- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

નવેમ્બર . 08, 2024 20:30 Back to list

raw edge v belt

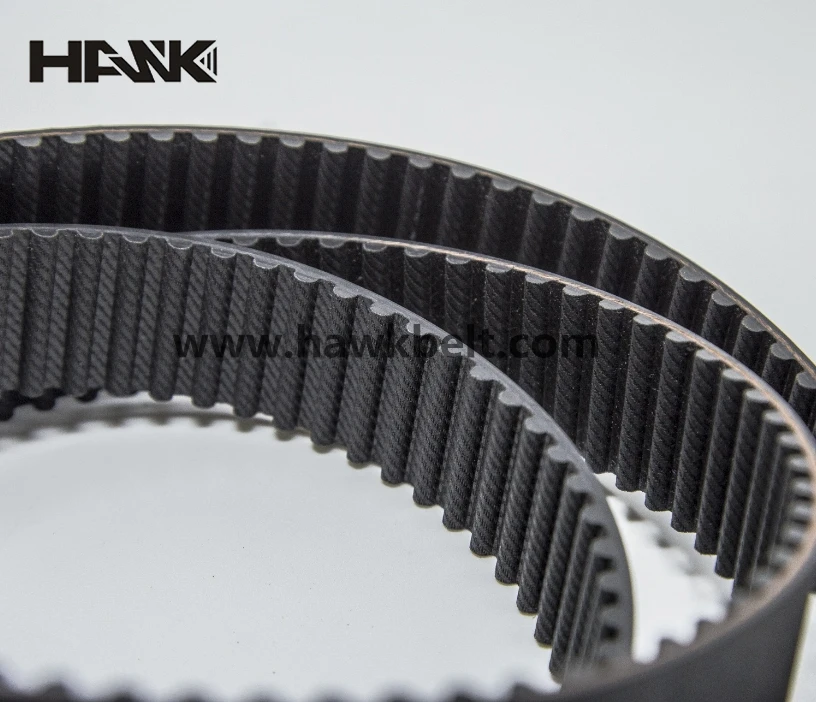

Understanding Raw Edge V Belts An In-Depth Exploration

Raw edge V belts have become an essential component in various mechanical systems, from industrial machinery to automotive applications. These belts are known for their unique design, which allows them to offer significant advantages over traditional V belts. In this article, we will delve into the characteristics, advantages, and applications of raw edge V belts, providing a comprehensive understanding of their role in power transmission systems.

What are Raw Edge V Belts?

Raw edge V belts, also known as raw edge cogged belts, are a type of power transmission belt that features a flat, uncured surface on the top side and a cogged or grooved profile on the underside. This design allows for improved flexibility and better grip on pulleys, resulting in more efficient power transfer. The absence of a fabric covering on the top side is what gives these belts their name – raw edge.

Unlike conventional V belts, which often have a smooth outer surface covered with a fabric, raw edge V belts provide direct contact with the pulleys, enhancing their ability to handle demanding conditions. They are primarily made from high-quality rubber compounds, which provide elasticity, strength, and resistance to wear.

Advantages of Raw Edge V Belts

1. Higher Power Transmission Efficiency One of the most significant advantages of raw edge V belts is their ability to transmit more power compared to standard V belts. The raw edge design increases the friction between the belt and the pulley, which results in improved grip and reduced slippage.

2. Improved Flexibility The cogged design allows for better bending capabilities, enabling raw edge V belts to navigate around smaller pulleys without compromising performance. This flexibility is particularly beneficial in applications with complex routing where space is limited.

3. Enhanced Heat Resistance Raw edge V belts can withstand higher temperatures due to their sturdy construction. This makes them suitable for applications that involve high-speed operations or those exposed to heat-generating environments.

4. Durability and Longevity The materials used in raw edge belts are resistant to wear and tearing, leading to a longer service life. This durability can result in reduced maintenance costs and fewer replacements over time.

raw edge v belt

5. Reduced Noise Levels The design of raw edge V belts also contributes to a quieter operation compared to traditional V belts. This characteristic is particularly advantageous in applications where noise reduction is essential, such as in office equipment and appliances.

Applications of Raw Edge V Belts

Raw edge V belts are used across various industries due to their versatility and performance benefits. Some common applications include

- Automotive Industry These belts are widely used in automotive engines for driving camshafts, water pumps, and air conditioning compressors. Their ability to handle high loads and perform efficiently under varying conditions makes them ideal for automotive applications.

- Industrial Machinery In manufacturing plants, raw edge V belts drive conveyors, fans, pumps, and compressors. Their robustness ensures that they can withstand the demands of heavy-duty machinery.

- Agricultural Equipment Equipment such as tractors and combine harvesters often utilize raw edge V belts for their high power transmission capabilities, ensuring efficient operation in the field.

- HVAC Systems The ability of raw edge V belts to operate quietly and efficiently makes them suitable for heating, ventilation, and air conditioning systems, where they drive fans and blowers.

Conclusion

Raw edge V belts represent a significant advancement in power transmission technology, combining unique design features with high performance. Their ability to transmit power efficiently, embrace flexibility, and resist wear makes them a preferred choice in various applications. As industries continue to evolve and demand more from their mechanical systems, raw edge V belts are poised to play a crucial role in enhancing operational efficiency and reliability. Understanding their benefits and applications can help businesses make informed decisions when selecting power transmission solutions.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025