- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 11, 2025 19:54 Back to list

car v belt

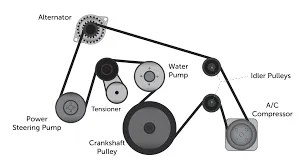

The automotive world continually evolves, introducing new components and refining old ones to enhance performance, efficiency, and reliability. Among these components, the V-belt occupies a significant position. Often recognized as the backbone of a vehicle's accessory drive system, understanding the V-belt's roles and features is crucial for car enthusiasts, mechanics, and drivers alike.

From an authoritative perspective, the V-belt's design and functionality have been a subject of research and development for decades. Industry leaders such as Gates Corporation and Dayco have pioneered innovations refining their performance parameters. These companies have conducted extensive testing to ensure that their belts meet the demands of various vehicle models and driving conditions. They provide comprehensive guidelines on diagnosing V-belt issues, installation procedures, and maintenance tips, which are pivotal for both professionals and car owners. For trustworthiness, one must consider regular maintenance checks. V-belts are known for their reliability, but like any component, they are susceptible to wear and tear. Signs of wear might include visible cracks, fraying edges, or glazing on the belt's surface. An unusual squealing noise when starting the engine or during gear shifts is often a telltale sign of a failing V-belt. It's advisable to route regular checks into vehicle maintenance schedules, perhaps every 60,000 to 90,000 miles, depending on the vehicle's make and model. Choosing a high-quality V-belt is imperative for ensuring performance and longevity. When selecting a replacement, always refer to the vehicle's manual or seek the expertise of a certified mechanic. Authentic belts designed specifically for your car model guarantee compatibility and optimal function. In conclusion, the V-belt might be a humble component within the vehicle's complex system, but its importance cannot be overstated. It enhances vehicle efficiency, ensures the seamless operation of essential car functions, and guarantees that devices like the alternator and power steering perform flawlessly. Understanding its significance and maintaining it diligently ensures that every drive is safe and smooth. Trust in established brands and adhere to maintenance checklists, and you'll ensure that your vehicle's V-belt serves its purpose without fail.

From an authoritative perspective, the V-belt's design and functionality have been a subject of research and development for decades. Industry leaders such as Gates Corporation and Dayco have pioneered innovations refining their performance parameters. These companies have conducted extensive testing to ensure that their belts meet the demands of various vehicle models and driving conditions. They provide comprehensive guidelines on diagnosing V-belt issues, installation procedures, and maintenance tips, which are pivotal for both professionals and car owners. For trustworthiness, one must consider regular maintenance checks. V-belts are known for their reliability, but like any component, they are susceptible to wear and tear. Signs of wear might include visible cracks, fraying edges, or glazing on the belt's surface. An unusual squealing noise when starting the engine or during gear shifts is often a telltale sign of a failing V-belt. It's advisable to route regular checks into vehicle maintenance schedules, perhaps every 60,000 to 90,000 miles, depending on the vehicle's make and model. Choosing a high-quality V-belt is imperative for ensuring performance and longevity. When selecting a replacement, always refer to the vehicle's manual or seek the expertise of a certified mechanic. Authentic belts designed specifically for your car model guarantee compatibility and optimal function. In conclusion, the V-belt might be a humble component within the vehicle's complex system, but its importance cannot be overstated. It enhances vehicle efficiency, ensures the seamless operation of essential car functions, and guarantees that devices like the alternator and power steering perform flawlessly. Understanding its significance and maintaining it diligently ensures that every drive is safe and smooth. Trust in established brands and adhere to maintenance checklists, and you'll ensure that your vehicle's V-belt serves its purpose without fail.

Share:

Next:

Latest news

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025