- Service manual for your specific vehicle

In contrast, the timing belt is a critical component that ensures the synchronization between the engine's crankshaft and camshaft. This synchronization is vital for proper engine timing, affecting the opening and closing of engine valves. Unlike the serpentine belt, the timing belt is typically enclosed and less visible. It has a predetermined lifespan and should be replaced at regular intervals specified by the vehicle manufacturer. A failed timing belt can result in catastrophic engine damage, highlighting the importance of regular maintenance.

In construction, it is used as a plastering material, improving the strength and durability of building structures In construction, it is used as a plastering material, improving the strength and durability of building structures

In construction, it is used as a plastering material, improving the strength and durability of building structures In construction, it is used as a plastering material, improving the strength and durability of building structures hec vs hpmc.

hec vs hpmc.

hydroxypropyl methylcellulose price. The price of HPMC in the pharmaceutical industry is justified by its crucial role in ensuring the efficacy and safety of medications.

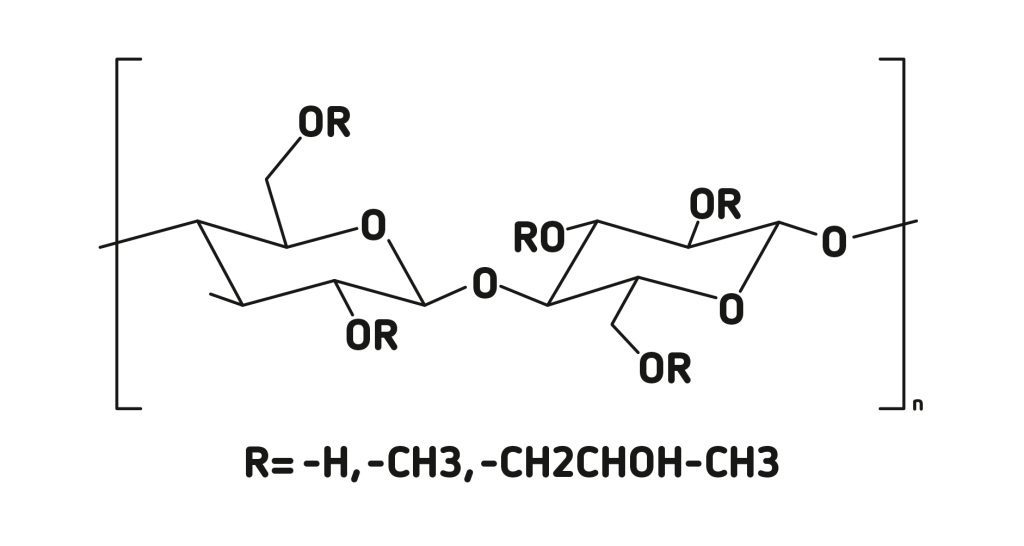

Appearance: both HPMC and HEC are white powder. HPMC is a Non-ionic compound, a non-reactive viscoelastic polymer. HEC raw material is Alkaline Cellulose and Ethylene Oxide.

Hydroxypropyl methylcellulose (HPMC) is a key ingredient in many vitamins and dietary supplements, playing a vital role in the formulation and efficacy of these products. This compound is a derivative of cellulose, a naturally occurring polymer that makes up plant cell walls. Making HPMC by modifying cellulose requires the addition of hydroxypropyl and methyl groups, resulting in a water-soluble multifunctional substance with a wide range of applications.

hydroxypropyl methyl cellulose cas. HPMC is also used as a fat replacer in low-fat foods to mimic the mouthfeel of full-fat products.

Seit 1998 gibt es auch pflanzliche Kapseln auf dem Markt. Mit HPMC steht den Verbrauchern ein völlig unbedenkliches, pflanzliches Produkt zur Verfügung, sodass auch Veganer oder Vegetarier und Menschen, die aufgrund ihrer Religion auf Gelatine verzichten,eine Alternative zu Gelatine-Kapseln haben.

HPMC-Kapseln halten hohen Temperaturen sowie hoher Luftfeuchtigkeit stand und besitzen einen geringen Eigenfeuchtigkeitsgehalt. Dadurch sind die Kapselhüllen zur Aufbewahrung von feuchtigkeitsempfindlichen Zutaten geeignet. Sie schützen somit ihren Inhalt vor allen Arten von Schwankungen wie beispielsweise Temperaturschwankungen und Feuchtigkeit. HPMC-Kapseln sind somit

hpmc manufacturer. In construction, it enhances the workability of mortar and plaster, while in the food industry, it serves as a thickening and stabilizing agent.

hpmc manufacturer. In construction, it enhances the workability of mortar and plaster, while in the food industry, it serves as a thickening and stabilizing agent.If you enjoyed this article, I’ve written about psyllium husk, mono- and diglycerides of fatty acids, lecithin and xanthan gum too.

how to dissolve hpmc in water. Mix the HPMC and Water Begin by adding the HPMC to the water slowly, while stirring constantly. It is important to mix the HPMC and water thoroughly to ensure even distribution. You can use a spoon, whisk, or electric mixer for this purpose. Avoid using a blender or food processor, as these can generate excessive heat and damage the HPMC.

how to dissolve hpmc in water. Mix the HPMC and Water Begin by adding the HPMC to the water slowly, while stirring constantly. It is important to mix the HPMC and water thoroughly to ensure even distribution. You can use a spoon, whisk, or electric mixer for this purpose. Avoid using a blender or food processor, as these can generate excessive heat and damage the HPMC.