2. Spring Specifications

MBHD Carbon Steel: Medium basic carbon cold drawn spring wire per ASTM 227, suitable for parts subjected to average stress and applications; also suited to static orvery low cycles

Music Wire: Spring wire, per ASTM-228, good for parts subjected to high stresses and requiring good thermal properties. For temperatures up to 250°F

Type 302/304 Stainless Steel: Springs are manufactured to meet ASTM-A313, a high quality wire. For temperatures up to 550°F. Slightly magnetic. It is the most widelyused stainless spring wire because of high corrosion resistance properties and good tensile strength.

Black Oxide Coating (good) or Zinc Plating (better):improves the corrosion resistance of HDMB Carbon Steel and Music Wire

Passivation:an acid treatment performed on Stainless Steel Wire to remove contaminants and improve corrosion resistance

Nickel-coated Stainless Steel Springs: made from Suzuki™ Wire®, Nippon-Seisen wire and Sumiden® Type 302 nickel-coated stainless steel for superior corrosionresistance particularly in marine environments. Nickel plating is used in electronics because it provides a good surface for soldering, prevents tarnishing, and conductselectricity well.

4. Lò Xo Đặc Biệt (Specialty Springs)

In conclusion, light compression springs are an essential component in a wide array of applications, offering benefits such as weight reduction, versatility, and improved durability. As industries continue to prioritize efficiency and innovation, the demand for lightweight and reliable components will only grow. Understanding the key features and applications of light compression springs is crucial for engineers and manufacturers seeking to enhance their products and remain competitive in an ever-evolving market. Their role in modern technology underscores the importance of striving for lighter, stronger, and more efficient solutions in both design and application.

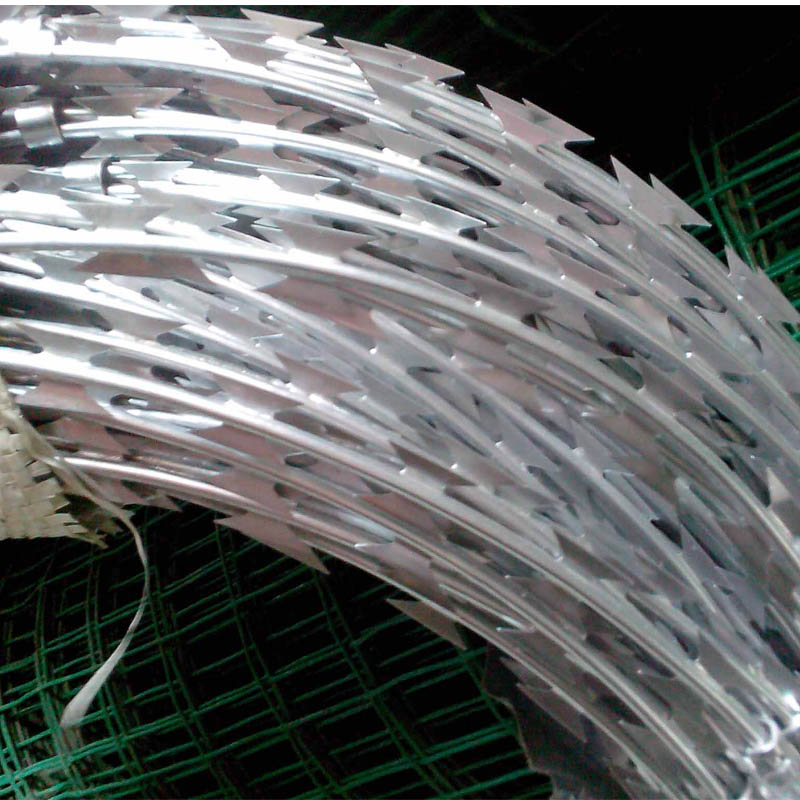

3. Quantité commandée Comme dans de nombreuses industries, l'économie d'échelle joue un rôle crucial dans le coût total. Les commandes en gros peuvent permettre des réductions significatives sur le prix unitaire, rendant le coût du treillis métallique plus attrayant pour les entrepreneurs et les constructeurs.