variable speed v belt pulley

Flat top belts find applications in a wide range of industries. For instance, in the food and beverage sector, they are used to transport products through various stages of processing, packaging, and distribution. The smooth surface prevents contamination while ensuring that products remain secure.

Additionally, the quiet serpentine belt is often designed with a more refined surface texture. This helps reduce slip and friction, which not only lessens noise but also improves the belt's longevity and overall efficiency. The quieter operation of these belts can lead to less wear and tear on engine components, translating to savings in maintenance costs over time.

Functionality and Versatility

1. Cost-Effective By reducing wear and tear and minimizing maintenance efforts, these belts can lead to significant cost savings for businesses in the long run.

4. Automotive Applications While XL timing belts are not typically used in engines, they can be found in systems such as power windows, sunroofs, and other auxiliary systems that require synchronization.

- Squeaking or Squealing Noises If you hear unusual noises coming from the engine compartment, it may indicate a loose or worn-out belt. This is often a call for immediate inspection.

To ensure the longevity and optimal functioning of V-ribbed belt pulleys, regular maintenance is essential. Here are some maintenance tips

Understanding Sawtooth Conveyor Belts An Essential Element in Modern Manufacturing

1. Rubber Rubber belts are known for their excellent grip, flexibility, and durability. They are widely used in industries that require high friction and resilience.

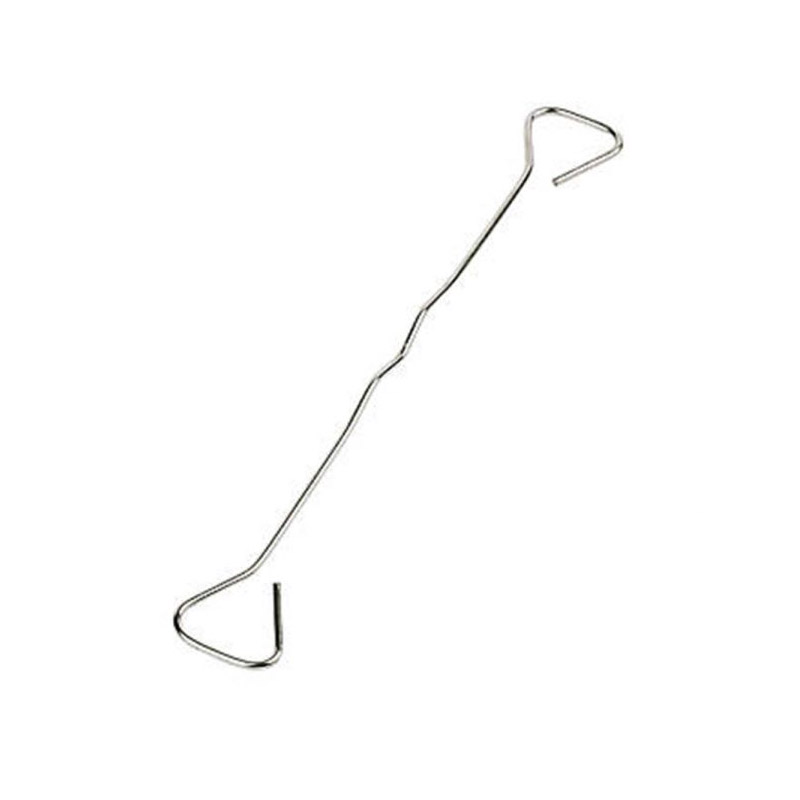

tension coil spring. Their compact size and ability to withstand varying loads make them ideal for confined spaces.

tension coil spring. Their compact size and ability to withstand varying loads make them ideal for confined spaces.

This can help construction projects save on time and labor costs, making it a practical choice for large-scale projects This can help construction projects save on time and labor costs, making it a practical choice for large-scale projects

This can help construction projects save on time and labor costs, making it a practical choice for large-scale projects This can help construction projects save on time and labor costs, making it a practical choice for large-scale projects concrete wire mesh chair support.

concrete wire mesh chair support. lowrider coil springs. Most coils are made from high-quality steel, which is strong and durable. However, some enthusiasts prefer to use chrome-plated steel or even titanium for a unique look and increased corrosion resistance.

lowrider coil springs. Most coils are made from high-quality steel, which is strong and durable. However, some enthusiasts prefer to use chrome-plated steel or even titanium for a unique look and increased corrosion resistance.Metal grid wall panels are a versatile and practical solution for organizing and displaying items in various environments. These panels are commonly found in retail stores, galleries, trade shows, and even home offices. With their grid-like design, they offer a convenient way to showcase products and make a statement in any space.