Installation and Maintenance

Benefits of High-Quality Ribbed Belts

Tips voor het Besparen op Timing Belt Kosten

3. Labor Fees Labor costs can vary widely depending on the region and the shop’s reputation. Dealerships typically charge more than independent garages, and urban areas may have higher labor rates than rural locations. Some DIY enthusiasts may choose to replace the belt themselves, which can save significant money.

5. Medical Equipment Precision is essential in medical devices, making synchronous belts integral components in equipment such as MRI machines and robotic surgical systems.

4. Versatility Raw edge V-belts can be used in a wide range of applications, from agricultural machinery to industrial equipment. Their adaptability makes them a popular choice among engineers and technicians.

In the context of public key cryptography, the significance of terms like PK 708 proliferates. Public key infrastructure (PKI) is fundamental to securing communications on the internet. It ensures data confidentiality, integrity, and authentication between communicating parties. Each key pair, consisting of a public and a private key, facilitates secure data transmission and protects against unauthorized access.

3. Durability and Longevity Made from robust rubber compounds, these drive belts are designed to withstand the rigors of constant use. They are resistant to abrasion, heat, and environmental factors, making them suitable for both indoor and outdoor applications. The durability of round rubber drive belts results in decreased maintenance costs and reduced downtime for machinery, thus enhancing overall productivity.

4. Loss of Power Steering If the power steering belt fails, the driver may experience difficulty steering, indicating a need for immediate attention.

Current Market Trends

3. Polyurethane Tooth V Belts Known for their excellent durability, polyurethane belts withstand harsh conditions and are often used in applications where oils, chemicals, or extreme temperatures are present.

The cost of auto parts and services can vary based on geographic location. In urban areas or regions with higher living costs, prices for timing belts and their installation might be elevated compared to more rural areas. Market dynamics, such as demand and supply for specific vehicle parts, can influence pricing as well.

2. Durability Made from high-quality rubber and reinforced with materials such as polyester or steel, 5pk belts are designed to withstand extreme temperatures and pressures. Their robust construction provides resistance to wear and tear, making them a reliable choice for many vehicles.

Siz də W124 modelini satın alaraq, bu avtomobilin təqdim etdiyi unikal sürüş məmnuniyyətini yaşamağa başlaya bilərsiniz. Unikal dizaynı və etibarına əlavə olaraq, Mercedes W124-nin öz kolleksiyanıza qatılması, avtomobil dünyasında sizin üçün əvəzolunmaz bir önəm kəsb edəcək.

The timing belt in your Peugeot 206 is not just a rubber band; it’s a critical part of your engine’s operation and is key to maintaining your vehicle's performance. Adhering to manufacturer-recommended replacement intervals, staying vigilant for warning signs, and consulting professionals for replacements can save you from significant damage and costly repairs. Taking care of your timing belt today will ensure smoother rides and a longer life for your Peugeot 206 tomorrow.

The Charm of Vintage Leather Kidney Belts

The designation 8PK refers to a specific type of V-belt characterized by its cross-section and length. The 8 indicates that the belt has a width of 8 millimeters, and K denotes that it is a type known for its durability and high load-carrying capacity. V-belts, in general, are made of high-quality rubber and are designed to engage with pulley systems, transferring rotational motion and power efficiently.

- Consumer Electronics Many printers and other devices utilize polyurethane belts due to their ability to operate quietly and maintain precision in moving parts.

Conclusion

The evolution of Japan car engines is a remarkable narrative of innovation, performance, and sustainability. From the rudimentary designs of the post-war era to the sophisticated hybrid and electric technologies of today, Japanese engineers have consistently demonstrated their ability to adapt and lead in an ever-changing automotive landscape. As we look to the future, it is clear that Japan will continue to play a pivotal role in shaping the next generation of automotive technology and performance.

For the 5A engine, the timing belt typically needs to be replaced every 60,000 to 100,000 miles, although specific recommendations can vary based on the manufacturer’s guidelines and driving conditions. It is essential to consult the vehicle’s owner manual for the recommended replacement interval. Signs that may indicate a need for replacement include visible wear, such as cracks, fraying, or glazing on the belt surface. Additionally, if one hears unusual sounds from the engine area, such as a ticking or grinding noise, it may be a sign that the timing belt is failing.

Recognizing the early signs of a worn timing belt can save car owners from costly repairs and engender safety. Key indicators of a failing timing belt include

- 2. Labor Costs If you decide to have a professional mechanic replace the belt, labor costs will factor into the overall expenditure. Labor can range from $50 to $150 per hour, and since replacing a dynamo belt usually takes about 1 to 2 hours, you may see an additional charge of $50 to $300.

- Visual Inspection Regularly inspect the belt for signs of wear, cracking, or fraying. Early detection can prevent more significant issues.

4. Avoid Overloading Avoid exceeding the manufacturer's recommended load limits. Overloading can strain the V-belt and lead to accelerated wear or failure.

Signs of a Worn Timing Belt

5. Reputation Mitsuboshi has built a strong reputation in the automotive aftermarket as a trusted supplier. Many mechanics and car manufacturers rely on their products due to consistent performance and quality.

