Popular Applications

What is a Walking Foot Sewing Machine?

1. Increased Efficiency Automation reduces the time it takes to seal bags, allowing for faster production rates and minimizing labor costs. In high-demand settings, this can be a game changer for meeting tight deadlines.

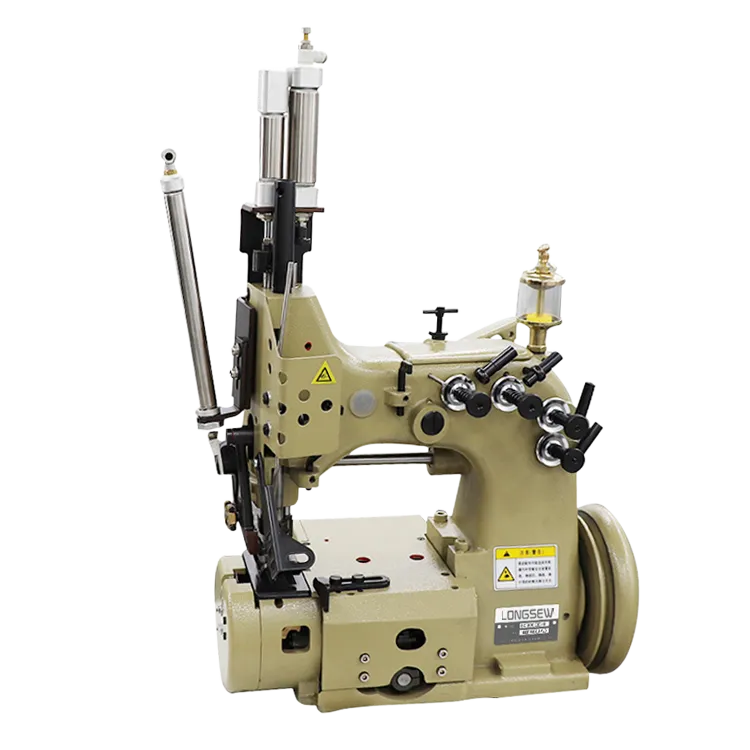

plastic bag closer machine

Fortunately, many manufacturers provide comprehensive manuals and online resources to assist users in becoming proficient. Engaging in online forums or communities can also offer valuable insights and tips from experienced stitchers.

4. Versatility in Craft Projects While specifically designed for upholstery, long needles can be incredibly versatile and useful in various sewing projects, including quilting and crafting. Their design allows them to be effective in numerous applications, making them a valuable addition to any sewing toolkit.

Another aspect to consider when looking at the price of the Durby Zig Zag Sewing Machine is the available accessories and support. Many retailers bundle extra presser feet, instructional manuals, and online resources with the purchase, enhancing the overall package. Such inclusions can significantly increase the value, making the initial investment more appealing.

Leather is a robust and durable material, and it requires special handling compared to standard fabrics. Its thickness, texture, and weight can vary significantly, which means that not all sewing machines can handle it efficiently. Leather often features a natural grain that not only adds to its aesthetic appeal but also presents challenges when sewing, such as the risk of slipping or uneven seams. Therefore, selecting a sewing machine specifically designed for leather is crucial.

1. Practice on Scrap Fabric Start with practice pieces before working on the final project. This approach allows one to get comfortable with the needle and thread, honing the technique without the pressure of a completed piece.

Quality is a key concern for any textile manufacturer. Overlock sewing machines contribute to higher quality outputs by creating durable seams that withstand stress and movement. The overlocking stitch is inherently stronger and more flexible than a standard straight stitch, making it ideal for garments that require stretch, such as athletic wear or fitted clothing. This ensures that the end products do not only look good but also last longer, reducing return rates and improving customer satisfaction.

4. Reduced Friction The chrome finish minimizes friction, resulting in less heat build-up during sewing. This is particularly advantageous when working on long sewing projects, as it helps prevent needle breakage and stitching issues.

Beyond fashion, the double needle lockstitch machine is also extensively used in upholstery, automotive seating, and leather goods production. These industries demand stitching that can withstand wear and tear while maintaining an aesthetically pleasing appearance. The versatility of the double needle lockstitch machine enables it to meet these stringent requirements effectively.

Maintenance and Care

When sewing leather and vinyl, the sewing machine must operate effectively with thick materials. Unlike standard fabrics, leather and vinyl do not fray easily, and they require a different approach in terms of needle size, thread type, and sewing speed. Additionally, when choosing a sewing machine for these materials, it is crucial to consider the presence of walking feet, heavy-duty construction, and the ability to handle thick layers without jamming.

In conclusion, the floating foot sewing machine has redefined the sewing landscape by providing enhanced precision, flexibility, and user-friendly features. Whether you are a budding enthusiast or a seasoned professional, integrating this innovative sewing tool into your crafting toolkit can significantly elevate your sewing experience. As technology continues to evolve, it’s exciting to foresee what other advancements will shape the future of sewing, but for now, the floating foot machine stands out as a definitive asset in the world of textiles. Embracing this technology not only streamlines the sewing process but also opens up endless possibilities for creativity and craftsmanship in every stitch.

What is a Lockstitch Sewing Machine?

One of the primary features of a needle feed sewing machine is its enhanced fabric handling capability. The machine’s needle feed mechanism allows it to handle a wide range of materials, from lightweight fabrics like silk to heavier materials like denim and canvas. This versatility makes it an ideal choice for a variety of sewing applications, including garment manufacturing, upholstery, and leatherwork.

Lock stitches are used in numerous sewing applications, from garment construction to quilting, due to their structural integrity

. Here are some common useslock stitch on sewing machine