- The price list for lithopone pigment in China is influenced by several factors. Firstly, the availability and cost of raw materials, zinc sulfide and barium sulfate, have a direct impact on the final product pricing. Fluctuations in the global market for these minerals can lead to changes in the lithopone pigment prices. Secondly, production capacity and efficiency of Chinese manufacturers also play a crucial role. A high production capacity often results in more competitive pricing due to economies of scale.

- Furthermore, investing in research and development to explore safer alternatives, such as coated TiO2 particles to reduce dust generation, can be a proactive approach towards enhancing safety in the industry.

- Apart from its use in pigments and additives, titanium dioxide is also employed in the production of other chemicals

Le lithopone est produit par coprécipitation de sulfure de baryum et de sulfate de zinc, le plus souvent en proportions équimolaires, puis grillage de la pulpe résultante4.

- In conclusion, Anatase Titanium Dioxide plays a significant role in the food industry due to its unique properties as a coloring agent, anti-caking agent, and for preserving the original taste of food products. Its safety profile makes it a reliable choice for manufacturers looking to enhance the appearance and shelf life of their products while ensuring they are safe for consumption. As technology advances and consumer preferences evolve, the use of food-grade titanium dioxide is likely to continue being an integral part of food processing and presentation.

Furthermore, the use of titanium dioxide in rubber helps to reduce the environmental impact of rubber manufacturing processes. As a non-toxic and environmentally friendly material, titanium dioxide is safe for use in rubber products that come into contact with food, water, or other sensitive materials. This makes it an attractive choice for manufacturers looking to produce eco-friendly and sustainable rubber goods.

- In conclusion, identifying the best pigment rutile titanium dioxide manufacturers involves recognizing those who combine technological prowess, product excellence, sustainability efforts, and customer-centric approaches. As the industry evolves, so too does the quest for titanium dioxide perfection, driven by the relentless pursuit of manufacturers dedicated to setting new standards in pigment technology.

- However, challenges remain for China's talc and titanium dioxide industry. Environmental concerns surrounding the mining and processing of these minerals have led to increased scrutiny from both domestic and international regulators. Additionally, competition from other countries with abundant reserves of these minerals could potentially limit China's market share in the future. Despite these challenges, China's role in the global talc and titanium dioxide market is expected to remain significant, as the country continues to invest in its mining infrastructure and explore new applications for these versatile minerals.

- Furthermore, wholesale titanium dioxide 298 is known for its exceptional stability and durability. It is resistant to UV rays, chemicals, and weather conditions, making it a reliable choice for outdoor applications. This durability ensures that products maintain their color and appearance over time, saving manufacturers and consumers from frequent maintenance and replacement costs.

- The Significance of Anatase TiO2 Quotes from Leading Factories

- The global network of 1317-80-2% manufacturers is a testament to the interconnectedness of the modern world. They collaborate with suppliers, distributors, researchers, and end-users worldwide, forming a complex web of partnerships that facilitate knowledge exchange, technology transfer, and market access. This collaboration fosters innovation and drives the continuous improvement of the 1317-80-2% compound.

- What are the capital costs for setting up a lithopone manufacturing plant?

Still, you may wonder whether it’s safe for consumption.

The additive goes into a lot of personal care products to whiten and brighten colors and to make them opaque, like toothpaste and makeup.

