- Floor Line Tape A Comprehensive Guide

- In addition to its visibility, yellow insulation tape also offers excellent electrical insulation properties. It is made from high-quality materials that are specifically designed to withstand high temperatures and withstand exposure to moisture and other environmental factors. This ensures that the tape remains effective for an extended period, providing reliable protection against electrical shorts and other hazards.

- When using heat resistant electrical tape, it is important to follow some basic guidelines to ensure proper installation and effectiveness. First and foremost, it is essential to clean the surface before applying the tape to ensure maximum adhesion. It is also important to wrap the tape tightly around the connection, making sure to overlap the layers for added protection.

- Top professional quality, low price

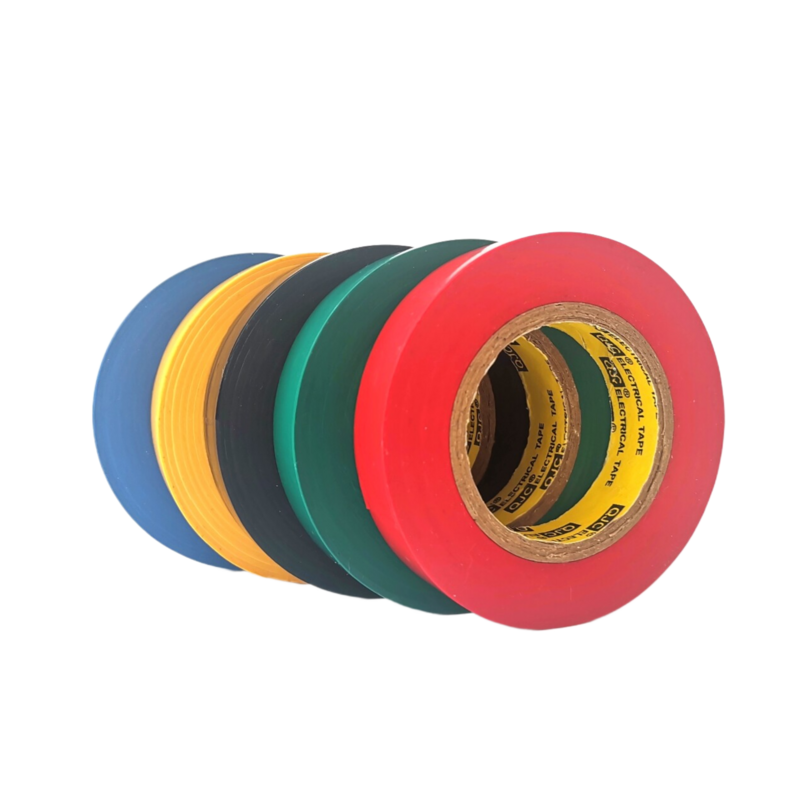

- Another benefit of PVC tape is its ability to provide effective insulation. When used to cover exposed wires or connections, the tape creates a barrier that prevents electricity from flowing where it shouldn't. This not only helps to prevent short circuits and other electrical issues but also ensures the safety of anyone working on or near the wires.

Natural rubber is a great option if you run a small business with a limited budget, PVC tapes with rubber adhesives are a good cost-effective choice. It is more durable than standard PolyPro tape, which makes it suitable for more heavy-duty packing. If you plan to ship heavy packages, you should stock some tapes with rubber adhesives so that you can guarantee the security of your packages.

Edge sealant in Solar PV

How Does It Work?

