These belts are designed to operate efficiently, minimizing energy loss during power transmission. This efficiency translates to lower operational costs, making them an economical choice for long-term use.

Essential Features for Leather Jacket Sewing Machines

The CB2500 is equipped with a wide array of features that enhance its functionality and performance. One of its notable characteristics is its multiple stitch options. With an array of built-in stitches, including straight, zigzag, and decorative stitches, users can effortlessly switch between styles to achieve the desired finish for any project. This versatility allows for greater creativity, encouraging users to experiment with different techniques and designs.

In recent years, the world of sewing has evolved significantly, especially with the advent of fully automatic sewing machines. These innovative machines have changed the landscape of sewing, making it easier for both beginners and experienced sewers to create high-quality garments and crafts. As a result, the demand for fully automatic sewing machines has surged, leading to a variety of options in the market, each with differing prices.

A double stitch machine, often referred to as a double needle sewing machine, utilizes two needles working in tandem, allowing it to create two parallel rows of stitching simultaneously. This feature is particularly advantageous for sewing thick materials, as it distributes the tension more evenly across the fabric. The dual needle setup not only saves time but also significantly improves the durability and strength of the seams, critical factors in the longevity of textile products.

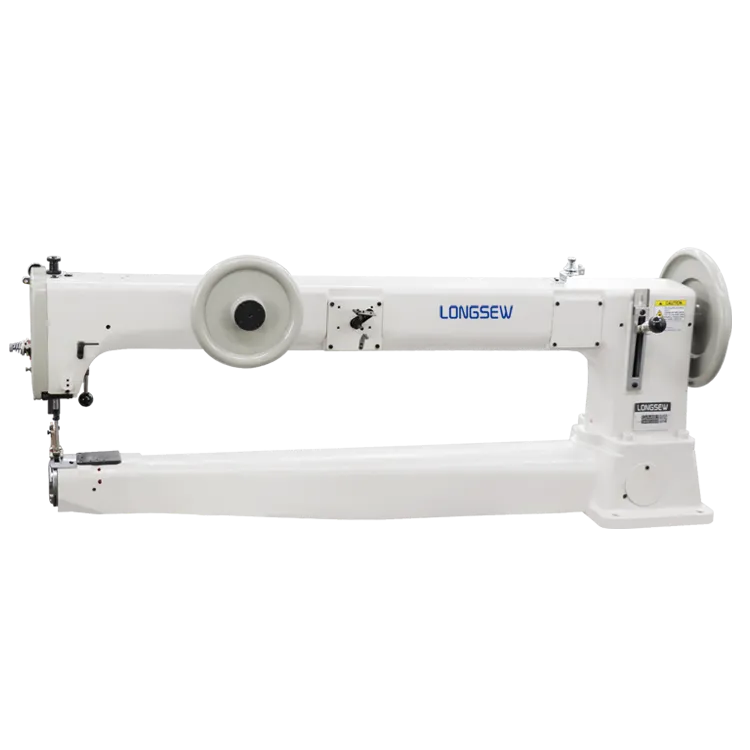

Moreover, industrial leather sewing machines offer speed and efficiency, key factors in a commercial setting. They can sew a long seam in a fraction of the time it would take using a domestic machine, significantly boosting productivity. This is especially beneficial for businesses that require a high output, such as handbag manufacturers, upholstery experts, and leather garment producers.

The industrial chain stitch machine plays a vital role in the textile and garment manufacturing sectors. This machine is designed to create a series of interlocking loops of thread, forming a strong and durable seam. Its unique functionality makes it particularly suitable for various applications, from sewing lightweight fabrics to handling heavy textiles, thus underscoring its versatility and significance in modern manufacturing processes.

- Model and Features Different models come with various features, such as adjustable stitch width and length, automatic tension control, and built-in walking feet for best fabric handling. Evaluate your specific sewing needs to select the right model.

1. Standard Foot This is the most common presser foot, ideal for general sewing tasks. It works well for straight stitching and basic construction, making it suitable for beginners learning to sew.

Choosing the Right Sewing Machine

Factors Influencing the Price

The double needle lockstitch machine is a cornerstone of modern textile manufacturing, renowned for its efficiency, durability, and versatility. As industries continue to evolve, the importance of such machines remains critical in producing high-quality products that meet consumer demands. Whether in a large-scale factory or a small tailor shop, the double needle lockstitch machine proves to be an indispensable tool for fashioning the future of textiles.

The Versatility of the Dressmaker Zig Zag Sewing Machine

Automatic quilting machines have revolutionized the way quilts are made, making the process faster, more efficient, and ultimately more precise. These machines are designed to handle the intricate patterns and stitching required for quilting, which can be difficult to achieve by hand. By automating the quilting process, manufacturers and hobbyists alike can increase their productivity and produce high-quality quilts with ease.

sewing machine needle for faux leather. It's always a good idea to have a few different sizes on hand to test and see which one works best for your specific project.

The backstitch is a fundamental sewing technique that serves to secure the start and end of a seam. Traditionally, this process required the sewist to manually reverse the stitching at both ends of a seam, which could be tedious and time-consuming. With the advent of sewing machines equipped with an automatic backstitch feature, this tedious step has been streamlined. The machine automatically stitches backward for a few stitches, locking the seam in place without any manual intervention.

While both spent $1000 over six years, Jane had the advantage of a machine that could handle more complex projects, ensuring she didn’t turn down work or compromise on quality.

Additionally, the ability to use double needles allows for stunning decorative stitching on quilts. Whether it's creating intricate patterns or adding a contrasting color for visual interest, this machine opens up new avenues for creativity.