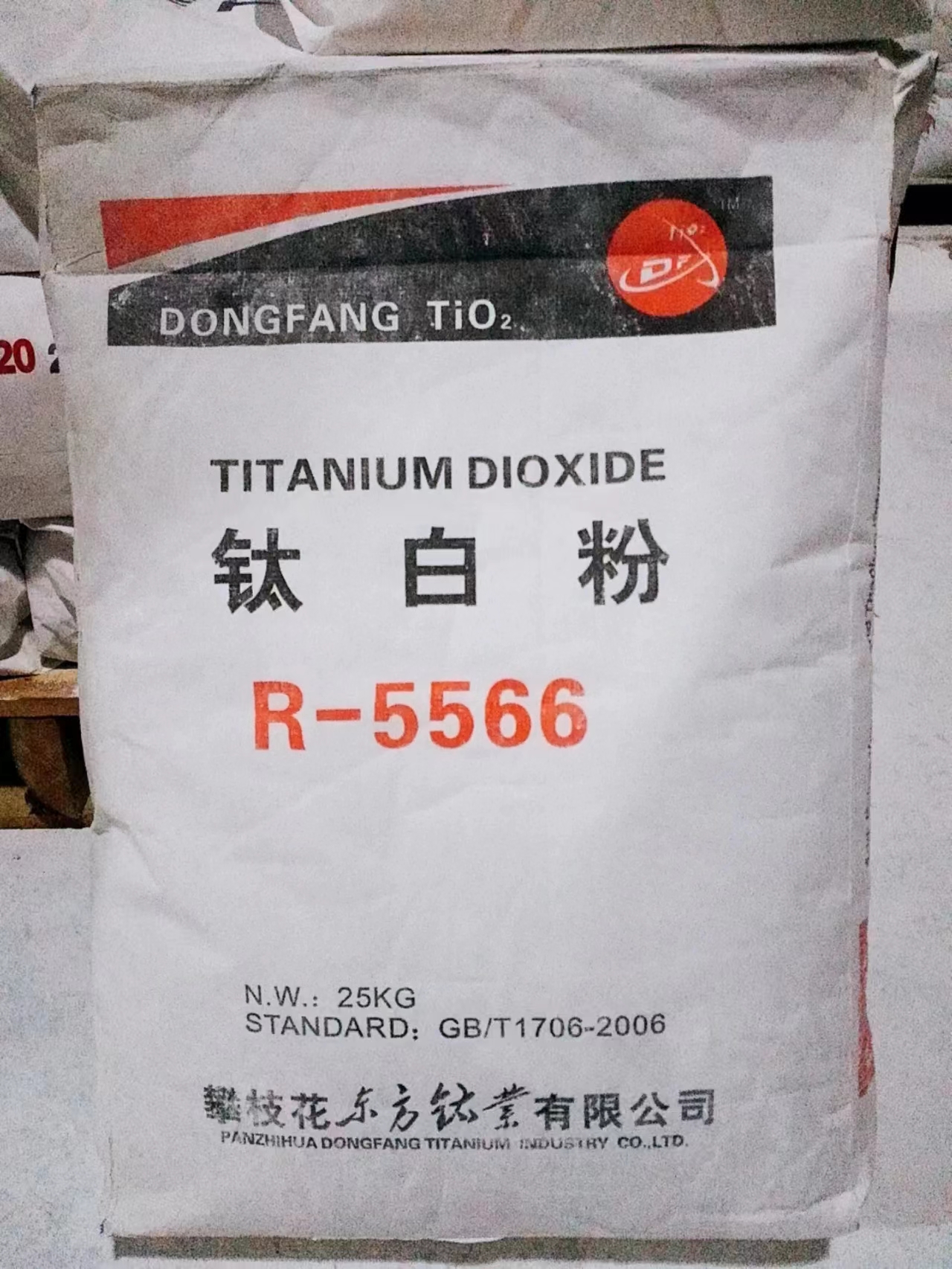

Application of Titanium Dioxide

Furthermore, Lomon's R996 grade titanium dioxide is manufactured using advanced production techniques to ensure consistency and quality in every batch. The company's state-of-the-art facilities and rigorous quality control measures guarantee that customers receive a reliable and high-performing product every time.

Histoire

How Is Titanium Dioxide Made?

Does not work with hydrogen sulfide and alkaline solutions. It is easy to decompose in the presence of acid to produce hydrogen sulfide gas. It is easily oxidized in the air and deteriorates after moisture. Whiteness and hiding power are strong.

Historically, the first mentions of zinc sulfide being utilized as a pigment were approximately sixty years before the everyday use of lithopone. Originally, it was thought to be appropriate for coloring rubber. In England, a patent was granted for this process. Two decades after this, the focus shifted to zinc sulfide as a suitable pigment for paint. The year 1874 witnessed the patenting of a manufacturing process for a novel white pigment composed of zinc sulfide and barium sulfate. Dubbed Charlton white or Orr’s white enamel, this began a new era for white pigments.

A legal additive in the United States, titanium dioxide is used in everything from food to consumer goods and the U.S. Food and Drug Administration says regulated use of the product as a color additive in food is safe within certain restrictions.

EFSA Scientific Conclusion on E171

A steep decline in the prices of titanium dioxide was observed in the second half of 2022 as the erratic energy costs along with rising covid cases affected the market negatively. In addition to this, the decreased offtakes from paints and coating industries, weak economic growth, and strict restrictions imposed to deal with the resurgence of covid cases further aided the declining trajectory of titanium butoxide prices.