- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ડીસેમ્બર . 06, 2024 17:51 Back to list

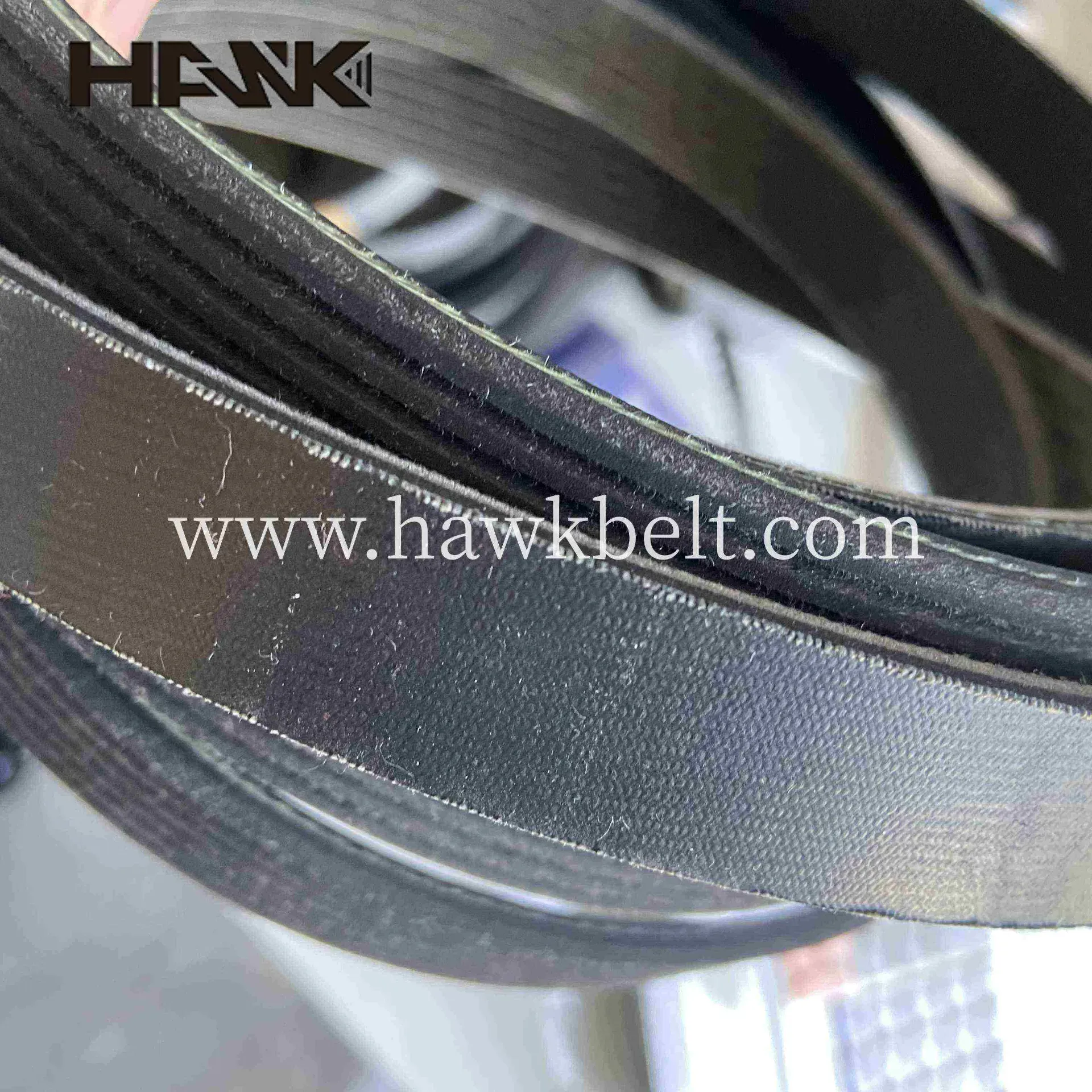

saw tooth conveyor belt

Understanding Sawtooth Conveyor Belts An Essential Element in Modern Manufacturing

In the realm of modern manufacturing and material handling, the sawtooth conveyor belt has emerged as a pivotal component, designed to enhance efficiency and productivity. The unique design and functionality of sawtooth conveyor belts make them suitable for various applications, particularly in industries where the movement of goods is paramount. In this article, we will explore the features, advantages, applications, and maintenance of sawtooth conveyor belts, shedding light on their significance in the manufacturing landscape.

What is a Sawtooth Conveyor Belt?

A sawtooth conveyor belt is characterized by its distinct sawtooth pattern, which often resembles a series of triangular projections along the belt's surface. This innovative design allows for better grip and stability when transporting goods, particularly those that are bulky or heavy. The sawtooth pattern helps to reduce slippage, ensuring a smoother and more reliable movement of products along the conveyor system.

Features of Sawtooth Conveyor Belts

1. Enhanced Traction The sawtooth design provides superior traction compared to standard flat conveyor belts. This is particularly beneficial for moving materials that may otherwise shift or slide during transportation.

2. Versatility Sawtooth conveyor belts are highly versatile and can be used in various industries, including food processing, packaging, mining, and automotive. They can accommodate a wide range of products, from lightweight items to heavy machinery parts.

3. Customizable These conveyor belts can be customized in terms of material, size, and configuration to meet specific application requirements. Whether it involves chemical resistance or temperature tolerance, manufacturers can tailor the belts accordingly.

4. Durability Made from robust materials, sawtooth conveyor belts are designed to withstand harsh operating conditions. This durability translates to a longer lifespan and reduced maintenance costs.

Advantages of Using Sawtooth Conveyor Belts

1. Increased Efficiency The improved grip and stability offered by sawtooth conveyor belts lead to a reduction in product loss and damage during transportation. This translates to increased efficiency in the manufacturing process.

saw tooth conveyor belt

2. Safety With reduced slippage and better stability, the risk of accidents in the workplace is minimized. Employees can work more confidently around conveyor systems, knowing that the products are less likely to fall or slide off.

3. Cost-Effective Despite their superior capabilities, sawtooth conveyor belts can be a cost-effective solution in the long run. Their durability and reduced maintenance requirements lead to lower overall operational costs.

4. Adaptability These belts can be integrated into various conveyor systems, whether they are inclined, declined, or horizontal setups. This adaptability makes them suitable for a diverse range of environments and industries.

Applications of Sawtooth Conveyor Belts

Sawtooth conveyor belts are widely utilized across different sectors. In the food processing industry, for instance, they greatly enhance the movement of packaged goods, allowing for efficient sorting and distribution. In manufacturing, they are often used to transport heavy parts along assembly lines, ensuring that products are moved safely and efficiently.

In the warehouse and logistics sector, sawtooth belts help streamline operations by facilitating the quick and safe movement of goods from one point to another. Their application extends to industries like pharmaceuticals, where precision and safety are of utmost importance.

Maintenance of Sawtooth Conveyor Belts

To ensure optimal performance, regular maintenance of sawtooth conveyor belts is crucial. This includes routine checks for wear and tear, ensuring proper alignment, and lubricating moving parts. Regular cleaning is also important to prevent the buildup of debris, which can affect traction and overall efficiency.

Conclusion

In conclusion, sawtooth conveyor belts play an essential role in modern manufacturing and logistics. Their unique design, coupled with numerous benefits, positions them as a preferred choice across various industries. As manufacturers continue to seek ways to improve efficiency and productivity, the importance of specialized equipment like sawtooth conveyor belts cannot be overstated. By understanding their features, advantages, and maintenance requirements, businesses can harness their full potential, paving the way for a more efficient future in material handling and production processes.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025