Conclusion

Disadvantages of Belts

1. Increased Performance With its robust design and advanced engineering, the Cummins Belt 3289930 contributes to the overall performance of the engine. A well-functioning belt ensures optimal power transfer and keeps the engine running smoothly, which can lead to improved fuel efficiency and lower operational costs.

Understanding B Series Timing Belts A Comprehensive Overview

To ensure optimal performance and longevity of the V-belt B60, regular maintenance is key. Here are a few tips

Molded ribbed poly V belts, often referred to simply as Poly V belts, are constructed from high-quality rubber compounds and are designed with multiple ribs running longitudinally along the belt's surface. This ribbed profile increases the contact area between the belt and the pulleys it drives, resulting in enhanced grip and reducing the chances of slippage. Unlike conventional V belts that typically have a wider, flat surface, the ribbed design allows for greater flexibility, enabling these belts to bend around smaller pulley diameters without compromising performance.

1. Increased Efficiency The design of Poly-V TB2 belts minimizes energy loss during power transmission. The flat profile reduces friction and heat generation, leading to lower energy consumption. This efficiency is crucial for modern applications where sustainability and energy savings are priorities.

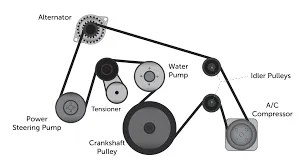

The serpentine belt is a crucial component of your vehicle's engine, playing an essential role in driving multiple peripheral devices. This single, continuous belt is responsible for powering essential systems such as the alternator, power steering pump, water pump, air conditioning compressor, and more. Over time, serpentine belts can wear out and may need to be replaced. Understanding how to select and purchase the right serpentine belt for your vehicle is key to maintaining optimal performance.

2. Imperial Sizes In the Imperial system, V-belts are often measured in inches. The most common sizes include

First and foremost, it is essential to clarify what 8PK1420 represents. In certain technological contexts, such as software engineering or product development, alphanumeric codes are employed to designate particular models, versions, or specifications of a product. In this case, 8PK1420 could represent a unique identifier for a component, software package, or even a set of protocols in a larger system. The use of such codes is critical in maintaining organization and clarity, especially in industries characterized by rapid advancements and continuous updates.

Advantages of V-Ribbed Belt Pulleys

Understanding the Cost of a Car Serpentine Belt

Ignoring the need for timing belt replacement can lead to catastrophic engine failure. Many manufacturers recommend replacing the timing belt every 60,000 to 100,000 miles, but it is essential to consult your owner's manual for specific recommendations. Regular maintenance ensures that your vehicle operates smoothly and can save you from more significant expenses down the line.

Understanding Timing Belts The Importance of OEM Parts

In conclusion, the price of drive belts is influenced by a myriad of factors, including type, brand, vehicle compatibility, and market dynamics. Buyers must remain informed and consider various aspects before making a purchase to ensure they get the best value while maintaining the reliability of their vehicles.

Considerations

While V-belts are durable, they do require some level of maintenance to ensure optimal performance. Regular inspections for wear, alignment, and tension are crucial. Signs of wear, such as cracking or fraying, indicate that the belt should be replaced to prevent system failure. When replacing a V-belt, it's essential to ensure that the new belt is of the correct size and type to avoid compatibility issues.

For det første er 6PK1138 designet med brugervenlighed i tankerne. Med et intuitivt interface kan alle – uanset teknisk baggrund – nemt navigere i systemet. Det betyder, at både teknikere og almindelige brugere kan få glæde af de avancerede funktioner uden at skulle gennemgå en lang læringskurve. Dette demokratiserer teknologien og gør den tilgængelig for alle.

Begin by parking your vehicle on a flat surface and turning off the engine. Engage the parking brake. If your vehicle has been running, allow the engine to cool down as the components can be hot and may cause burns.

V-belts come in various types, each designed for specific applications. The most common types include classical V-belts, narrow V-belts, and cogged V-belts. Classical V-belts are widely used due to their versatility and strength. Narrow V-belts, on the other hand, are designed to handle higher loads in smaller spaces, making them ideal for compact machinery. Cogged V-belts are engineered with notches that enhance flexibility, reducing slippage and improving performance. Each type has its own price point, reflecting its unique characteristics and engineering.

When it comes to the intricate design of modern vehicles, one of the most crucial components often overlooked is the auto drive belt. From the moment you turn the ignition key to the last mile of your journey, the drive belt plays a significant role in ensuring your vehicle operates smoothly and efficiently. This article aims to explore the concept of auto drive belts, their importance, types, maintenance, and signs that indicate when it’s time for a replacement.

The core purpose of a timing belt is to ensure that the engine's valves open and close at the proper intervals in relation to the position of the pistons. This synchronization prevents the pistons from colliding with the valves, which can result in catastrophic engine damage. Timing belts are typically made from durable materials such as rubber, reinforced with nylon or fiberglass to enhance their strength and longevity.

1. Timing Belt The primary belt that synchronizes the engine's parts.