- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

નવેમ્બર . 25, 2024 14:41 Back to list

engine belt drive

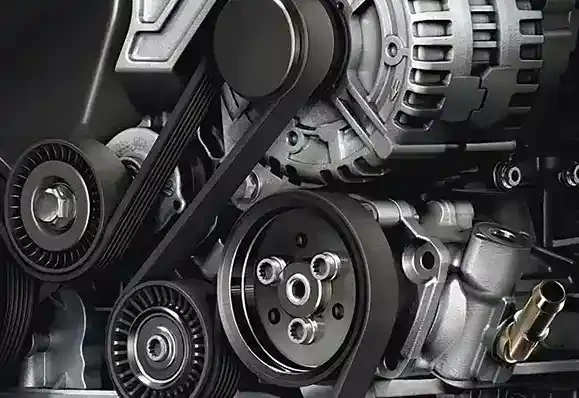

Understanding Engine Belt Drive Systems

The engine belt drive system is an essential component in various mechanical and automotive applications, ensuring efficient power transmission and optimal engine performance. This mechanism uses belts, which are flexible loops of material, to transfer motion and power between different parts of an engine, primarily from the crankshaft to other accessories or components.

Components of Belt Drive Systems

A typical engine belt drive system consists of several key components the engine crankshaft, pulleys, the drive belt itself, and accessories such as alternators, air conditioning compressors, and power steering pumps. The crankshaft, driven by the engine's pistons, serves as the primary source of mechanical power. Pulleys are attached to the crankshaft and the accessories, and they facilitate the seamless transfer of energy. The drive belt, which can be made from rubber or a composite material, wraps around these pulleys, allowing the power generated by the engine to be transmitted to the accessories efficiently.

Types of Belts

There are mainly two types of belts used in engine drive systems V-belts and serpentine belts. V-belts are named for their distinctive V shape, which provides a greater surface area for friction and helps to transmit power effectively. These belts typically drive a single accessory or a set of accessories. In contrast, serpentine belts are long, continuous belts that snake around multiple pulleys, allowing one belt to power several accessories at once. This design reduces weight, simplifies installation, and minimizes maintenance needs.

Advantages of Belt Drives

engine belt drive

Belt drive systems offer several advantages over other power transmission methods, such as chain drives or gear systems. One of the most significant benefits is their ability to reduce noise levels; belts operate more quietly than chains or gears, making for a more pleasant driving experience. Additionally, belt drives provide inherent shock absorption, which helps protect engine components from sudden changes in load, thus extending the life of the system.

Moreover, belt drives are generally lighter and more flexible, allowing them to fit in more compact engine spaces without compromising performance. They also require less lubrication than chain drives, which reduces maintenance efforts and costs. This characteristic makes belt drive systems particularly appealing in modern automotive design, where efficiency and performance are paramount.

Disadvantages and Maintenance

Despite their advantages, belt drives also have some drawbacks. Over time, belts can wear out, stretch, or crack, leading to reduced efficiency or potential failure. Regular inspection and maintenance are crucial to ensure that the system functions properly. Most manufacturers recommend replacing the drive belt at regular intervals, typically between 60,000 to 100,000 miles, depending on the vehicle and usage conditions.

Neglecting maintenance can lead to more severe issues, such as loss of power to critical engine components or complete belt failure, which may result in costly repairs and downtime. Thus, monitoring belt tension and condition is vital for both longevity and performance.

Conclusion

In conclusion, engine belt drive systems play a crucial role in the functionality of modern vehicles. Understanding their components, types, advantages, and maintenance requirements can aid in ensuring optimal performance and longevity. These systems are a perfect blend of efficiency, reliability, and adaptability, making them fundamental in today's automotive landscape. As technology continues to advance, we can expect further innovations in belt drive designs and materials, enhancing their effectiveness and reliability in various applications. Regular maintenance and awareness of their condition will ensure that these systems provide the necessary power transfer essential for modern automotive engines.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025