- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

اکتبر . 22, 2024 01:55 Back to list

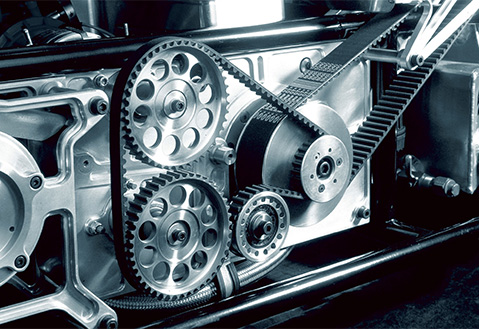

Understanding the Benefits and Applications of Synchroflex Belts in Modern Machinery

Understanding Synchroflex Belts A Comprehensive Overview

In the world of mechanical drives, efficiency and precision are paramount. Among the various components that facilitate mechanical movement, the synchroflex belt stands out due to its unique design and functionality. This innovative type of belt has become increasingly popular in various industrial applications, owing to its remarkable ability to transmit power effectively while minimizing slippage and wear.

What is a Synchroflex Belt?

Developed initially for synchronous drive mechanisms, synchroflex belts are a type of timing belt characterized by their tooth-like projections. These projections, often referred to as teeth or profiles, interlock with corresponding grooves on a pulley system. This interlocking mechanism ensures that the motion between the belt and the pulley is synchronized, allowing for precise control of mechanical motion.

Synchroflex belts are typically made from materials like polyurethane or rubber, which are reinforced with high-strength fibers to provide enhanced durability and flexibility. The choice of material is crucial, as it influences the belt's performance across various temperatures, operating conditions, and levels of flexibility.

Benefits of Synchroflex Belts

One of the primary benefits of synchroflex belts is their ability to minimize slippage

. Unlike traditional friction belts, which rely on the friction between the belt and pulley to transmit motion, synchroflex belts maintain a consistent grip thanks to their tooth design. This translates to improved accuracy in speed and position control, making them ideal for applications where exact timing is critical.synchroflex belt

Another significant advantage is reduced wear and tear. The design of synchroflex belts allows for consistent load distribution over a larger surface area, which decreases the likelihood of belt failure and extends the lifespan of both the belt and the associated pulleys. This efficiency not only lowers replacement costs but also reduces maintenance downtime in industrial settings.

Additionally, synchroflex belts offer versatility. They can be designed in various sizes, shapes, and tooth profiles to meet specific application requirements. From small, compact devices to large industrial machinery, synchroflex belts can be adapted to provide optimal performance across a wide range of environments.

Applications of Synchroflex Belts

Synchroflex belts are employed in numerous industrial applications. They play a vital role in the manufacturing sector, powering conveyor systems, robotics, and assembly lines. In the automotive industry, these belts are commonly used in engine timing mechanisms and other critical components where precise synchronization is essential.

Beyond manufacturing, synchroflex belts find applications in the printing industry, textile machinery, and packaging equipment. Their ability to operate at high speeds while maintaining accuracy makes them a preferred choice in environments that demand consistent performance.

Conclusion

In summary, synchroflex belts are an indispensable component in modern mechanical systems, engineered to deliver efficiency, reliability, and precision. Their unique design and material properties contribute to reduced slippage, lower wear, and exceptional versatility, making them suitable for a myriad of applications. As industries continue to evolve and demand higher performance, synchroflex belts will undoubtedly remain a foundational technology in mechanical drive systems. Understanding their functionality and benefits empowers engineers and manufacturers to make informed decisions that optimize their operations and enhance productivity.

-

Durable Diesel Engine Belt with GPT-4-Turbo AI Tech | Precision Fit

NewsAug.04,2025

-

High-Quality Tensioner Belt Pulley - Durable & Efficient

NewsAug.03,2025

-

Premium Timing Belt Factory | AI-Optimized Solutions

NewsAug.02,2025

-

Premium Custom V Belts Enhanced with GPT-4 Turbo AI

NewsAug.01,2025

-

Car Serpentine Belt: AI-Optimized Performance with GPT-4-Turbo

NewsJul.31,2025

-

Heat Joining Drive Belt | High-Durability Fusion Solution

NewsJul.31,2025