Once you reach the timing belt, rotate the crankshaft to align the timing marks on the crankshaft and camshaft pulleys. This step is crucial for maintaining engine synchronization.

3. Practice on Samples If you are new to this type of stitching, practice on fabric scraps. This will help you familiarize yourself with the machine's operation and the intricacies of the stitch.

In recent years, the sewing industry has witnessed a significant surge in interest, particularly concerning serger machines. These specialized sewing machines have become a popular choice among both hobbyists and professional tailors, thanks to their ability to efficiently create clean and durable seams. As the demand for serger machines continues to grow, both manufacturers and retailers are responding with attractive sales and promotions.

The Versatility and Utility of the 2% Needle Walking Foot Sewing Machine

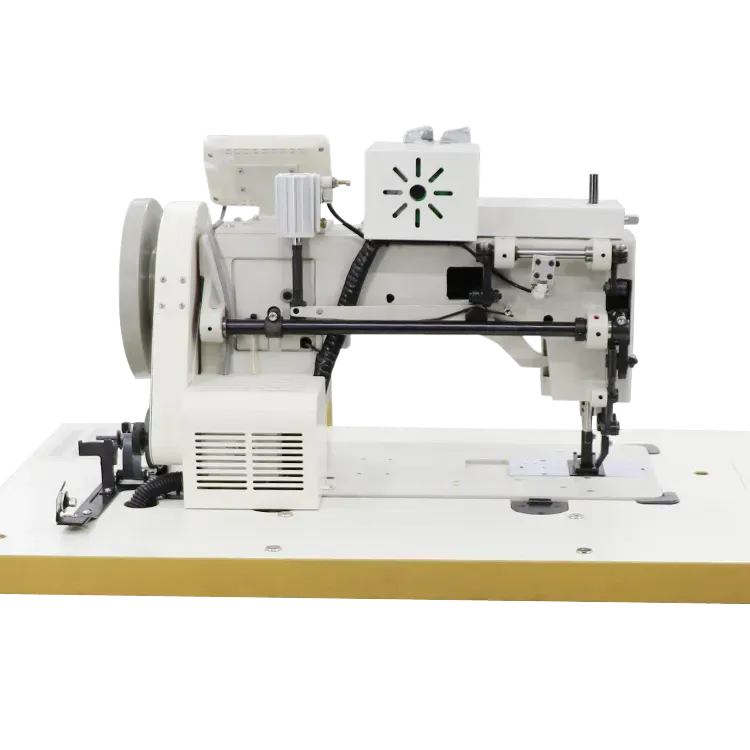

One of the standout features of industrial sewing machines used for upholstery is their ability to perform heavy-duty stitching. Unlike standard domestic sewing machines, these industrial models are equipped with powerful motors and reinforced components that can handle the rigorous demands of an upholstery workshop. This capability not only increases productivity but also significantly reduces the time required to complete upholstery projects, enabling manufacturers to meet tight production schedules without compromising quality.

industrial sewing machine for auto upholstery

Serger machines offer a range of stitching options that traditional sewing machines do not. Beyond basic overlocking, users can create rolled hems, which are particularly useful for lightweight fabrics, and flatlock stitches, which are great for joining seams. Many sergers also have the capability to perform coverstitching, which is often used in the hems of T-shirts and activewear. This versatility allows sewists to tackle various projects, from simple alterations to complex garments.

Benefits of Using a Hand Crank Sewing Machine

In conclusion, CNC programmable sewing machines are revolutionizing the textile and garment industry by providing unmatched precision, efficiency, and adaptability. As manufacturers continue to seek innovative ways to improve production processes while meeting consumer demands for sustainable and unique products, these advanced machines are likely to play an increasingly pivotal role. The marriage of technology and craftsmanship in sewing not only enhances productivity but also paves the way for a more sustainable and capable future in fashion manufacturing.

Key Features of Industrial Zig Zag Embroidery Machines

1. Versatility Long arm and high arm zigzag sewing machines are designed to handle a wide range of sewing tasks, from quilting to garment making. The zigzag stitch feature allows sewists to experiment with different techniques, patterns, and fabrics.

A walking foot leather sewing machine is an invaluable tool for anyone serious about leather crafting. With its ability to handle thick and slippery materials efficiently, it opens up a world of creative possibilities. Whether you're a seasoned leatherworker or just starting out, investing in a walking foot sewing machine could elevate your crafting experience, helping you produce beautiful and professional-quality leather goods with ease and precision. As the demand for unique leather products continues to grow, having the right tools will enable you to meet that demand while enjoying the process of creation.

Heavy-duty sewing machines are specifically designed to handle thicker fabrics and multiple layers, which are common in projects like upholstery, denim, and heavy quilting. Unlike standard sewing machines, heavy-duty models are equipped with powerful motors that provide increased speed and strength, allowing users to sew through tougher materials with ease. This capability is particularly beneficial for those who frequently work on substantial projects without experiencing fabric jams or thread breaks.

5. Finishing Touches Once the quilting is complete, adding borders, binding, and labels can transform your quilt further, giving it a polished and finished look.

- Leather Goods Artisans crafting leather items, from bags to belts, benefit immensely from the reliable stitching provided by these machines.

Industrial Overlockers for Sale A Comprehensive Guide

3. Increased Efficiency Utilizing a double needle machine speeds up the sewing process. Since two lines of stitching can be applied simultaneously, the time taken to complete projects is significantly reduced, allowing artisans to take on more work and increase their productivity.

This wasn’t just an aesthetic choice, for me. It was an emotional one. My grandmother used a Singer back in the day. And we still have the machine, even. Talk about a link to your past.

When you are sewing, it is recommended to ensure you are working on a large surface. For example, when sewing large items such as beddings, upholstery, and curtains, you need a large surface. That is why you need to buy a heavy-duty sewing machine because it contains a large working area and throat size.

When you are sewing, it is recommended to ensure you are working on a large surface. For example, when sewing large items such as beddings, upholstery, and curtains, you need a large surface. That is why you need to buy a heavy-duty sewing machine because it contains a large working area and throat size.

Construction of Lockstitch Seam

Maintenance is another aspect to consider with overlockers. Regular cleaning and proper threading are essential to ensure optimal performance. Unlike standard sewing machines, overlockers require the use of specialized threads, and tension adjustments may be necessary to achieve the desired stitches. A well-maintained overlocker can last for many years and consistently produce high-quality results.

Once you have chosen your machine, it's time to get started! Familiarize yourself with the user manual, and practice on scrap fabric to hone your skills. Begin with simple projects like pillow covers, tote bags, or even quilts. As your confidence grows, you can tackle more complex designs and techniques.

One of the significant advantages of machine embroidery in quilting is the ability to customize designs. Many quilting machines come with built-in editing software, allowing users to resize, rotate, and combine different elements to create a unique pattern. This feature empowers quilters to personalize their projects, adding their touch and making each quilt a true reflection of their style.

Factors Affecting Price