- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 07, 2024 17:56 Back to list

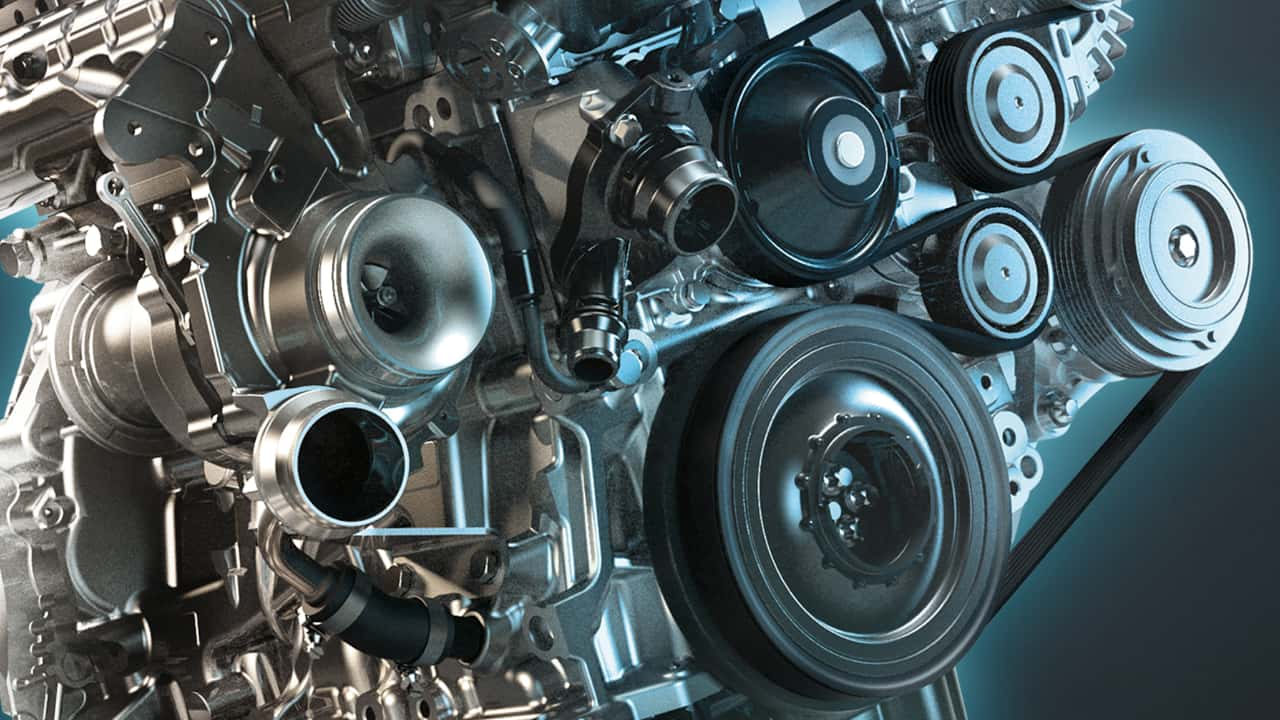

Rubber V Belts for Tractors to Enhance Performance and Durability

Understanding Rubber V-Belts for Tractors Essential Components for Smooth Operation

In the world of agricultural machinery, tractors stand out as vital equipment, enabling farmers to perform tasks with enhanced efficiency. Among the many components that contribute to a tractor's performance, the rubber V-belt plays a crucial role in ensuring the smooth operation of various systems. This article delves into the significance of rubber V-belts, their construction and types, and some maintenance tips for optimal use in tractors.

What are Rubber V-Belts?

Rubber V-belts are mechanical components that transfer power from one part of a machine to another, typically connecting the engine to the various systems, such as the alternator, water pump, and other accessories. The V shape of the belt allows it to fit snugly in the pulley, providing efficient grip and reducing slippage. This design is essential in heavy-duty applications like tractors, where significant power surges are common.

Construction and Design

Rubber V-belts are constructed from high-quality rubber, providing flexibility and durability. The belts often feature reinforced fibers, such as polyester or nylon, which enhance their strength and resistance to wear and tear. The grooves on the inside surface of the belts are designed to increase traction against the pulleys, minimizing the risk of slippage even during intense operation.

The dimensions of a rubber V-belt are critical, with various sizes available to accommodate different tractor models. A well-fitted belt is essential for optimal performance, as an ill-fitting belt can lead to premature wear, reduced efficiency, and even mechanical failure.

Types of Rubber V-Belts

There are several types of rubber V-belts commonly used in tractors

1. Classic V-Belts These are the traditional designs and are widely used in various applications. They provide good performance and are cost-effective.

2. Cogged V-Belts With notches or cogs on the inner surface, cogged V-belts offer increased flexibility and can bend around smaller pulleys, making them ideal for high-torque applications.

auto belt\/rubber v belt for tractors

4. Heavy-Duty V-Belts Built for extreme conditions, heavy-duty belts can withstand high levels of stress, making them perfect for large-scale agricultural machinery.

Maintaining Rubber V-Belts

To ensure the longevity and efficiency of rubber V-belts, regular maintenance is essential. Here are some tips for proper upkeep

1. Regular Inspections Periodically check the belts for signs of wear, such as cracking, fraying, or glazing. If any damage is visible, it’s crucial to replace the belt to avoid further complications.

2. Proper Tensioning Ensure that the belts are correctly tensioned. A belt that is too loose can slip, while a belt that is too tight can lead to premature wear on both the belt and the pulleys.

3. Cleanliness Keep the belts and pulleys clean. Dirt and debris can cause excessive wear and impact the efficiency of power transfer. Regular cleaning will promote better performance.

4. Alignment Misaligned pulleys can result in uneven wear on the belts. Regularly check that the pulleys are correctly aligned to ensure even distribution of stress across the belt.

5. Replacement Schedule Understand the lifespan of your V-belts and replace them as part of a scheduled maintenance plan. This proactive approach can prevent unexpected breakdowns during critical farming operations.

Conclusion

Rubber V-belts are integral components that significantly impact the performance and reliability of tractors. By understanding their construction, types, and maintenance requirements, farmers can ensure that their machinery operates at peak efficiency. Regular attention to these vital components will not only extend their lifespan but also contribute to the overall productivity of agricultural operations. Investing time in maintenance will yield rewarding results, enabling tractors to perform effectively through various farming challenges.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025