timing belt e-scooter 535-5m-15

Choosing the Right Motorcycle Riding Belt

The popularity of the belt flat in fashion and its functionality in mechanical systems speak to a broader trend the integration of style and efficiency across various industries. Customers today are more discerning than ever, seeking products that not only fit their needs but also reflect their personal style and values. The evolution of the belt flat, therefore, is indicative of a shifting paradigm where design meets utility.

1. Follow Manufacturer Guidelines The best way to determine when to replace your timing belt is to follow the manufacturer's recommendations. This typically ranges from 60,000 to 100,000 miles, depending on the specific vehicle model and driving conditions.

4. Additional Repairs Sometimes, replacing a fan belt can unveil other underlying issues, such as a malfunctioning tensioner or other components related to the serpentine system. These additional parts and labor can increase the overall cost of the service.

In the realm of industrial machinery and equipment, the importance of components that ensure optimal functionality and efficiency cannot be overstated. Among these components, V belts play a critical role. These flexible, rubber-based transmission belts are crucial for transferring power between rotating shafts in various applications, making them an essential element in industrial design and engineering.

In Honda vehicles, V belts play an essential role in the functionality of vital systems. The engine generates power that is transmitted to different components through the V belt system. For instance, when the engine runs, the V belt rotates the alternator to generate electrical power for the vehicle's electrical systems, including lights and infotainment systems. Additionally, V belts help power the water pump that circulates coolant throughout the engine, maintaining an optimal operating temperature.

Additionally, operational conditions such as extreme temperatures, dust, or moisture can adversely affect the lifespan of flat belts. Therefore, selecting the right material based on the specific environmental conditions is crucial for optimal performance.

As technology evolves, so too does the world of conveyor belts. The future is likely to witness advancements such as

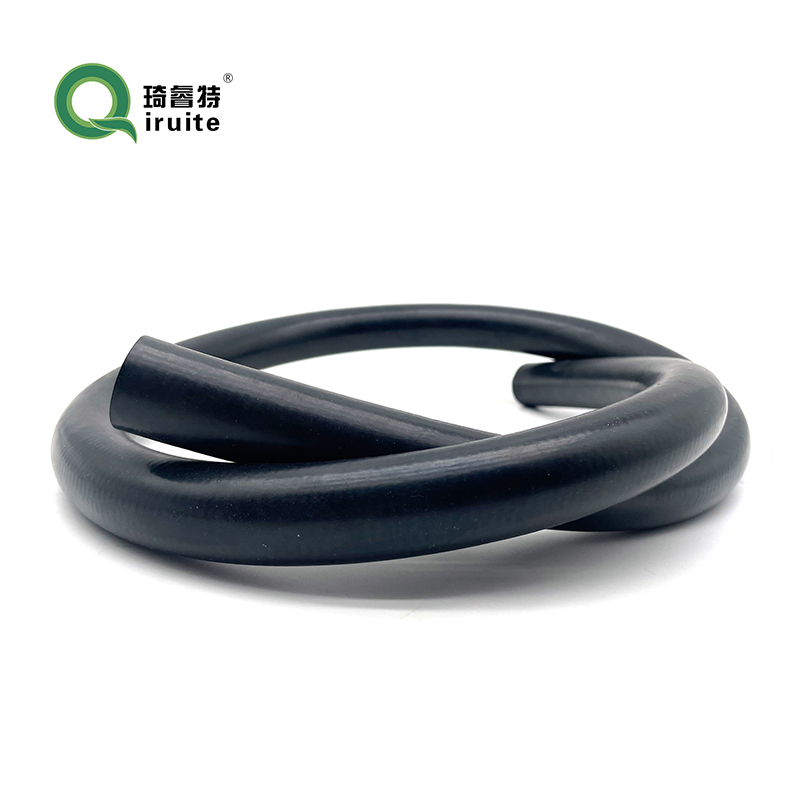

This not only enhances the vehicle’s maneuverability but also extends the lifespan of the hose itself This not only enhances the vehicle’s maneuverability but also extends the lifespan of the hose itself

This not only enhances the vehicle’s maneuverability but also extends the lifespan of the hose itself This not only enhances the vehicle’s maneuverability but also extends the lifespan of the hose itself land cruiser 100 power steering hose.

land cruiser 100 power steering hose.

Price and Value: Compare prices from different suppliers while considering the quality and features of the hose. Choose a hose that offers the best value for your budget, balancing affordability with durability and performance.

You may need to use a pair of pliers to help loosen any stubborn clamps or fittings You may need to use a pair of pliers to help loosen any stubborn clamps or fittings

You may need to use a pair of pliers to help loosen any stubborn clamps or fittings You may need to use a pair of pliers to help loosen any stubborn clamps or fittings miata power steering hose replacement. Once the old hose is removed, clean the area thoroughly with a clean cloth to remove any debris or rust.

miata power steering hose replacement. Once the old hose is removed, clean the area thoroughly with a clean cloth to remove any debris or rust. The diagram may also include details about the specific diameter and length of each hose, which are crucial parameters for ensuring the proper functioning of the system The diagram may also include details about the specific diameter and length of each hose, which are crucial parameters for ensuring the proper functioning of the system

The diagram may also include details about the specific diameter and length of each hose, which are crucial parameters for ensuring the proper functioning of the system The diagram may also include details about the specific diameter and length of each hose, which are crucial parameters for ensuring the proper functioning of the system ford 6.0 power steering hose diagram.

ford 6.0 power steering hose diagram.Routing and Positioning: Properly route the hoses to avoid sharp bends, kinks, or obstructions that could restrict refrigerant flow. Keep the hoses away from hot engine components and moving parts to prevent damage.

