aisle marking tape. This not only saves time but also reduces the risk of errors and misplaced items.

Generally speaking, manufacturers use three different adhesive types in combination with the backing material to produce a final “tape” product. Though these adhesive types can be subdivided into subgroups, the main categories are as follows:

In plumbing repairs, amalgamating rubber tape is often used to fix leaks and reinforce pipe joints

. The tape can be applied to the damaged area and wrapped tightly to create a waterproof seal. Its flexibility and strength make it an ideal solution for emergency repairs or as a temporary fix until a permanent solution can be implemented.amalgamating rubber tape

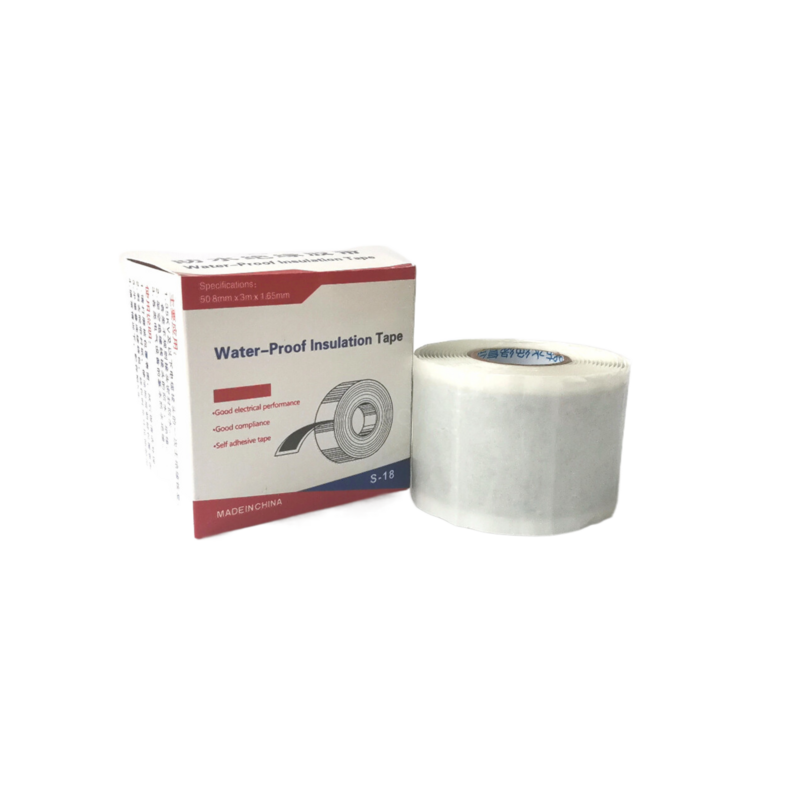

130c linerless rubber splicing tape. Whether used for electrical insulation, sealing, or bonding, the 130c% linerless rubber splicing tape provides a reliable and long-lasting solution.

The Versatility of Flex Tape A Comprehensive Review

Self-amalgamating tape is most commonly used to seal hoses, pipes and cables as well as to repair and protect them. It is particularly useful for protecting outdoor electrical joints in outdoor situations and, as mentioned above, it can protect sails from chafing in the marine industry. Plumbers will use self-amalgamating tape when fixing domestic leaks and car mechanics use it in radiator hose repairs. Closer to home, the tape is useful for adding more grip to sports equipment (racquets and bats), bicycle handles and much more!

Butyl rubber tape is a high-performance, waterproof adhesive tape made from butyl rubber, a synthetic rubber compound known for its excellent sealing properties. It possesses unique characteristics that make it an ideal choice for repair work, particularly in areas prone to water exposure. Unlike conventional tapes, butyl rubber tape is designed to remain flexible and durable, even under harsh weather conditions.

The use of electronic enclosures for control boxes isn’t limited to industrial applications. Outdoor consumer electronics are more popular than ever, with many homeowners installing large and complex lighting and entertainment systems that turn any patio into a movie theater or dance floor. Naturally, this raises the problem of designing electronics that stand up to the elements.

Electrical tape is used to protect against electrical shock and short circuits.

No special tools or skills are required – simply cut, apply, and press firmly for an instant fix No special tools or skills are required – simply cut, apply, and press firmly for an instant fix

No special tools or skills are required – simply cut, apply, and press firmly for an instant fix No special tools or skills are required – simply cut, apply, and press firmly for an instant fix flex seal tape blue. It's a DIYer's dream, offering a quick and convenient solution to emergencies, saving time and effort that would otherwise be spent on extensive repairs.

flex seal tape blue. It's a DIYer's dream, offering a quick and convenient solution to emergencies, saving time and effort that would otherwise be spent on extensive repairs.

Self-adhesive electrical tape also comes in a variety of colors, making it easy to color code your electrical wiring. This can help you quickly identify different circuits or connections, saving time and reducing the risk of errors.