithopone 30%.

Inflammation of the intestines

See also

lithopone 28%-30% pricelist supplier.

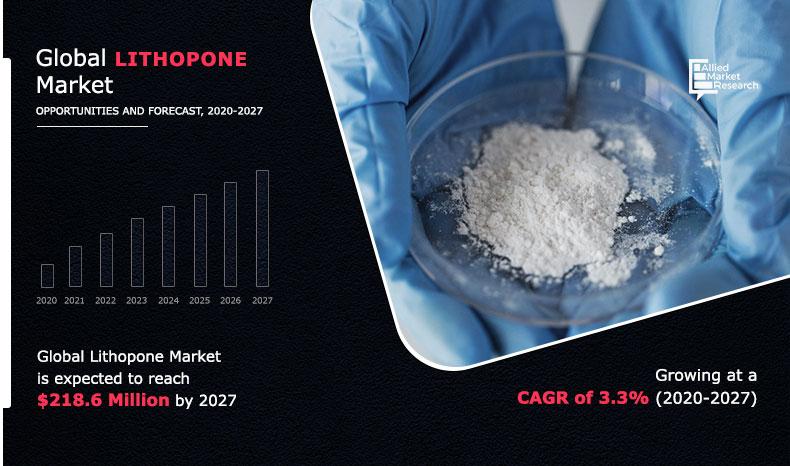

Lithopone, C.I. Pigment White 5, is a mixture of inorganic compounds, widely used as a white pigment powder. It is composed of a mixture of barium sulfate and zinc sulfide. These insoluble compounds blend well with organic compounds and confer opacity. It was made popular by the cheap production costs, greater coverage. Related white pigments include titanium dioxide, zinc oxide (zinc white), zinc sulfide, and white lead.[1]

The endpoint of the titration is determined either by a color change indicator or more sophisticated instrumentation like a potentiometric titrator The endpoint of the titration is determined either by a color change indicator or more sophisticated instrumentation like a potentiometric titrator

The endpoint of the titration is determined either by a color change indicator or more sophisticated instrumentation like a potentiometric titrator The endpoint of the titration is determined either by a color change indicator or more sophisticated instrumentation like a potentiometric titrator determination of sulphate as tio2. The volume of titrant used corresponds to the concentration of sulfate in the sample. Again, a stoichiometric calculation converts this to TiO2 content.

determination of sulphate as tio2. The volume of titrant used corresponds to the concentration of sulfate in the sample. Again, a stoichiometric calculation converts this to TiO2 content.The CaCO3 and TiO2 factory plays a crucial role in producing these materials on a large scale to meet the growing demand from various industries. The factory utilizes advanced technology and processes to extract and refine CaCO3 and TiO2 from natural resources such as limestone and mineral sands. The production process involves crushing, grinding, and chemical treatment to obtain the desired properties of CaCO3 and TiO2.