- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Aza . 30, 2024 07:46 Back to list

Leading Manufacturers of V-Belts for Diverse Industrial Applications

Understanding V-Belts and Their Manufacturers

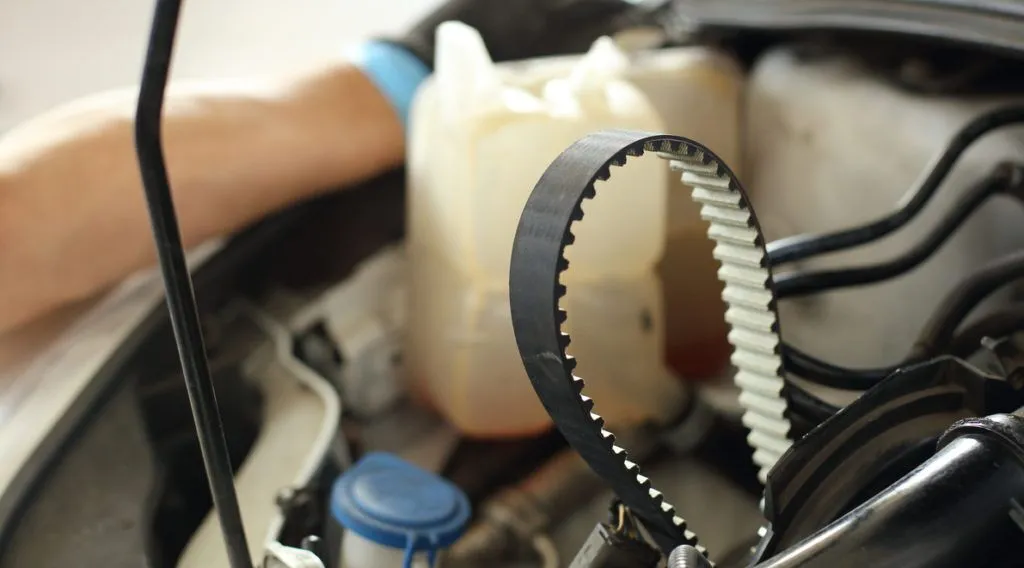

V-belts are an essential component in various mechanical systems, playing a crucial role in the transmission of power between different components. Widely used in industrial machinery, automotive systems, and agricultural equipment, V-belts are designed to offer efficient power transfer by providing a strong grip on pulleys while maintaining flexibility and longevity.

What Are V-Belts?

V-belts are named for their trapezoidal cross-section, which resembles the letter V. This design enables the belt to fit snugly into the grooves of the pulleys. The contact surface between the belt and the pulley is maximized, allowing for superior friction and enabling the belt to transmit higher levels of torque effectively. V-belts are typically made from rubber, with layers of fabric and steel reinforcing to enhance their strength and durability.

One of the primary advantages of V-belts is their ability to absorb shocks and vibrations. This feature is particularly beneficial in systems where sudden changes in speed or load occur, such as in heavy machinery. Additionally, V-belts are available in various configurations, including classical V-belts, narrow V-belts, and cogged V-belts, tailored to meet the specific demands of different applications.

The Importance of Quality Manufacturers

Choosing a reliable manufacturer is crucial for ensuring the performance and longevity of V-belts. High-quality V-belts are produced using advanced materials and manufacturing processes that meet rigorous industry standards. A reputable manufacturer invests in research and development to innovate and improve their products continually.

One significant aspect to consider when selecting a V-belt manufacturer is their adherence to quality control practices. Manufacturers that implement stringent quality checks throughout the production process can minimize defects and ensure that their belts consistently meet specified tolerances.

Some of the well-known manufacturers in the V-belt industry include Gates, Continental, and Dayco. These companies have established a reputation for producing durable and high-performance V-belts that cater to various applications across different sectors. Gates, for example, has an extensive catalog that ranges from traditional V-belts to specialized belts designed for unique applications, demonstrating their commitment to innovation.

Factors to Consider When Selecting V-Belts

v belts manufactures

When sourcing V-belts from manufacturers, there are several factors to consider

1. Material Quality The type of materials used in the belt's construction directly affects its durability and performance. Look for belts made from high-performance elastomers that resist wear, heat, and oil.

2. Application Compatibility Ensure that the V-belt is suitable for your specific application. Different machinery may require belts with particular specifications.

3. Sizing and Fit It is critical to select the right size of the V-belt to ensure optimal performance. Manufacturers usually provide detailed specifications and sizing charts to assist customers in finding the perfect fit.

4. Certifications and Standards Opt for manufacturers whose products comply with international quality standards. Certifications from organizations like ISO can indicate a manufacturer’s commitment to quality.

5. Customer Support and Warranty Consider manufacturers that offer excellent customer service and warranties. This support can be invaluable if you encounter issues with the product.

The Future of V-Belts

As industries continue to evolve, so too do the demands placed on V-belts. The increasing emphasis on energy efficiency and sustainability is driving manufacturers to innovate new materials and designs that optimize performance while minimizing environmental impact. Additionally, advancements in technology, such as condition monitoring and predictive maintenance, are set to revolutionize how V-belts are used and maintained in various applications.

In conclusion, V-belts are indispensable components in the machinery that drives numerous industries. Understanding the significance of quality manufacturers and considering essential factors when selecting V-belts can lead to improved performance and efficiency in mechanical systems. As the demand for innovative and high-performance V-belts grows, manufacturers will be at the forefront, developing solutions that meet the ever-changing needs of the market. Selecting the right manufacturer can make all the difference in the reliability and efficiency of the equipment that relies on these essential components.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025