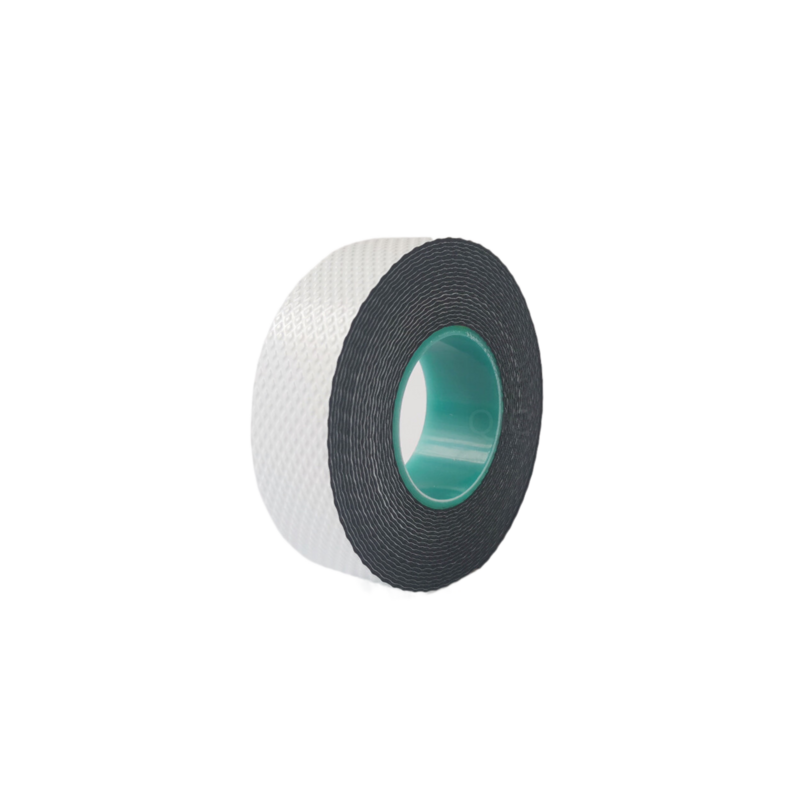

3M rubber tapes have operating temperatures ranging from 176°F (80°C) to 221°F (105°C). Some, Linerless Rubber Splicing Tape 130C and Rubber Splicing Tape 23, have overloads temperatures up to 266°F (130°C). Because of this high heat attribute; there are many industrial settings where it is common to use rubber tape in lower voltage applications to moisture seal, pad and insulate:

In addition to its insulation properties, yellow tape plays a pivotal role in safety and hazard marking. Many industries utilize colored tape to demarcate hazardous areas, warn of potential dangers, or designate specific zones. The color yellow is universally associated with caution, making yellow insulation tape an effective tool for alerting individuals to be wary of risks in their environment.

insulation tape yellow

In a typical tape splice, you’ll tug and pull out the tape, stretching it to just before the breaking point. The tape’s width narrows to about 1/3rd of its original size. The tape’s length increases; your hand travels very quickly up to 20” away from where you started. Quite often you’ll be wrapping in a tight location making this even more difficult. Proper taping techniques are critical to realizing the many performance benefits of rubber tape.

In electrical applications, white PVC insulation tape is often used for insulating wires and cables. It helps to prevent electrical shorts and protects against moisture, which can lead to corrosion and system failure. Whether encasing a repair or bundling multiple wires together, this tape ensures that connections remain safe and operational.

white pvc insulation tape

However, it is also essential to consider the limitations of Black Flex Tape. While it offers excellent short-term and mid-term solutions, it may not always be suitable for long-term structural repairs. In cases where heavy-duty strength and durability are required, additional methods or materials might still be necessary. Though it excels at providing temporary fixes, users should remain mindful of the contexts in which they are applying it.

When was silicone tape invented?

. Unlike more extensive renovations or replacements, this simple addition can be easily installed by homeowners without professional help, making it an accessible option for those looking to enhance their living conditions without breaking the bank.

. Unlike more extensive renovations or replacements, this simple addition can be easily installed by homeowners without professional help, making it an accessible option for those looking to enhance their living conditions without breaking the bank.3. Peel and stick.Butyl sealant tape usually comes with a protective backing to prevent it from sticking to itself during storage and handling. Carefully peel off the backing to expose the adhesive side of the tape. Position the adhesive side of the tape on the surface, and carefully align it with the area to be sealed.

brown insulation tape. It finds its utility in automotive repairs, plumbing, HVAC systems, and even in sports and fitness for securing athletic gear or providing support to muscles. Its ease of use, combined with its durability, makes it a go-to solution for quick fixes and preventive maintenance tasks.

brown insulation tape. It finds its utility in automotive repairs, plumbing, HVAC systems, and even in sports and fitness for securing athletic gear or providing support to muscles. Its ease of use, combined with its durability, makes it a go-to solution for quick fixes and preventive maintenance tasks.Overall, splicing tape is an indispensable tool in the film editing process. It allows editors to seamlessly combine different pieces of film to create a cohesive and coherent final product. Without splicing tape, the editing process would be much more cumbersome and time-consuming, leading to a less polished and professional end result.

Silicones have been used to formulate adhesive products for decades due to their flexibility, temperature cycling resistance, chemical resistance, and wide range of possible material properties.

This makes it ideal for outdoor applications where exposure to moisture, heat, or UV radiation is a concern This makes it ideal for outdoor applications where exposure to moisture, heat, or UV radiation is a concern

This makes it ideal for outdoor applications where exposure to moisture, heat, or UV radiation is a concern This makes it ideal for outdoor applications where exposure to moisture, heat, or UV radiation is a concern 11kv insulation tape. The tape is designed to maintain its performance and adhesion even in challenging conditions, ensuring long-term reliability and protection for the electrical components it is used to insulate.

11kv insulation tape. The tape is designed to maintain its performance and adhesion even in challenging conditions, ensuring long-term reliability and protection for the electrical components it is used to insulate.Applications