- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Set . 24, 2024 08:29 Back to list

Exploring the Benefits of Ribbed PK Belts for Enhanced Performance and Durability

Understanding PK Belt Ribbed An Insight into Ribbed Belts

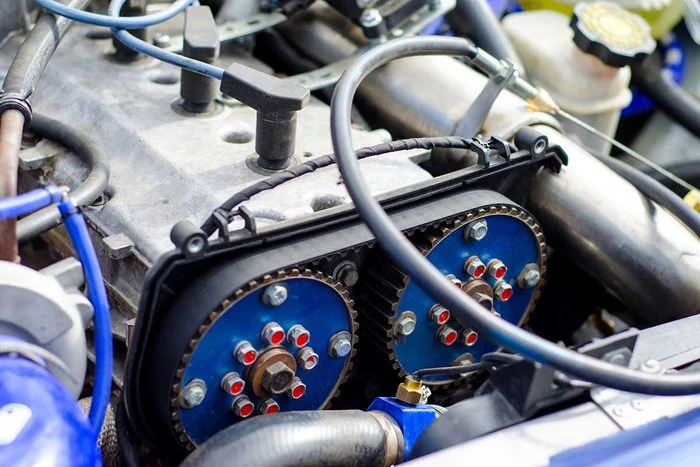

In the world of machinery and automotive components, the PK belt ribbed plays a critical role in ensuring both efficiency and performance. These belts, often referred to as ribbed or serpentine belts, are engineered to transmit power effectively between various engine components. They are an essential part of the engine’s operation, involved in driving accessories such as alternators, water pumps, power steering pumps, and air conditioning compressors.

Design and Characteristics

The design of the PK ribbed belt is distinctive, featuring a series of longitudinal ribs on its underside. This ribbed design enhances the belt's grip against the pulleys it interacts with. The ribs allow the belt to accommodate various pulley sizes while providing a larger surface area, which increases friction and reduces slippage. This is particularly important in high-performance vehicles where reliable power transmission is crucial.

PK belts are typically constructed from durable materials like EPDM (ethylene propylene diene monomer), which offers excellent resistance to heat, ozone, and abrasion. This ensures a longer lifespan, minimizing the frequency of replacements and subsequent maintenance costs. Additionally, the flexibility of the materials used allows these belts to bend around pulleys without losing strength, further accentuating their effectiveness in power transmission.

Applications

PK ribbed belts are commonly used in a wide range of applications. In automotive settings, they play a vital role in the operation of engine components, making them indispensable for vehicle functionality. Beyond the automotive industry, ribbed belts are also utilized in various machinery and industrial settings, driving equipment such as conveyor systems, pumps, and fans.

pk belt ribbed

Moreover, the versatility of PK belts means they can be found in household appliances too, such as washing machines and vacuum cleaners. Their ability to operate quietly while providing maximum power transmission makes them ideal for everyday usage.

Maintenance and Replacement

Maintaining the integrity of PK belts is important for the overall health of the engine or machinery they support. Regular inspections can help identify signs of wear, such as cracks, fraying, or glazing. It is advisable for vehicle owners to follow the manufacturer's recommendations regarding the replacement intervals for these belts. Failure to do so can lead to more significant issues, including engine overheating or failure of auxiliary components.

When replacing a ribbed belt, it is crucial to select the correct size and type for the specific application. Mismatched belts can lead to inefficiencies and mechanical failures. Automotive professionals often recommend consulting with a technician or referring to the vehicle's service manual to ensure an accurate replacement.

Conclusion

In summary, PK ribbed belts are an integral component in both vehicles and various machinery. Their design, characterized by ribs that enhance grip and efficiency, contributes significantly to their functionality. Understanding the importance of proper maintenance and timely replacement of PK belts can lead to improved performance and longevity of the machines they empower. As technology advances, the design and materials of these belts will continue to evolve, promising even greater efficiency and reliability for future applications.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025