Whether you choose a handheld or heavy-duty sewing machine, it's essential to consider the availability of accessories and add-ons. These can enhance your sewing experience and provide added versatility.

Outerwear production involves making clothes like jackets, trench coats, parkas, and winter vests meant to be worn outside. These clothes are often made of more robust, durable materials to protect the wearer from the weather. A heavy-duty sewing machine is needed to make these clothes because it can handle thick or multiple layers and ensure the seams are strong and uniform.

Importance of Specialized Machinery

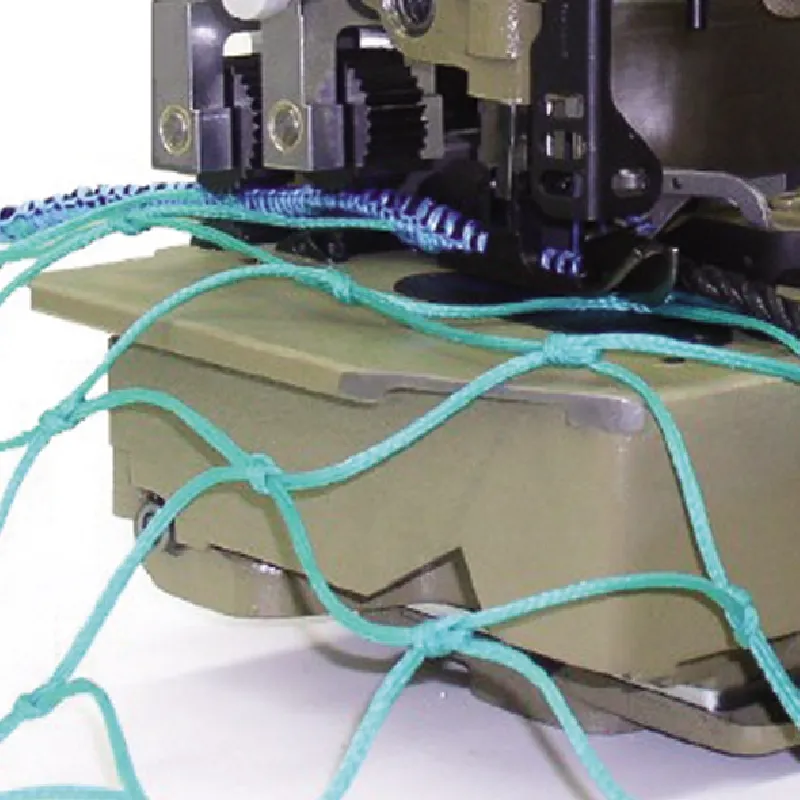

1. Efficient Handling of Thick Materials Upholstery fabric can be thick and tough. Long upholstery needles can handle multiple layers of dense materials such as canvas, leather, and foam padding. This capability is particularly useful when creating cushions or working on tufted furniture where multiple layers interlock.

The Double Needle A Seamstress's Secret Weapon

6. Durability and Build Quality Invest in a machine made from quality materials. Plastic machines may be lighter and easier to handle, but metal construction usually offers better durability.

- If you're on a tight budget, consider looking for a used sewing machine. Many people upgrade their machines and sell their old ones for a fraction of the price of a new machine. Just be sure to test the machine before purchasing to ensure it is in good working condition.

This wasn’t just an aesthetic choice, for me. It was an emotional one. My grandmother used a Singer back in the day. And we still have the machine, even. Talk about a link to your past.

Applications in the Sewing Industry

For those new to sewing or looking to streamline their process, the walking foot zigzag sewing machine offers ease of use. Setting up the machine with the walking foot is typically straightforward, and once in operation, it can significantly reduce the time spent on tedious tasks. The assurance that seams will be even and secure allows seamstresses to focus more on creativity and less on correction.

Final Thoughts

There are various types of industrial sewing machines tailored for leatherwork, including walking foot machines, post-bed machines, and cylinder-bed machines.

Applications in the Textile Industry

The Versatility of Coverstitch Chain Stitch in Garment Construction

2. Stitching Power For leather sewing, you need a machine capable of handling heavy materials. Look for machines with a robust motor and stitch length adjustment to accommodate different thicknesses of leather.

Versatility Across Industries

Moreover, ensuring the correct feed of the fabric is essential for producing even stitches. A poorly fed fabric can result in uneven seam allowances, which can affect the fit and finish of the garment or item being created.

4. Cost-Effectiveness By reducing the need for additional finishing processes, manufacturers can save on production costs, thereby increasing their overall efficiency and profitability.

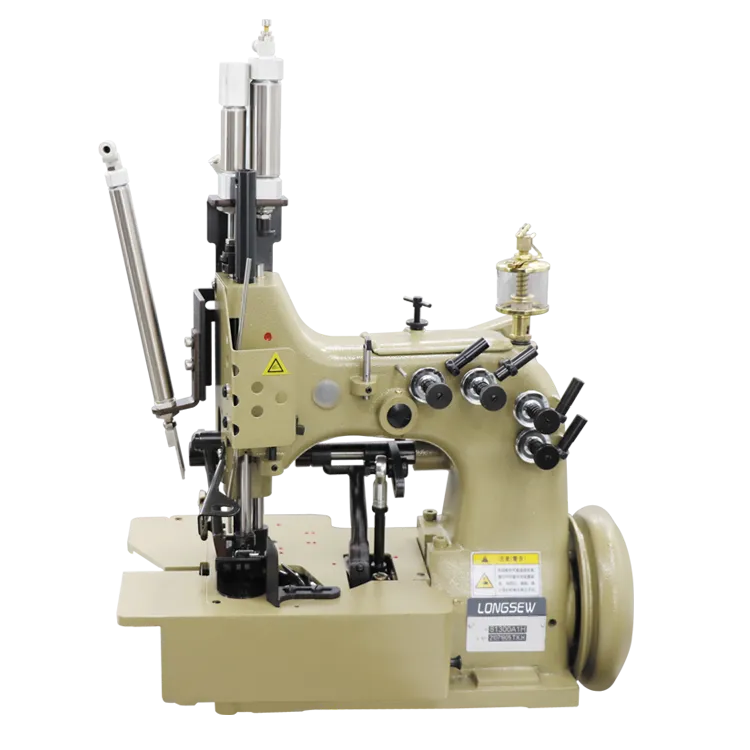

- One of the key features of a heavy-duty sewing machine is its powerful motor. Heavy-duty machines typically come equipped with motors that have higher wattage than regular sewing machines, which allows them to sew through thick fabrics and multiple layers with ease. This extra power also helps prevent the motor from overheating during long sewing sessions, ensuring smooth and consistent performance.