- High Flexibility The ability to bend easily around pulleys makes poly V belts versatile for various applications.

Amalgamating tape is a great alternative to traditional sealing methods such as glue, caulk, or silicone. It is flexible, durable, and can withstand a wide range of temperatures and environments. Whether you are repairing a leaky pipe, sealing an electrical connection, or fixing a broken hose, amalgamating tape is a reliable solution.

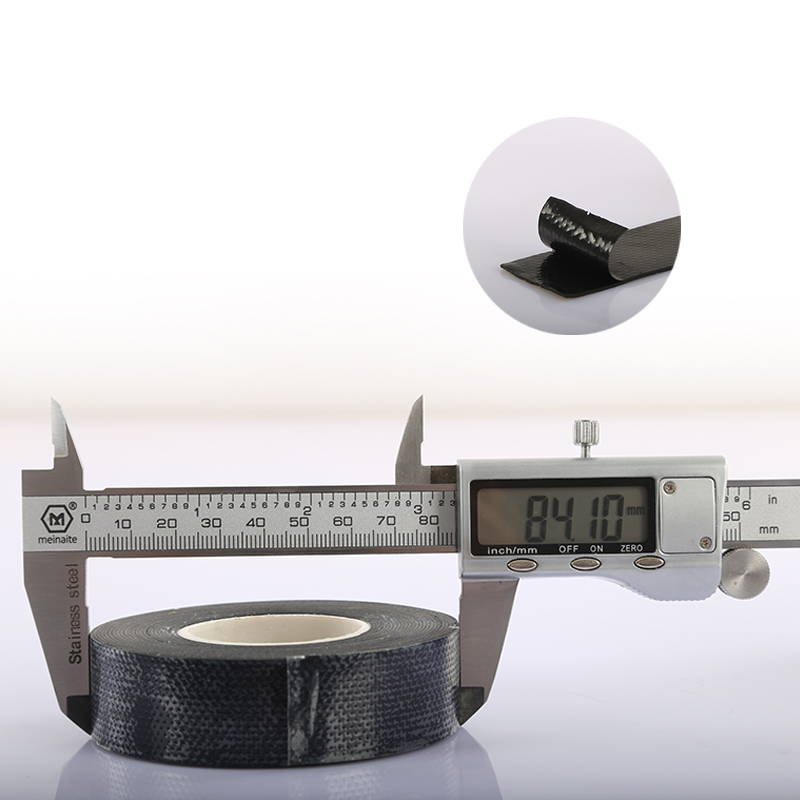

- Rubber splicing tape is a crucial tool in the field of industrial maintenance and repair. One popular type of splicing tape is the 130c% linerless rubber splicing tape, which offers numerous benefits and advantages for those who utilize it.

Moreover, the ease of application and removal enhances its popularity. It adheres well to surfaces but can be removed without leaving a sticky residue, making it suitable for temporary applications. It is also easy to cut, allowing for customization in width and length according to specific needs.

- The first type of intumescent strip is the graphite-based intumescent strip. Graphite-based intumescent strips are known for their high performance in fire resistance and insulation. These strips are capable of expanding up to several times their original size when exposed to high temperatures, creating a barrier that effectively seals off gaps and openings in structures. Graphite-based intumescent strips are commonly used in doors, windows, and other building components to enhance their fire resistance.

It’s important to consider the specific requirements of the application, including temperature range, mechanical stress, chemical exposure, electrical properties, and budget when selecting the most suitable carrier material for adhesive tapes. Each material has its advantages and is chosen based on the specific demands of the application.

Moreover, the aesthetic aspect of Black Flex Tape cannot be overlooked. With its sleek black appearance, it blends seamlessly into many environments, providing a discreet solution for unsightly repairs. This visual appeal is particularly important for those looking to maintain the integrity and appearance of their personal belongings or living spaces.

What is a control box?

self amalgamating electrical tape. It can withstand temperatures ranging from -65°F to 220°F, making it ideal for use in harsh environments. Its waterproof properties also make it a great choice for outdoor electrical repairs, as it can protect against rain and other weather conditions.

self amalgamating electrical tape. It can withstand temperatures ranging from -65°F to 220°F, making it ideal for use in harsh environments. Its waterproof properties also make it a great choice for outdoor electrical repairs, as it can protect against rain and other weather conditions.Application Scenarios: Both tapes are designed with safety in mind, but which one to choose may depend on specific repair needs and environmental factors, Silicone self-adhesive tape is mainly used in electrical insulation, plumbing repairs, wire wrapping, and automotive wire sealing, while the rubber repair tape is mainly used for plumbing and bucket repairs.

Flex Tape Black is a powerful adhesive tape that can be used for a variety of purposes. Measuring 4 inches in width and 5 feet in length, this tape is a versatile solution for home repairs, DIY projects, and even emergency situations.

Are there different types of control boxes? Pump control boxes can really be separated into three (3) different types, Quick Disconnect (QD), Standard, and Deluxe. The QD boxes are designed for smaller horsepower motors and generally include 1/2hp, 3/4hp, and 1hp applications. Standard control boxes cover 1hp-10hp while Deluxe boxes cover 2hp-15hp. The Deluxe boxes have the addition of a line contactor which allow for an alternate wiring configuration of the pressure switch. Check out our videos on pressure switches and control boxes for more information on this topic. Another notable difference between the QD box and the Standard/Deluxe boxes are the presence of overload protection in the Standard/Deluxe boxes.

Applications of Butyl Rubber Tape

Hydraulic Control Boxes

So, while you probably don’t have to worry about your electrical tape catching fire spontaneously, you should still be careful with it around open flames.

Insulating tape, also known as electrical tape, is a commonly used tool for insulating and protecting electrical wires and cables. It is typically made of PVC material and has a pressure-sensitive adhesive on one side that allows it to adhere to various surfaces.

In conclusion, an automotive wiring loom wrap is an essential component in any vehicle, as it plays a critical role in protecting and organizing the complex network of wires that power the vehicle's electrical systems. By choosing the right type of wiring loom wrap and properly installing it, vehicle owners can help to prevent costly repairs and ensure the safety and reliability of their vehicles.

Electricians have critical jobs. Keeping our world powered requires concentration, knowledge and skill. Some of the most dangerous work is done by electricians working on medium and high voltage applications. Ethylene propylene and silicone rubber electrical tapes have the highest dielectric rating of electrical tapes made by 3M and are a trusted product in the toolbox of most medium and high voltage linemen and installers. With proper wrapping, their self-fusing properties help to eliminate voids in critical areas that may cause catastrophic failures .

In the realm of home repairs and DIY projects, having the right tools and materials at your disposal can make all the difference. One product that has gained significant popularity for its versatility and reliability is Flex Seal Flex Tape. Among its various sizes, the Flex Tape Black 4 x 5 version stands out for its utility in addressing a myriad of household needs.

In addition to its insulating properties, white PVC insulation tape is also used for color-coding wires. Electricians and technicians often utilize different colors of tape to mark various systems or functions, making troubleshooting and maintenance simpler. The white tape serves as an effective identifier, often used to signify neutral wires or other specific applications.

20mm intumescent strip. These strips are usually supplied in rolls or pre-cut lengths, making them easy to transport and handle on site. They can be quickly installed with adhesive or screws, and can easily be replaced if damaged or worn over time.