These belts are designed to operate efficiently, minimizing energy loss during power transmission. This efficiency translates to lower operational costs, making them an economical choice for long-term use.

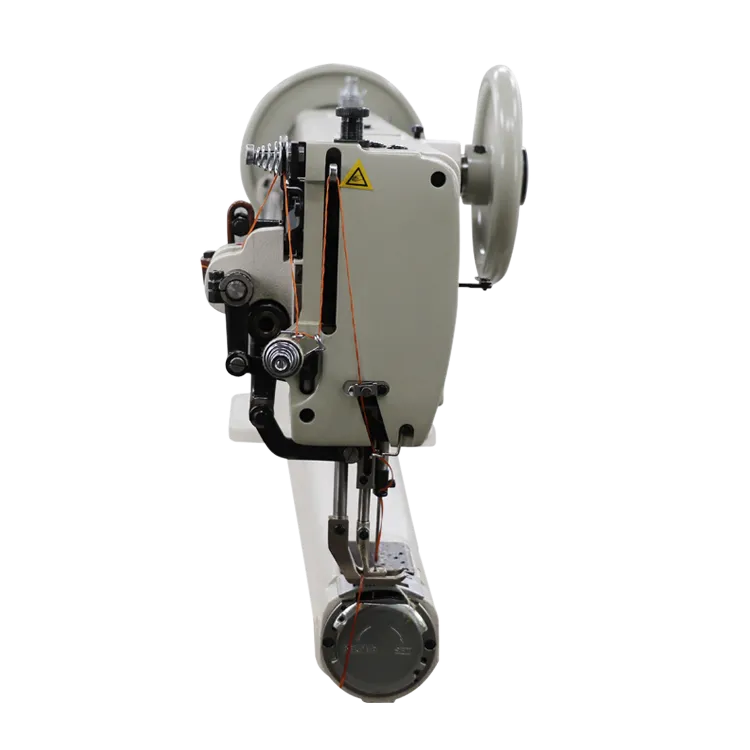

For those involved in the textile and garment industry, understanding the intricacies of hi-speed lockstitch sewing machines is essential. Their significance in improving production efficiency and ensuring quality craftsmanship cannot be overlooked. In a world where fast and reliable manufacturing processes drive success, investing in a hi-speed lockstitch sewing machine is a step towards achieving excellence in sewing operations.

Another critical aspect of needle positioning is the tension of the thread. As you pull the thread through the leather, be cautious not to pull too tightly, as this can cause puckering or warping of the leather. Maintaining a balanced tension allows for a smoother finish and enhances the overall appearance of the stitching.

- In addition to their speed and strength, hi-speed lockstitch machines are also known for their precision. These machines are equipped with advanced tension control systems that help to ensure even stitching and prevent thread breakage. This level of precision is crucial for creating high-quality garments that look professional and are built to last.

The versatility of overlockers allows them to handle a wide range of fabrics, from lightweight knits to heavy denim. This adaptability is particularly important as fashion trends shift and materials evolve. With the rise of stretchy, knit fabrics in fashion, overlockers have become increasingly important in ensuring the comfort and durability of garments.

Triple feed sewing machines take the capabilities of compound feed machines a step further by incorporating an additional feed mechanism. In a triple feed system, the needle feed, drop feed, and walking foot work in tandem with an upper feed mechanism. This setup provides even greater control over fabric movement, making it ideal for intricate and demanding sewing tasks.The primary advantage of triple feed sewing machines is their superior handling of challenging materials. The combined action of the four feed mechanisms ensures precise fabric control, even when working with slippery or stretchy fabrics. This makes triple feed machines an excellent choice for sewing items such as automotive interiors, marine upholstery, and heavy-duty outdoor gear.Triple feed sewing machines also excel in maintaining stitch consistency. The additional feed mechanism enhances the machine’s ability to produce uniform stitches, regardless of fabric type or thickness. This level of precision is essential for achieving high-quality results in complex sewing projects.

The Rise of Handheld Sewing Machines for Thick Fabrics

5. Feed Mechanism A reliable feed mechanism is vital for smooth sewing, especially with heavier fabrics. Look for machines that have a strong feed dog system or an adjustable presser foot that can accommodate bulky materials.

what is a good heavy duty sewing machine

Double needle sewing machines allow for a variety of decorative stitching techniques that can add a unique touch to leather items. The parallel lines of stitching not only reinforce seams but also enhance the aesthetic quality of the finished product. This capability is particularly beneficial for high-end leather goods, where visual appeal is as important as functionality. The option to choose different needle sizes and thread colors further expands creative possibilities, making it easier for artisans to personalize their creations.

