Heavy duty floor tape is a crucial tool for maintaining safety and organization in various settings. From warehouses and factories to hospitals and schools, floor tape is used to mark walkways, indicate hazardous areas, and create clear boundaries.

Red insulation tape is more than just a simple material; it is a versatile tool that enhances safety and efficiency across a wide range of applications. From electrical work to creative projects, its durability, ease of use, and distinct color make it an invaluable asset. Whether you are a professional electrician or a DIY enthusiast, investing in quality red insulation tape can be a game-changer in ensuring safe and effective results in your projects.

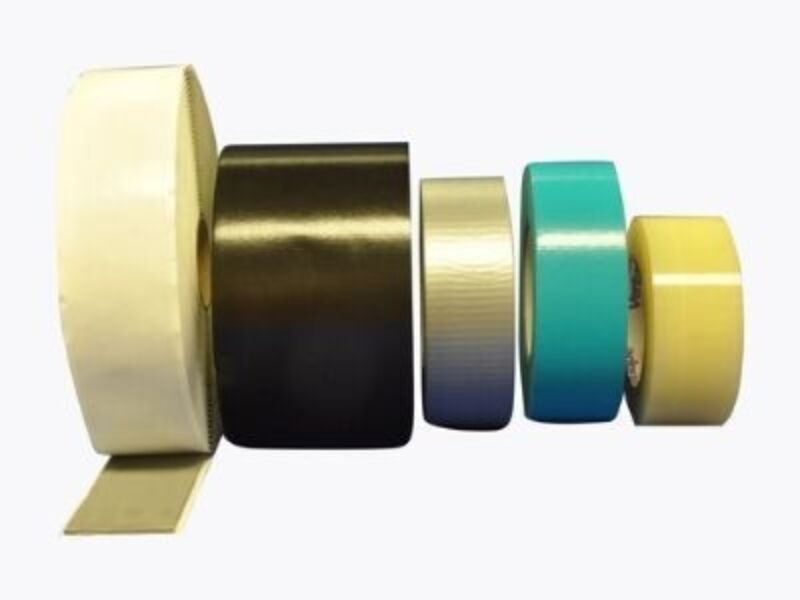

To avoid these problems, let’s look at the most important factors for choosing the best adhesive tape for your needs. This tape guide is not a fully-encompassing class on all of the myriad tape options and styles, but it will instruct you on the basics of tape adhesives so that you can make an informed decision. Before describing specific types of adhesives, let's define some essential tape terminology.

self-adhesive tape.

There are several types of polyethylene film, each with a different density and use. Polyethylene tape is categorized by the tape’s density:

Silicones have been used to formulate adhesive products for decades due to their flexibility, temperature cycling resistance, chemical resistance, and wide range of possible material properties.

TAPE IS YOUR TRUSTED SOURCE FOR SINGLE COATED TAPES

6. Convenient maintenance: the surface is not sticky, the surface does not stick to the hand, and does not adhere to the contacted surface;

Polyethylene Tape offers a certain degree of water resistance, but it is not entirely waterproof. Polyethylene is a thermoplastic polymer known for its resistance to moisture and water absorption. Therefore, Polyethylene Tape can provide a barrier against water and offer some protection in applications where exposure to moisture is a concern.

What is Silicone Self-Adhesive Tape?

When it comes to tackling repairs, having the right tools and materials at your disposal can make all the difference. If you're in the market for tapes to address your repair needs, understanding the distinctions between various options is crucial. TAPE, a professional manufacturer with 18 years of experience in producing high-quality tapes, can provide valuable insights into the differences between two commonly used products: Silicone Rubber Tape and Rubber Repair Tape.

Key Advantages of Butyl Rubber Roofing Sheets

Double-Coated Polyethylene Foam Tape

how to use self amalgamating repair tape. Make sure to overlap the tape as you wrap it around to ensure a secure bond.

When you think of types of electrical tape, you probably imagine it in black. However, manufacturers produce electrical insulation tape in almost every color of the rainbow. The varying colors indicate voltage protection and insulation. It’s vital to use the right colored tape—an incorrect tape color puts technicians at risk of insufficient voltage shielding: