- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ژوئن . 12, 2024 11:50 Back to list

tooth belt can be replaced with drive belt in a similar short sentence. For example The drive belt powers the engine's components.

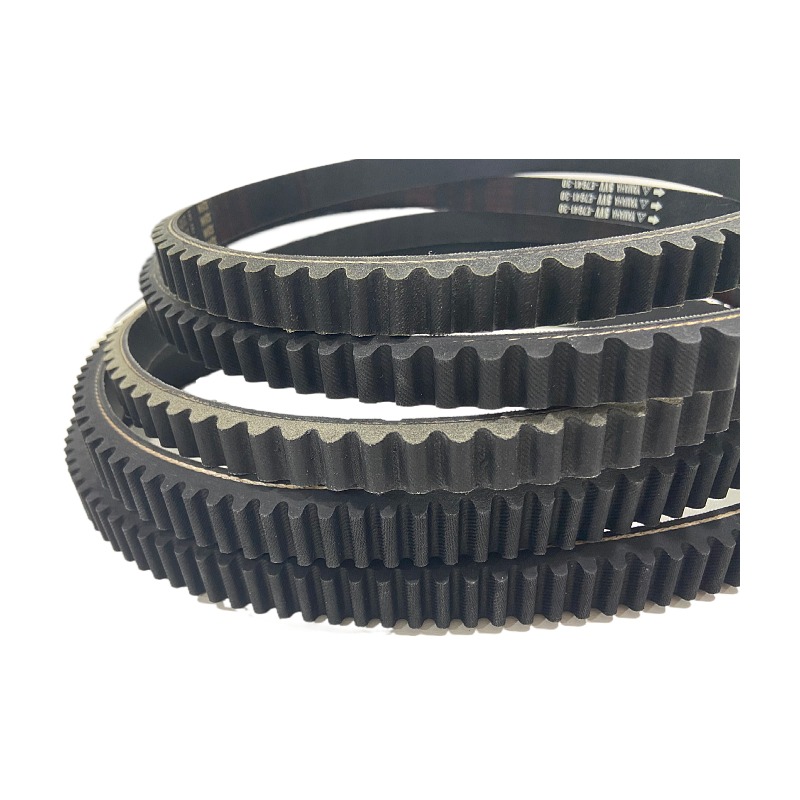

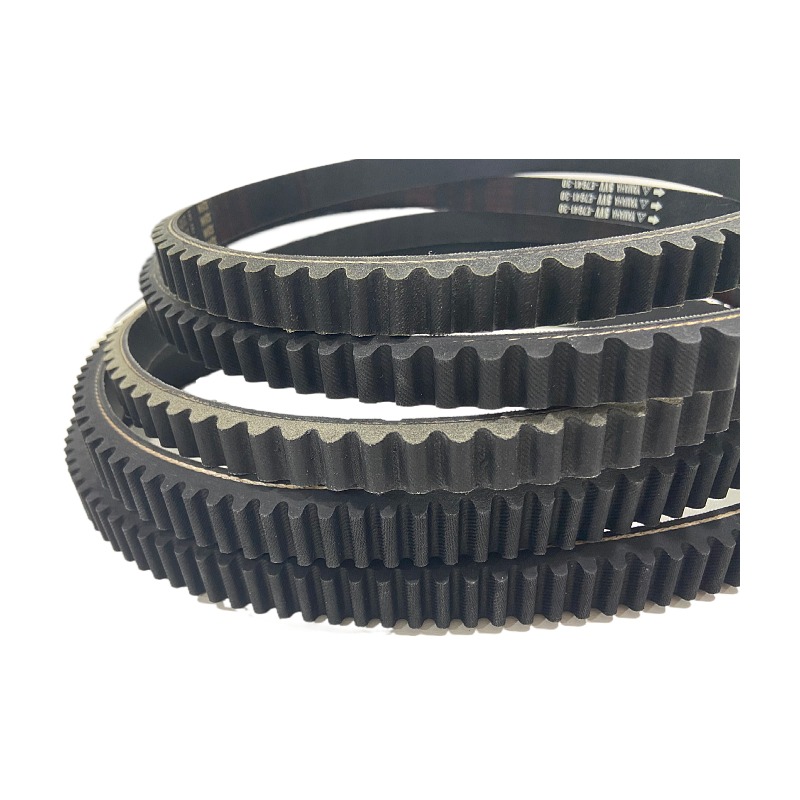

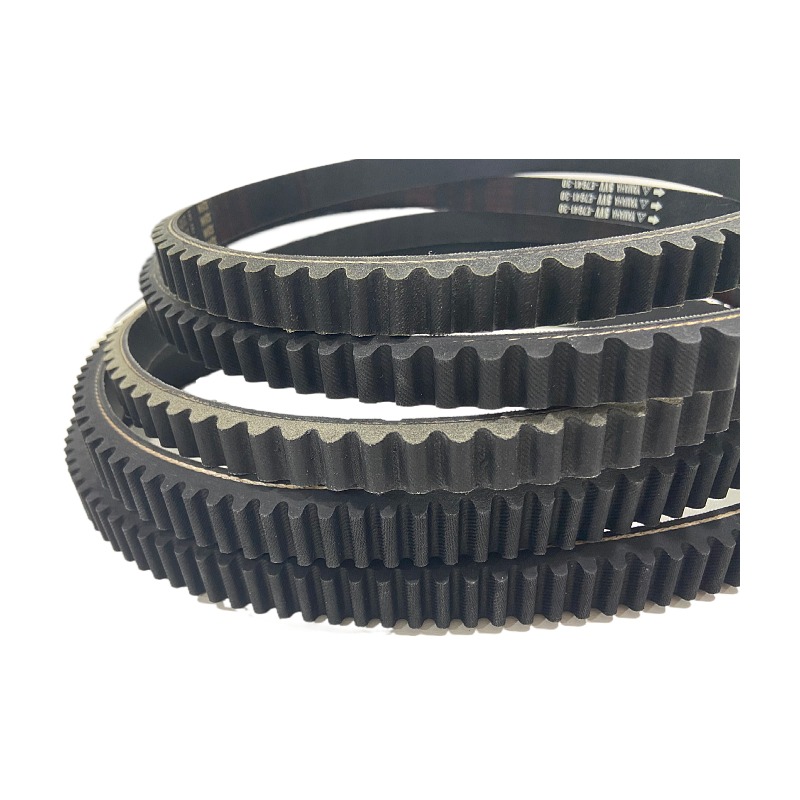

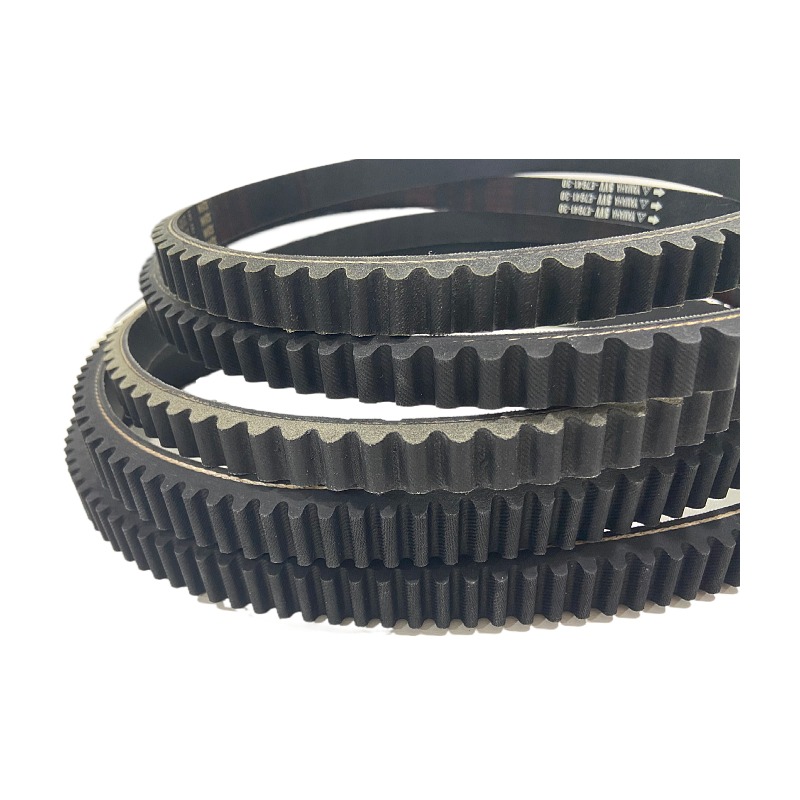

The Vital Role of Tooth Belts in Modern Machinery

A tooth belt, also known as a synchronous belt, is an essential component in numerous mechanical systems, playing a pivotal role in power transmission and precision operations. Its name derives from the unique toothed profile on the belt's surface, which meshes with corresponding grooves on the pulleys, enabling it to transmit force with exceptional efficiency and accuracy.

Tooth belts are typically made from a flexible polyurethane or rubber material, reinforced with high-tensile strength polyester cords for added durability and strength. The teeth, usually made of a harder material like nylon or steel, ensure that the belt grips the pulley firmly, reducing slippage and enhancing overall performance. This design allows for a smoother, quieter operation compared to conventional flat belts, making them ideal for applications where precise speed control and low noise levels are crucial.

The efficiency of tooth belts lies in their ability to maintain constant speed and tension, even under varying loads. This characteristic is particularly beneficial in industries such as automotive, aerospace, and manufacturing, where consistent speed and power transmission are non-negotiable. They are also widely used in dental equipment, computer printers, and audio-visual equipment, demonstrating their versatility across various sectors.

Moreover, tooth belts have a longer lifespan than other transmission methods due to their low maintenance requirements

Moreover, tooth belts have a longer lifespan than other transmission methods due to their low maintenance requirements Moreover, tooth belts have a longer lifespan than other transmission methods due to their low maintenance requirements

Moreover, tooth belts have a longer lifespan than other transmission methods due to their low maintenance requirements

Moreover, tooth belts have a longer lifespan than other transmission methods due to their low maintenance requirements

Moreover, tooth belts have a longer lifespan than other transmission methods due to their low maintenance requirements tooth belt. They require minimal lubrication, resist wear and tear, and can withstand harsh environmental conditions. Their compact design also allows for smaller, more compact machines, contributing to space-saving solutions in engineering.

Despite these advantages, proper installation and maintenance are crucial to ensure the optimal functioning of tooth belts. Regular inspection for signs of wear, correct tensioning, and timely replacement are vital to prevent premature failure.

In conclusion, the tooth belt is more than just a simple mechanical part; it is a sophisticated engineering solution that has revolutionized power transmission in modern machinery. Its precision, efficiency, and durability make it a go-to choice for engineers seeking reliable and efficient performance. As technology continues to evolve, the role of tooth belts is likely to become even more significant, contributing to the development of faster, quieter, and more efficient machines.

tooth belt. They require minimal lubrication, resist wear and tear, and can withstand harsh environmental conditions. Their compact design also allows for smaller, more compact machines, contributing to space-saving solutions in engineering.

Despite these advantages, proper installation and maintenance are crucial to ensure the optimal functioning of tooth belts. Regular inspection for signs of wear, correct tensioning, and timely replacement are vital to prevent premature failure.

In conclusion, the tooth belt is more than just a simple mechanical part; it is a sophisticated engineering solution that has revolutionized power transmission in modern machinery. Its precision, efficiency, and durability make it a go-to choice for engineers seeking reliable and efficient performance. As technology continues to evolve, the role of tooth belts is likely to become even more significant, contributing to the development of faster, quieter, and more efficient machines.

Moreover, tooth belts have a longer lifespan than other transmission methods due to their low maintenance requirements

Moreover, tooth belts have a longer lifespan than other transmission methods due to their low maintenance requirements

Moreover, tooth belts have a longer lifespan than other transmission methods due to their low maintenance requirements

Moreover, tooth belts have a longer lifespan than other transmission methods due to their low maintenance requirements tooth belt. They require minimal lubrication, resist wear and tear, and can withstand harsh environmental conditions. Their compact design also allows for smaller, more compact machines, contributing to space-saving solutions in engineering.

Despite these advantages, proper installation and maintenance are crucial to ensure the optimal functioning of tooth belts. Regular inspection for signs of wear, correct tensioning, and timely replacement are vital to prevent premature failure.

In conclusion, the tooth belt is more than just a simple mechanical part; it is a sophisticated engineering solution that has revolutionized power transmission in modern machinery. Its precision, efficiency, and durability make it a go-to choice for engineers seeking reliable and efficient performance. As technology continues to evolve, the role of tooth belts is likely to become even more significant, contributing to the development of faster, quieter, and more efficient machines.

tooth belt. They require minimal lubrication, resist wear and tear, and can withstand harsh environmental conditions. Their compact design also allows for smaller, more compact machines, contributing to space-saving solutions in engineering.

Despite these advantages, proper installation and maintenance are crucial to ensure the optimal functioning of tooth belts. Regular inspection for signs of wear, correct tensioning, and timely replacement are vital to prevent premature failure.

In conclusion, the tooth belt is more than just a simple mechanical part; it is a sophisticated engineering solution that has revolutionized power transmission in modern machinery. Its precision, efficiency, and durability make it a go-to choice for engineers seeking reliable and efficient performance. As technology continues to evolve, the role of tooth belts is likely to become even more significant, contributing to the development of faster, quieter, and more efficient machines. Share:

Latest news

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025