v belt pulley price

Maintenance Considerations

- Automotive In cars, belts are used for driving various accessories, including the alternator, water pump, and air conditioning compressor. Timing belts ensure proper engine timing, preventing catastrophic failures.

In the realm of automotive engineering, the timing belt is a crucial component that plays a significant role in the overall performance and longevity of an engine. Among the various types of timing belts, non-interference engine timing belts hold particular importance. Understanding their design, functionality, and advantages is essential for both automotive enthusiasts and everyday car owners.

2. Fabrication After extrusion, the V-belt is reinforced with layers of fabric and additional rubber. This step is crucial as it enhances the strength and longevity of the belt.

High-Quality Standard Transmission Belts Essential Components for Optimal Performance

Replacing the v-ribbed belt is often a straightforward process that can prevent more significant issues down the line, such as accessory failure or engine overheating. As a rule of thumb, it is advisable to follow the manufacturer's recommendations for replacement intervals, which typically range from 60,000 to 100,000 miles, depending on the vehicle model and driving conditions.

Motorcycle drive belts are critical components that contribute to the smooth and efficient power transfer required for a thrilling ride. Understanding their advantages and maintenance needs can help riders enjoy their motorcycles to the fullest while ensuring that these unsung heroes of motorcycling continue to perform at their best. Whether commuting through urban landscapes or embarking on long rides, appreciating the functionality of drive belts enhances the riding experience and offers peace of mind on every journey.

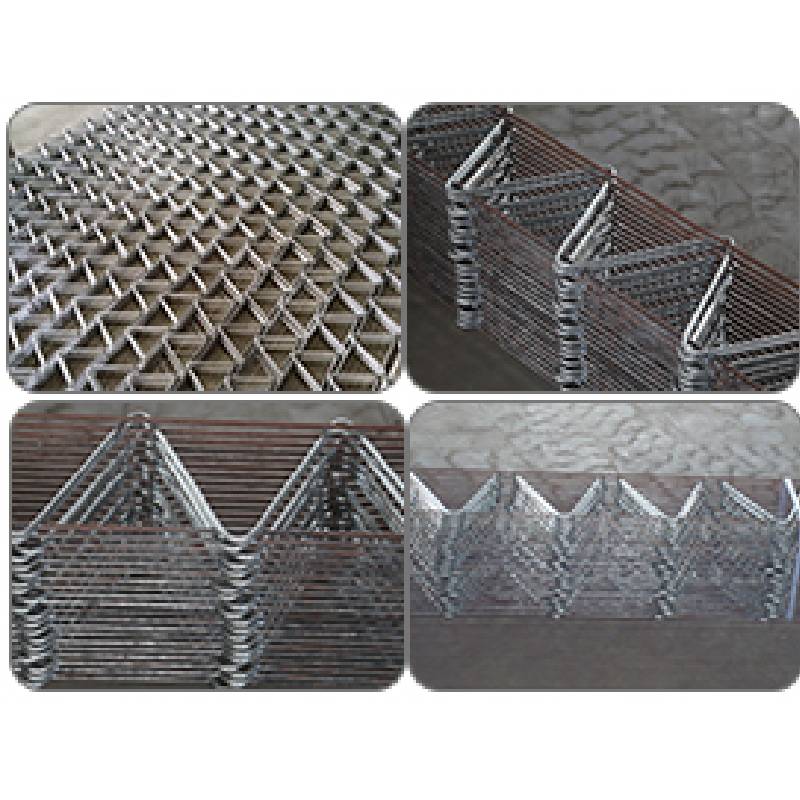

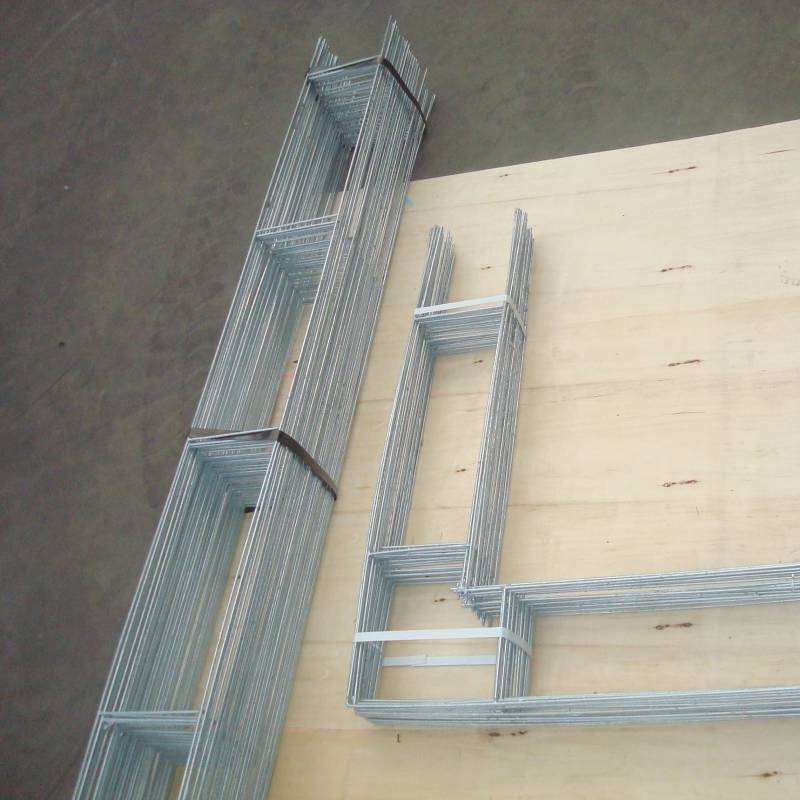

It ensures that the concrete assumes the desired dimensions and shape, while also preventing it from leaking or spilling out It ensures that the concrete assumes the desired dimensions and shape, while also preventing it from leaking or spilling out

It ensures that the concrete assumes the desired dimensions and shape, while also preventing it from leaking or spilling out It ensures that the concrete assumes the desired dimensions and shape, while also preventing it from leaking or spilling out

This modular approach aligns well with the principles of modern construction, which favor speed, consistency, and industrialization This modular approach aligns well with the principles of modern construction, which favor speed, consistency, and industrialization

This modular approach aligns well with the principles of modern construction, which favor speed, consistency, and industrialization This modular approach aligns well with the principles of modern construction, which favor speed, consistency, and industrialization

Standard rolls are usually 50 feet or 100 feet long and 50 inches wide, but custom sizes are available at varying prices Standard rolls are usually 50 feet or 100 feet long and 50 inches wide, but custom sizes are available at varying prices

Standard rolls are usually 50 feet or 100 feet long and 50 inches wide, but custom sizes are available at varying prices Standard rolls are usually 50 feet or 100 feet long and 50 inches wide, but custom sizes are available at varying prices

For many people, it represented strength, resilience, and the determination to protect what they valued most For many people, it represented strength, resilience, and the determination to protect what they valued most

For many people, it represented strength, resilience, and the determination to protect what they valued most For many people, it represented strength, resilience, and the determination to protect what they valued most