- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Dec . 14, 2024 10:55 Back to list

high quality transmission belts

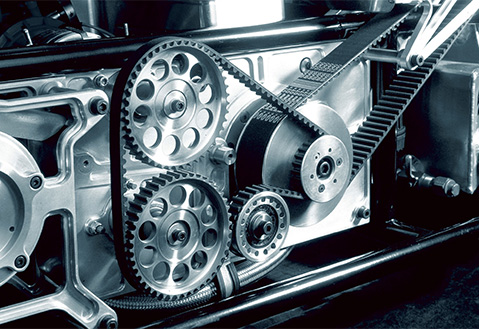

High-Quality Transmission Belts The Backbone of Modern Machinery

In the heart of modern machinery and technology lies an often-underappreciated component transmission belts. These essential parts facilitate the transfer of power and motion between various mechanical elements, ensuring smooth and efficient operation across a diverse range of applications, from automotive systems to industrial machinery. The importance of high-quality transmission belts cannot be overstated, as they play a critical role in ensuring performance, durability, and reliability.

Understanding Transmission Belts

Transmission belts are flexible loops made out of various materials, designed to transmit power from one part of a machine to another through the process of friction. They are commonly used in belts and pulleys, connecting engines to wheels in vehicles, and enabling the operation of conveyor systems, fans, and other machinery components. The types of transmission belts include V-belts, flat belts, timing belts, and serpentine belts, each optimized for specific applications based on factors such as load, speed, and environmental conditions.

The Importance of Quality

The quality of a transmission belt directly impacts the overall performance of the machinery it serves

. High-quality belts offer several advantages, including1. Durability and Longevity Premium materials and advanced manufacturing processes enhance the resistance of transmission belts to wear, heat, and various chemical agents. This durability translates into a longer service life, reducing the frequency of replacements and minimizing disruption in operations.

high quality transmission belts

2. Efficiency High-quality belts are designed to minimize slippage and maximize power transfer efficiency. This leads not only to better performance but also to energy savings—an essential consideration for businesses looking to reduce operating costs.

3. Reliability A robust transmission belt contributes to the reliability of a machine. High-quality belts are less prone to breaking or failing under high loads, ensuring consistent performance and reducing downtime due to mechanical failures.

4. Noise Reduction Many high-quality belts are engineered to operate more quietly than their lower-quality counterparts. This feature is particularly important in environments where noise levels must be minimized for safety or comfort.

Choosing the Right Transmission Belt

When selecting a transmission belt, several factors must be taken into account to ensure optimal performance. These include the type of machinery, the load requirements, environmental conditions (such as exposure to heat, moisture, and chemicals), and the specific application. Consulting with a supplier or manufacturer that specializes in high-quality transmission belts can provide valuable insights and help in making an informed decision.

Conclusion

As industries continue to evolve and demand more efficient and reliable machinery, the significance of high-quality transmission belts becomes increasingly evident. These components, often overlooked, are crucial to the successful operation of many systems. Investing in superior transmission belts not only enhances the performance and longevity of equipment but also contributes to overall operational efficiency and cost-effectiveness. In a world where every detail counts, ensuring the quality of transmission belts can make all the difference in maintaining a competitive edge. Whether in automotive applications, manufacturing processes, or everyday machinery, high-quality transmission belts stand as the backbone in the seamless operation of modern technology.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025