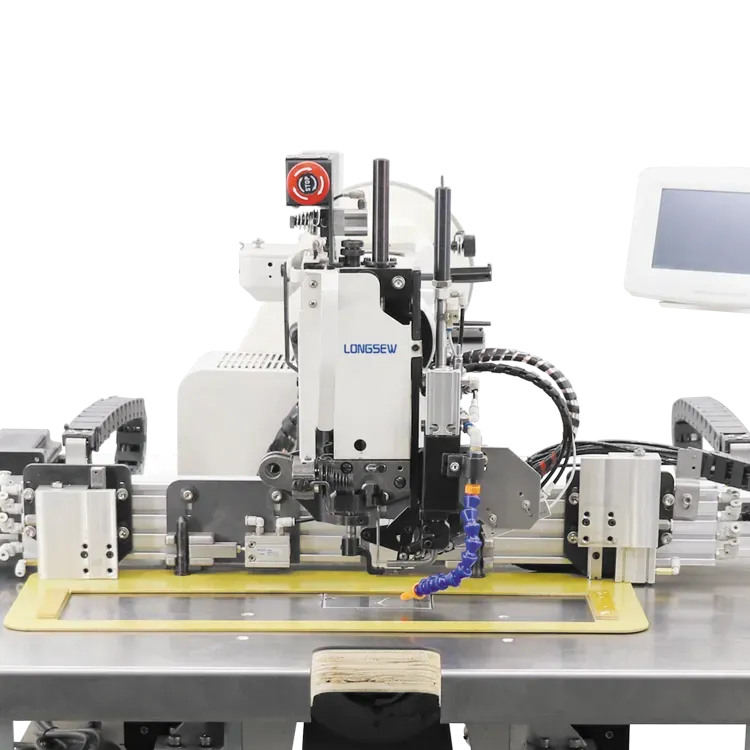

The applications of CNC stitching machines extend beyond clothing production; they also play a crucial role in the automotive, aerospace, and upholstery industries. In the automotive sector, for example, CNC stitching machines are used to create intricate interior designs, ensuring consistency and quality in seat covers and other fabric elements. In aerospace, they contribute to the production of lightweight, durable materials essential for passenger safety and comfort.

Custom Accessories: Custom accessories refer to purses, belts, hats, and specialty pouches that are uniquely tailored or designed.

The Durby Zig Zag Sewing Machine A Comprehensive Analysis of Price and Value

One of the key advantages of the modern bobbin shuttle hook is its ability to handle a wide range of fabrics, from delicate silks to heavy-duty denim. This versatility is crucial for textile manufacturers who need to adapt to different projects quickly. The precision engineering of the hook ensures that stitches remain consistent, even under varying tensions and fabric types. Additionally, advancements in materials have led to stronger and more durable hooks, thereby extending the lifespan of sewing machines and reducing maintenance costs.

In conclusion, choosing the right upholstery machine needles is a critical step in achieving high-quality results in your upholstery projects. By considering factors such as fabric type, thread thickness, and stitching type, you can select the appropriate needle for the job and ensure smooth and consistent stitching. Investing in high-quality needles and regularly replacing them as needed will help you maintain the integrity of your upholstery work and achieve professional results every time.

When sewing with a two needle stitch, it is advisable to practice on scrap fabric before working on the final project. This helps in adjusting settings and familiarizing oneself with the machine’s behavior when using two needles. Once comfortable, the seamstress can confidently move on to larger projects, exploring various designs and applications.

4. Adjustable Presser Foot Pressure Upholstery fabrics vary greatly in thickness and texture. An adjustable presser foot pressure allows tailors to modify the force exerted on the fabric, ensuring a consistent sewing experience and minimizing the risk of fabric puckering.

Conclusion

Another big factor is how much it will cost to purchase the device. Because the heavy-duty machine has been designed to do perform a wider range of tasks, it will tend to be more expensive. You might also be expected to pay higher electricity costs. This can be compared with a high-quality regular machine, that only costs a few hundred dollars to purchase and has much lower running costs.

2. Sewing Straight Lines

What is a Double Needle Long Arm Sewing Machine?

Advantages of Hand Crank Sewing Machines for Leather