- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 04, 2024 11:18 Back to list

Understanding the Mechanics and Applications of Flat Transmission Belts in Industry

Understanding Flat Transmission Belts Mechanics, Applications, and Advantages

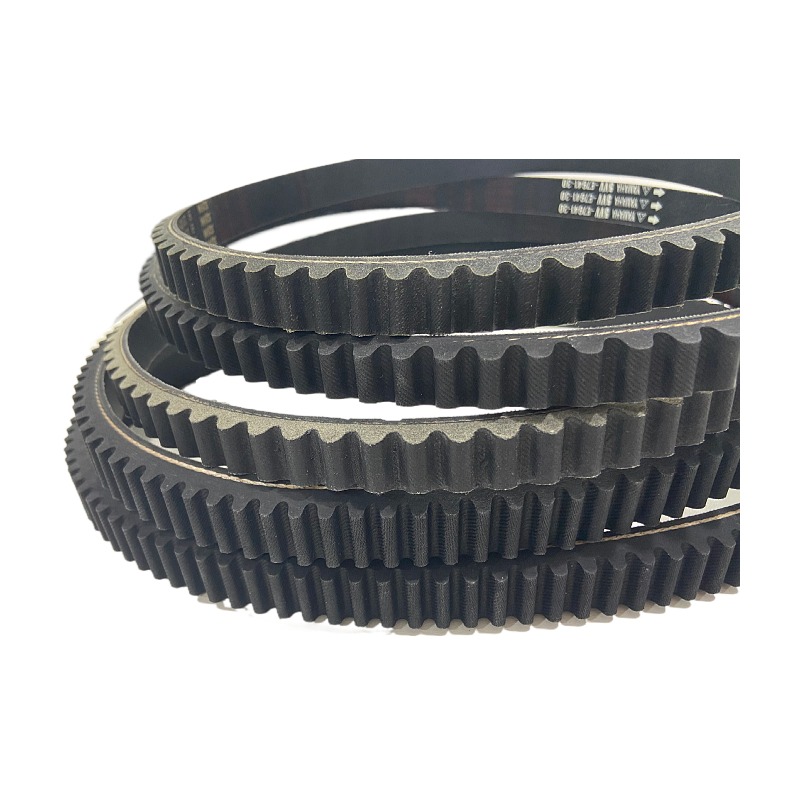

Flat transmission belts are an integral component in various mechanical systems, offering an efficient means of transferring power between rotating shafts. These belts, characterized by their flat, wide shape as opposed to conventional round belts, provide unique benefits and are employed across diverse industries. In this article, we will delve into the mechanics of flat transmission belts, their applications, and the advantages they offer.

Mechanics of Flat Transmission Belts

Flat belts are generally made from materials such as leather, rubber, or fabrics, often reinforced with materials like steel or polyester to improve strength and durability. The design of these belts allows them to span long distances between pulley systems while accommodating varying degrees of tension. When power is transferred through a flat transmission belt, friction between the belt and the pulleys allows for the effective transfer of energy.

Key parameters influencing the performance of flat belts include the belt's width, thickness, and the friction coefficient between the belt and the pulley surface. Proper tension management is critical; insufficient tension can lead to slippage, while excessive tension can result in premature wear or even component failure. Thus, designing a flat belt system requires careful consideration of these factors to ensure optimal performance.

Applications of Flat Transmission Belts

Flat transmission belts are widely used in a variety of applications. In industrial settings, they are frequently found in conveyor systems, where they transport materials from one location to another. These belts are particularly beneficial in applications requiring high power transmission over long distances, such as in mining or manufacturing processes.

While industrial applications are significant, flat belts also play a critical role in consumer goods. For instance, they are present in certain types of automotive engines, where they facilitate the transfer of power to water pumps, alternators, and other ancillary components. This versatility extends to household appliances as well, where flat belts can be found in vacuum cleaners and washing machines.

flat transmission belt

Advantages of Flat Transmission Belts

Flat transmission belts offer several advantages over other belt types. One of the primary benefits is their ability to handle high-power loads while maintaining efficiency. The large contact surface area between the belt and the pulleys enhances friction, promoting effective power transfer without requiring excessive tension.

Moreover, the flat design allows for easy modification and adjustment. Unlike V-belts, which may need specialized routing or fitting, flat belts can be cut to length and adjusted more readily in existing systems. This adaptability is crucial in manufacturing environments where machinery must often be reconfigured or adjusted to meet production demands.

Flat belts also generally require less maintenance than other types. With fewer moving parts and the availability of durable materials, these belts tend to have longer lifespans, contributing to lower overall operational costs. Their simplicity allows for easier installation and replacement, minimizing downtime in production facilities.

Additionally, flat transmission belts can be manufactured in various widths and designs to suit specific applications. This customization ensures that they can meet the unique demands of different industries, from heavy-duty machinery to delicate consumer appliances.

Conclusion

Flat transmission belts serve as a vital element in numerous mechanical systems, facilitating effective power transmission in a wide range of applications. Their mechanical design, coupled with their adaptability and efficiency, makes them a preferred choice in various industries. Whether in industrial machinery or household appliances, flat belts have demonstrated their reliability and effectiveness, ensuring that businesses can operate smoothly while providing consumers with dependable products. As technology advances and industries evolve, the role of flat transmission belts will continue to grow, underscoring the importance of this often-overlooked component in modern engineering.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025