Having solar panels on your roof is also a way to raise awareness: it shows your neighbors that this green technology exists and is accessible.

As awareness of climate change grows, the adoption of solar energy solutions like the 360 watt solar panel becomes increasingly vital. By choosing solar energy, individuals and businesses can play an active role in reducing greenhouse gas emissions and promoting sustainability. The shift towards renewable energy sources is not just an environmental concern; it also represents a path toward energy resilience and economic stability.

Factors Affecting Solar Panel Size Choice

solar panels size for home

Improvements in Solar Panel Technology A Path Toward Sustainable Energy

1. Space Optimization One of the primary advantages of custom size solar panels is their ability to make the most out of available space. For instance, homeowners with unusual roof shapes or limited area can benefit significantly from panels that fit precisely into those spaces. This optimization means that every square foot can be utilized to its maximum potential, resulting in higher energy production.

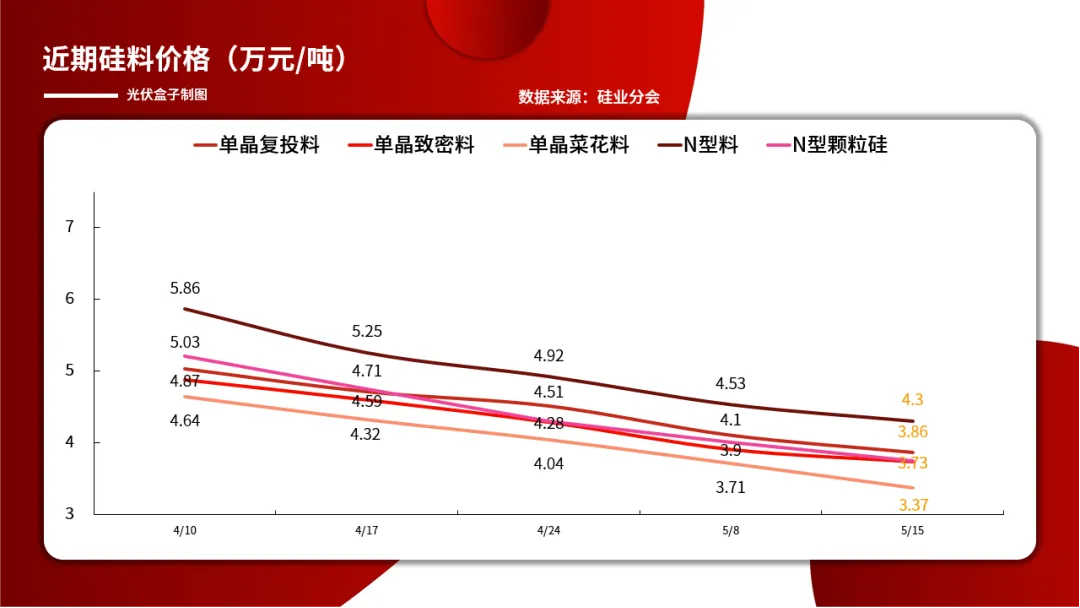

The decline in silicon prices also continues to affect the trend of silicon chip prices. According to the tracking data released by the Silicon Industry Branch on May 16, the lowest price in the silicon market this week has come to 12,000 RMB/ton, and the average price has plummeted by 20.4%.

When it comes to thickness, most solar panels are between 1.4 to 1.6 inches thick. However, with advancements in technology, more compact designs are being developed to enhance efficiency while minimizing space. The size and weight of solar panels also affect installation logistics, structural requirements, and transportation costs.

While the initial costs may seem high, a 250 kW solar panel system can lead to considerable long-term savings on electricity bills. Businesses can reduce their reliance on grid power, resulting in lower energy costs over time. Additionally, as energy prices continue to rise, locking in a fixed rate through solar can be financially advantageous.

In recent years, the global shift towards renewable energy sources has gained unprecedented momentum. At the forefront of this revolution is solar energy, a clean and sustainable option that has captured the interest of governments, businesses, and homeowners alike. Central to the functionality of solar power systems is the solar inverter, a critical component that enables the efficient conversion of solar energy into usable electricity. This article explores the significance of solar inverters, their operation, and their importance in promoting a sustainable energy future.

Planning Your Installation

Return on Investment

What is a Grid Tie Inverter?

High Cost of Solar Panels

A single-phase to three-phase converter is an electrical device that allows a single-phase power source to effectively operate three-phase devices. The converter takes the alternating current (AC) electrical power from a single-phase line and transforms it into three-phase power, enabling devices such as motors, machinery, and other industrial equipment designed to operate on three-phase systems to function correctly.

Advantages of String Inverters

In conclusion, solar wholesale is a critical component in the overall solar ecosystem, making renewable energy more accessible and affordable. By streamlining the purchasing process and ensuring the availability of high-quality products, wholesale suppliers play an essential role in accelerating the adoption of solar energy. As the world moves toward a more sustainable future, solar wholesale will continue to be an integral part of this journey, supporting both businesses and consumers in the transition to greener energy solutions.

What Are Solar Panels?

As we move towards a more sustainable future, medium-sized solar panels offer a practical and effective solution for harnessing solar energy. Their adaptability, affordability, and positive environmental impact present numerous opportunities for individuals and businesses alike to invest in renewable energy. By embracing medium-sized solar technology, we can contribute to a cleaner planet while also enjoying the myriad benefits that solar energy has to offer.

Yes, solar panels still generate electricity on cloudy days, although not as effectively as sunny days. Solar panels can capture both direct and indirect light (light that shines through clouds), but perform at around 10-25% of their normal efficiency when it’s cloudy.

Space availability also plays a significant role in determining how many panels can be installed. In urban areas where rooftop space is limited, homeowners may need to consider alternate solutions, such as ground-mounted systems or partnerships with solar farms. Therefore, understanding the physical dimensions of a 400-watt solar panel allows homeowners to visualize how they can utilize their space effectively while still maximizing energy production.