Here's what you need to know about titanium dioxide:

- The workforce in TIO2 factories embodies a diverse range of skills and expertise, reflecting a microcosm of global collaboration. Engineers, chemists, quality assurance specialists, and logistics coordinators work in harmony, each playing a critical role in the complex manufacturing process. This collective effort underscores the importance of teamwork and knowledge-sharing in driving industrial success.

The pricing of lithopone pigments can fluctuate based on several factors, including raw material costs, production processes, and market demand. Typically, wholesale prices reflect the bulk purchasing power, enabling businesses to acquire these materials at a lower cost per unit. Over the years, the market has seen fluctuations in prices due to changes in the supply chain and global economic conditions. It is crucial for buyers to stay informed about these trends to budget effectively and maintain profitability.

lithopone 28-30% factory.

Because of its unique pigment and fine-milled texture, titanium dioxide has become popular over the past century in a wide variety of different products. These include adhesives, paints, plastics, rubbers, textiles, inks, ceramics, and even some pharmaceuticals, foods, and hygiene products.

titanium dioxide rutile tio2 emulsion latex paints manufacturer. Manufacturers utilize high-speed mixing equipment to evenly distribute the pigment particles throughout the emulsion, preventing agglomeration and ensuring consistent product quality. The concentration of rutile TiO2 used depends on the desired level of hiding power and the specific end-use requirements of the paint.

titanium dioxide rutile tio2 emulsion latex paints manufacturer. Manufacturers utilize high-speed mixing equipment to evenly distribute the pigment particles throughout the emulsion, preventing agglomeration and ensuring consistent product quality. The concentration of rutile TiO2 used depends on the desired level of hiding power and the specific end-use requirements of the paint.5. Is EFSA banning titanium dioxide?

Aside from its use in paints, coatings, plastics, and paper, TiO2 is also utilized in a variety of other industrial applications. It is commonly found in cosmetics, sunscreens, and food products, where it serves as a safe and effective whitening agent. TiO2 is also used in the production of ceramics, glass, and textiles, where it enhances their appearance, durability, and resistance to fading.

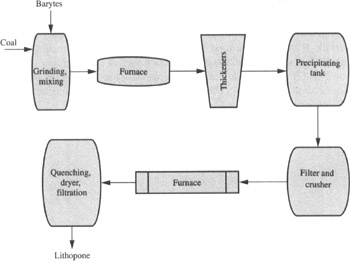

lithopone 28-30% factory.

Application:

1. Due to its rheological and optical properties, Lithopone offers technical and economic advantages wherever organic and inorganic resin systems need to be relatively highly pigmented for specific applications. Lithopone has therefore traditionally been used in putties, mastics, jointing and sealing compounds, primers, undercoats and marking paints. In powder coatings it is possible to replace TiO2 partially, very economically.

2. The low Mohs' hardness of Lithopone leads to low abrasiveness in comparison with TiO2.

3. Lithopone 30 % (= 30% zinc sulfide share) is proven to be of particular use as a TiO2 Substitute in thermoplastic masterbatches. Even at very high pigment loadings it disperses easily. A masterbatch containing 50 % TiO2 and 25 % Lithopone 30 % DS has the same hiding power as one containing 60 %TiO2. Cost savings are strongly related to the price ratio of Lithopone and TiO2 and the price of for example polyethylene or polypropylene.

4. The Lithopone batch has a much higher extrusion rate too. Furthermore the impact strength of many thermoplastics such as PP and ABS can be noticeably improved by using Lithopone as a TiO2 substitute. Generally spoken, Lithopone can be used at loadings up to 80 % by weight without causing polymer breakdown

Moreover, it contributes to the gloves' opacity, preventing see-through and providing additional comfort and confidence to the wearer Moreover, it contributes to the gloves' opacity, preventing see-through and providing additional comfort and confidence to the wearer

Moreover, it contributes to the gloves' opacity, preventing see-through and providing additional comfort and confidence to the wearer Moreover, it contributes to the gloves' opacity, preventing see-through and providing additional comfort and confidence to the wearer titanium dioxide for nitrile gloves factory.

titanium dioxide for nitrile gloves factory.Titanium dioxide is widely used as a color-enhancer in cosmetic and over-the-counter products like lipsticks, sunscreens, toothpaste, creams, and powders. It’s usually found as nano-titanium dioxide, which is much smaller than the food-grade version (7Trusted Source).

precipitated barium sulphate market suppliers. They offer a variety of precipitated barium sulfate products, including those with high purity and specific particle size distributions. Elementis' commitment to sustainability and environmental responsibility has helped them gain a competitive edge in the market.

precipitated barium sulphate market suppliers. They offer a variety of precipitated barium sulfate products, including those with high purity and specific particle size distributions. Elementis' commitment to sustainability and environmental responsibility has helped them gain a competitive edge in the market.