Power steering is an essential component in modern vehicles, providing drivers with added assistance in steering. The power steering hose is a crucial part of the power steering system in a vehicle, helping to deliver power steering fluid from the pump to the steering gear.

isuzu power steering hose. Its compact size and lightweight design contribute to the vehicle's overall efficiency, as they do not add unnecessary weight or bulk. This, in turn, impacts fuel consumption and overall vehicle performance.

isuzu power steering hose. Its compact size and lightweight design contribute to the vehicle's overall efficiency, as they do not add unnecessary weight or bulk. This, in turn, impacts fuel consumption and overall vehicle performance.If you are experiencing issues with your power steering hose blowing off, it is important to address the problem promptly. Ignoring the issue can lead to further damage to your vehicle and potentially put your safety at risk. Consult with a qualified mechanic to diagnose the root cause of the problem and make the necessary repairs to ensure that your power steering system is functioning properly.

One of the most common types of fire hose pipe couplings is the storz coupling. This type of coupling features symmetrical halves that can be easily connected and disconnected with a simple twist motion. Storz couplings are known for their quick and secure connection, making them a popular choice for firefighting applications.

Use a wrench or socket to loosen any fittings or clamps that secure the hose in place Use a wrench or socket to loosen any fittings or clamps that secure the hose in place

Use a wrench or socket to loosen any fittings or clamps that secure the hose in place Use a wrench or socket to loosen any fittings or clamps that secure the hose in place nissan maxima power steering hose replacement. Be careful not to damage the hose during removal.

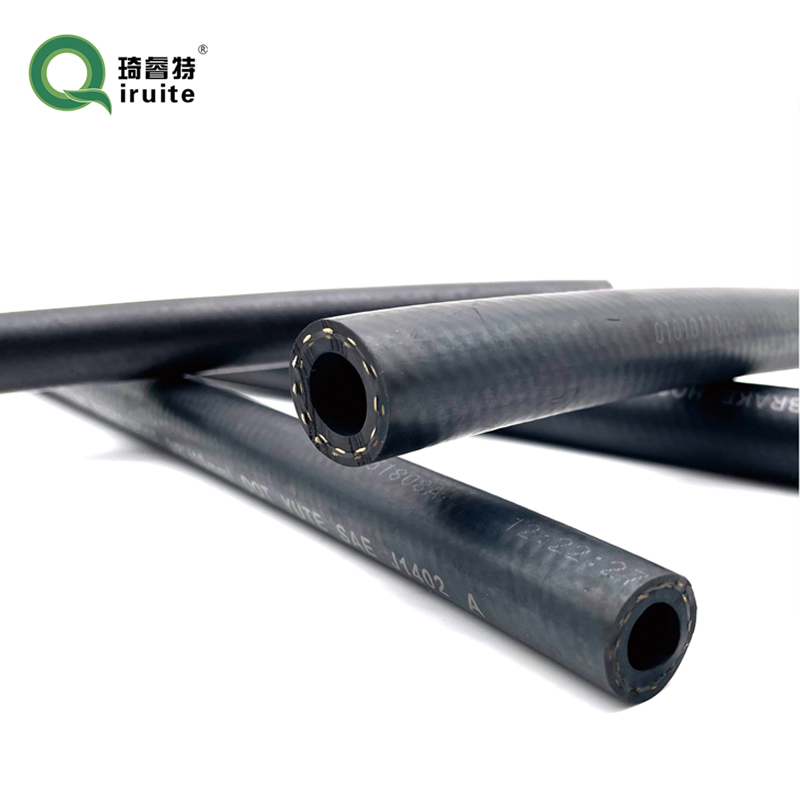

nissan maxima power steering hose replacement. Be careful not to damage the hose during removal. They are subjected to pressure and temperature tests to verify their ability to withstand the hydraulic forces generated by power steering systems They are subjected to pressure and temperature tests to verify their ability to withstand the hydraulic forces generated by power steering systems

They are subjected to pressure and temperature tests to verify their ability to withstand the hydraulic forces generated by power steering systems They are subjected to pressure and temperature tests to verify their ability to withstand the hydraulic forces generated by power steering systems impala power steering hose. This rigorous testing guarantees that these hoses can handle even the toughest driving scenarios, from city commutes to off-road adventures.

impala power steering hose. This rigorous testing guarantees that these hoses can handle even the toughest driving scenarios, from city commutes to off-road adventures.

This adaptability is vital, especially in vehicles with complex steering geometries This adaptability is vital, especially in vehicles with complex steering geometries

This adaptability is vital, especially in vehicles with complex steering geometries This adaptability is vital, especially in vehicles with complex steering geometries power steering hose napa.

power steering hose napa.