...

2025-08-14 17:30

277

...

2025-08-14 17:19

1051

...

2025-08-14 17:06

761

...

2025-08-14 17:05

127

...

2025-08-14 16:48

233

...

2025-08-14 16:24

2916

...

2025-08-14 16:23

1121

...

2025-08-14 16:03

1257

...

2025-08-14 15:20

537

...

2025-08-14 15:13

2828

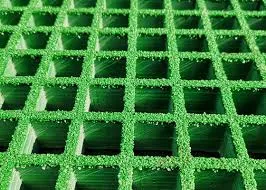

- Fiberglass, or glass-reinforced plastic (GRP), is a composite material made by combining glass fibers with a polymer resin matrix. This composition imparts exceptional strength and resilience to the tanks, making them resistant to corrosion, weathering, and impact. Unlike traditional metal or concrete tanks, fiberglass tanks do not rust, crack, or leach harmful chemicals, ensuring the safety and integrity of the stored substances.

- The Versatile World of Large Drill Bits

- 1. Energy Efficiency By reducing heat loss or gain, fiberglass insulation tanks help to save energy and reduce operating costs. This is especially important in commercial and industrial applications where large amounts of energy are used to heat or cool liquids.

- Next comes the application of a primer, which serves as a bonding agent between the old surface and the new layer of fiberglass

This makes it an ideal choice for applications where exposure to corrosive substances is inevitable, such as in chemical processing plants or offshore oil rigs This makes it an ideal choice for applications where exposure to corrosive substances is inevitable, such as in chemical processing plants or offshore oil rigs

This makes it an ideal choice for applications where exposure to corrosive substances is inevitable, such as in chemical processing plants or offshore oil rigs This makes it an ideal choice for applications where exposure to corrosive substances is inevitable, such as in chemical processing plants or offshore oil rigs corrosion resistant frp. The polymer matrix also acts as a protective barrier, shielding the fibers from external elements and preventing corrosion from occurring.

corrosion resistant frp. The polymer matrix also acts as a protective barrier, shielding the fibers from external elements and preventing corrosion from occurring. The narrower base effectively creates a larger annulus around the drill string, allowing for improved circulation of drilling fluids The narrower base effectively creates a larger annulus around the drill string, allowing for improved circulation of drilling fluids

The narrower base effectively creates a larger annulus around the drill string, allowing for improved circulation of drilling fluids The narrower base effectively creates a larger annulus around the drill string, allowing for improved circulation of drilling fluids tapered drill string. This enhanced flow rate carries away cuttings more efficiently, maintaining a cleaner borehole and improving the overall drilling process. Consequently, operators can achieve faster penetration rates and higher quality drill holes, ultimately leading to cost savings and increased productivity.

tapered drill string. This enhanced flow rate carries away cuttings more efficiently, maintaining a cleaner borehole and improving the overall drilling process. Consequently, operators can achieve faster penetration rates and higher quality drill holes, ultimately leading to cost savings and increased productivity. Operators require proper training and protective gear, including earplugs, safety glasses, and steel-toed boots, due to the loud noise and potential hazards associated with the tool's operation Operators require proper training and protective gear, including earplugs, safety glasses, and steel-toed boots, due to the loud noise and potential hazards associated with the tool's operation

Operators require proper training and protective gear, including earplugs, safety glasses, and steel-toed boots, due to the loud noise and potential hazards associated with the tool's operation Operators require proper training and protective gear, including earplugs, safety glasses, and steel-toed boots, due to the loud noise and potential hazards associated with the tool's operation compressed air jack hammer. Regular maintenance is essential to ensure the equipment remains in optimal condition and to prevent accidents.

compressed air jack hammer. Regular maintenance is essential to ensure the equipment remains in optimal condition and to prevent accidents. In percussive drilling, this force combines rotary motion with a pulsating action, enhancing the drilling efficiency In percussive drilling, this force combines rotary motion with a pulsating action, enhancing the drilling efficiency

In percussive drilling, this force combines rotary motion with a pulsating action, enhancing the drilling efficiency In percussive drilling, this force combines rotary motion with a pulsating action, enhancing the drilling efficiency rock drill parts.

rock drill parts.

impact driver drill bits. The quick rotational motion of impact drivers allows you to start and stop driving screws with precision, making it easier to achieve a flush finish without overdriving or stripping the fastener.

frp fuel tank. They can be manufactured in various shapes and sizes, accommodating different space constraints and volume requirements. Customization options allow for tailored solutions that fit specific operational needs.

frp fuel tank. They can be manufactured in various shapes and sizes, accommodating different space constraints and volume requirements. Customization options allow for tailored solutions that fit specific operational needs.