In 1845, a surgeon named Dr. Horace Day made the first crude surgical tape by combining India rubber, pine gum, turpentine, litharge (a yellow lead oxide), and turpentine extract of cayenne pepper and applying that mixture to strips of fabric. It was the first “rubber-based” adhesive and Dr. Day used it in his practice as a surgical plaster. Larger scale manufacturing of similar medical tapes began in 1874 by Robert Wood Johnson and George Seaburg in East Orange, NJ. That company would soon become the Johnson & Johnson Company we know today. Later in 1921, Earle Dickson who bought cotton for Johnson & Johnson noticed that the surgical tape kept falling off his wife Josephine’s fingers after cutting them in the kitchen. He fixed a piece of gauze to some cloth backed tape and the first Band-Aid ® was invented. It took almost 75 years from Dr. Day’s first crude tape until the early 1920’s when the first industrial tape application appeared. The application was electrical tape (although the adhesive was more of a cohesive film than the electrical tape we know today) to prevent wires from shorting. The second major industrial tape application was a result of the rise of the American automobile in the 1920’s. Two-toned automobiles were becoming popular and automakers needed a way to produce clean, sharp paint lines while using the new automatic paint spray gun. They started using the surgical tape that was available but the paint wicked through the cloth backing and caused defective paint jobs. Richard Drew, an engineer at Minnesota Mining and Manufacturing (3M) happened to be at a local body shop testing their WetorDry® brand sandpaper in 1925 and he saw the workers struggling to get clean paint lines. He went back to his lab and created a 2-inch wide crimp backed paper tape that became the first “masking tape” for painting. Jumping ahead to 1942 and World War II, Johnson & Johnson developed duct tape to seal canisters and repair equipment for the military. The tape was a basically a polyethylene coated cloth tape with good “quick stick” properties that made it easy to use in the field for emergency repairs. The world never looked back and duct tape can be found in almost any home or toolbox.

Why is Butyl Sealant Tape Used?

Whether you’re an electrician or are just working on a job site, it’s important to know the differences between different types of tape. Electrical tape is best suited for electrical insulation and securing electrical connections, ensuring safety when dealing with electrical components. On the other hand, duct tape thrives in its versatility and strength, making it an excellent choice for general repairs. As always, we recommend testing tape before use, and adhering to all manufacturer guidelines. Explore Surface Shield’s full line of tape options.

3M also makes an electrical tape made of silicone rubber for applications where Class “H” (180°C/356°F) temperatures are encountered i.e., silicone rubber cables.

Silicone self-adhesive tape is ideal for fixing leaky pipes and plumbing connections. Its water-resistant properties make it an excellent choice for creating a quick, temporary fix until proper repairs can be made.

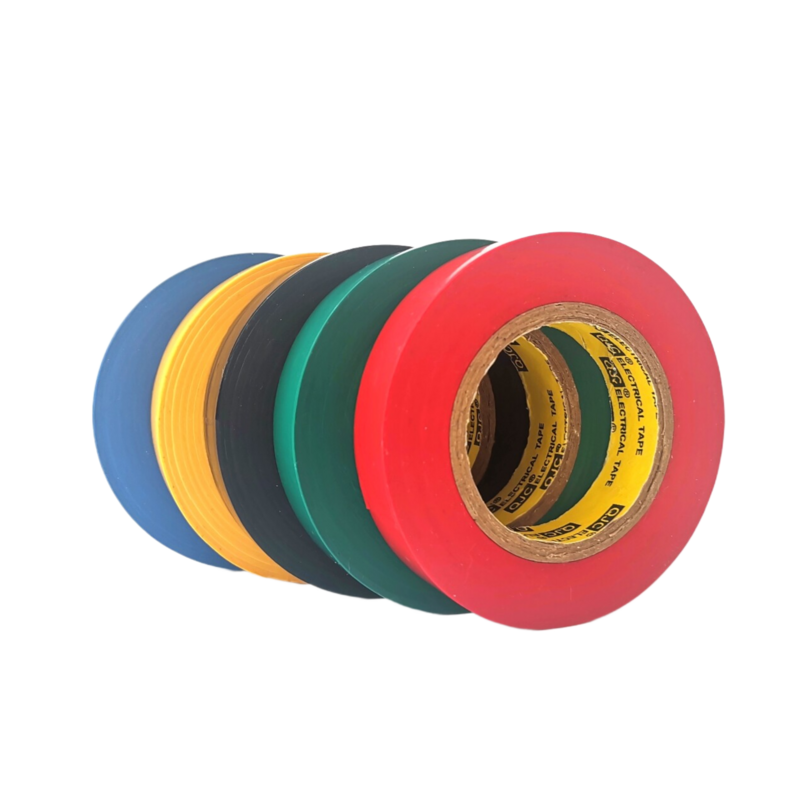

The 19mm width of the tape provides enough space for clear and visible color-coding The 19mm width of the tape provides enough space for clear and visible color-coding

The 19mm width of the tape provides enough space for clear and visible color-coding The 19mm width of the tape provides enough space for clear and visible color-coding pvc tape 19mm.

pvc tape 19mm.In today's world of DIY projects, home repairs, and industrial applications, self-fusing rubber tape has emerged as a vital tool due to its unique properties and versatility. This innovative tape has gained attention for its ability to create strong, long-lasting bonds without the need for adhesives, making it a go-to solution for various applications.

Electrical tape is designed to provide a secure bond but is easily removable and residue free. Duct tape is exceptionally sticky due to its adhesive composition. The rubber-based adhesive allows duct tape to bond with various surfaces for long periods of time. Because of its extreme stickiness, residue sometimes is left behind.

In electrical applications, white PVC insulation tape is often used for insulating wires and cables. It helps to prevent electrical shorts and protects against moisture, which can lead to corrosion and system failure. Whether encasing a repair or bundling multiple wires together, this tape ensures that connections remain safe and operational.

white pvc insulation tape

Rubber tapes repel moisture and are a great solution for outdoor applications or in manholes where water may occasionally seep in.

Whether it's repairing leaks in roofs, plumbing systems, or even automotive applications, this tape can be swiftly wrapped around the affected area, instantly creating a watertight seal Whether it's repairing leaks in roofs, plumbing systems, or even automotive applications, this tape can be swiftly wrapped around the affected area, instantly creating a watertight seal

Whether it's repairing leaks in roofs, plumbing systems, or even automotive applications, this tape can be swiftly wrapped around the affected area, instantly creating a watertight seal Whether it's repairing leaks in roofs, plumbing systems, or even automotive applications, this tape can be swiftly wrapped around the affected area, instantly creating a watertight seal premium leakage repair waterproof sealant butyl rubber tape.

premium leakage repair waterproof sealant butyl rubber tape.Composition and Properties

This can help to protect your family from potential health risks and prevent damage to your property This can help to protect your family from potential health risks and prevent damage to your property

This can help to protect your family from potential health risks and prevent damage to your property This can help to protect your family from potential health risks and prevent damage to your property door seal foam strip.

door seal foam strip.Tape thickness is usually measured in the United States in “mils”, or thousandths of an inch (1/1000”). The thickness can be measured from the bottom of the adhesive surface to the top of the outer surface or simply the film itself. In most cases, the thicker the tape the stronger and more durable it is. This is referred to as tensile strength. Thinner tape tends to be used for lightweight or temporary applications whereas thicker material is required for sealing heavy boxes and other heavy-duty applications. Duct tape is a great example of a thick adhesive roll whereas painting tape is often very thin and hand tearable.