- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

dets. . 20, 2024 18:46 Back to list

v belt pulley sizes

Understanding V-Belt Pulley Sizes for Efficient Power Transmission

In the realm of mechanical engineering and design, the selection of components plays a critical role in the overall efficiency and functionality of a system. One vital component in many mechanical systems is the V-belt pulley. Understanding V-belt pulley sizes is essential for optimizing the performance of machines, ensuring that power is transmitted effectively and efficiently.

What is a V-Belt Pulley?

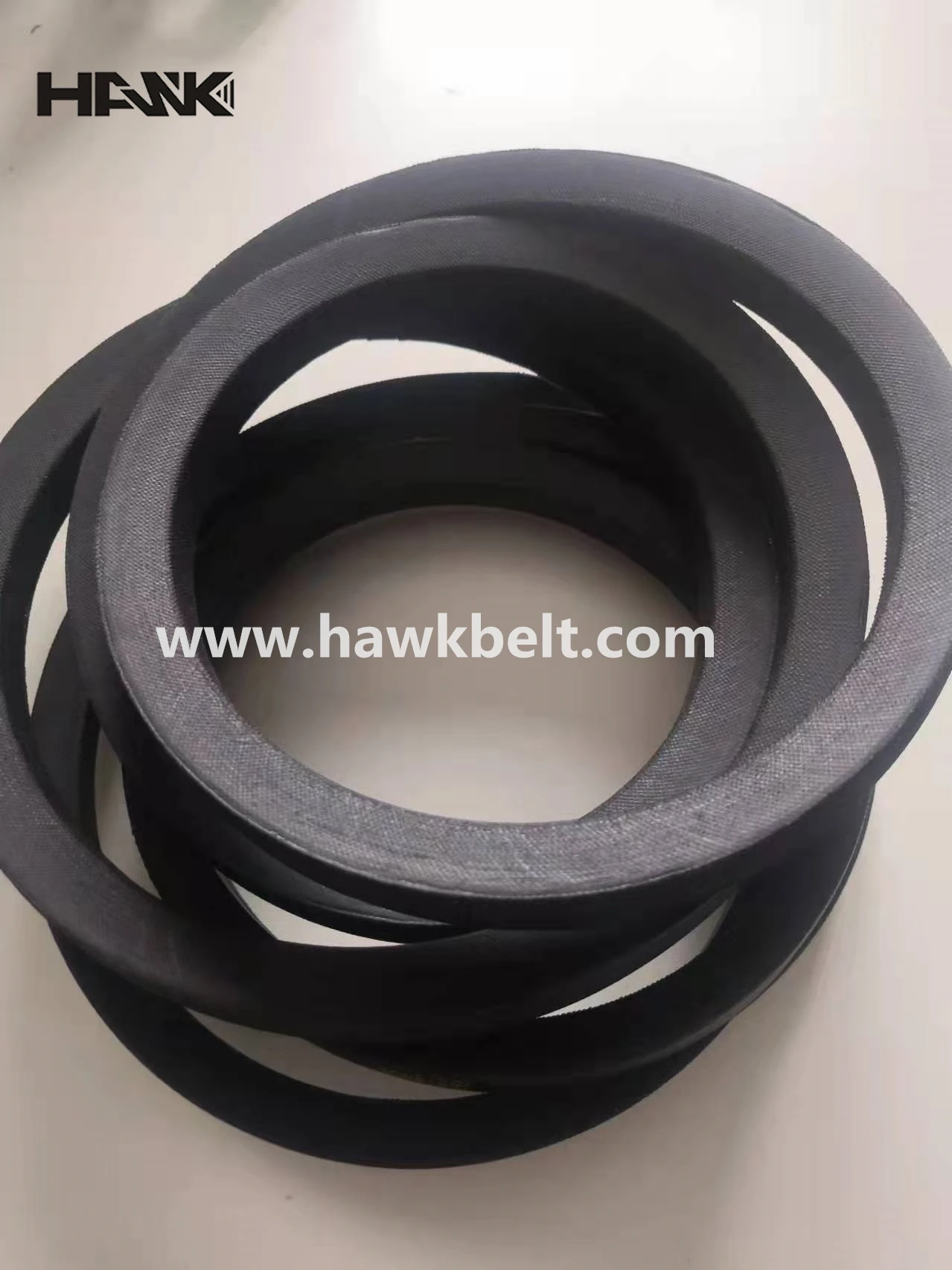

A V-belt pulley is designed to work in conjunction with V-belts, which are a type of belt with a trapezoidal cross-section. The design of the pulley includes grooves that match the shape of the V-belt, facilitating efficient grip and power transfer. V-belt pulleys are commonly used in various applications, including automotive engines, agricultural machinery, and industrial equipment.

Importance of Correct Pulley Sizes

The size of a V-belt pulley is crucial for several reasons

1. Power Transmission Efficiency Correct pulley sizing ensures that the system operates efficiently, minimizing energy losses due to slippage or inadequate fit between the belt and pulley. An improperly sized pulley can lead to increased wear and tear on both the belt and pulley, reducing the lifespan of the components.

2. Speed Ratio The ratio of the size of different pulleys in a system determines the speed at which components operate. For instance, in a scenario where a smaller pulley drives a larger pulley, the output speed is reduced, which can be useful in applications requiring high torque and lower speeds. Conversely, using a larger driving pulley allows for increased speed at the expense of torque.

3. Alignment and Tension Properly sized pulleys help maintain correct alignment in the system, which is essential for preventing additional wear and enhancing the performance of the belt drive. Pulley size also affects the tension on the belt; too much tension can cause premature failures, while too little can lead to slippage.

Key Measurements for V-Belt Pulleys

When considering V-belt pulley sizes, several measurements are essential

1. Pitch Diameter This is the diameter of an imaginary circle that represents the point at which the belt effectively contacts the pulley. It influences the speed and torque characteristics of the system.

v belt pulley sizes

2. Belt Width The width of the V-belt impacts how much power can be transmitted. A wider belt allows for a higher load capacity but may require a larger pulley size.

3. Groove Dimensions The depth and shape of the grooves in the pulley need to match the specifications of the V-belt being used. Common industry standards define specific dimensions for V-belt shapes, such as A, B, C, and so on.

4. Number of Grooves The number of grooves in a pulley must match the number of belts used in the system. Missing grooves can lead to instability and performance issues.

Selecting the Right V-Belt Pulley Size

Choosing the right V-belt pulley size depends on various factors, including the application requirements, the type and size of the V-belt, and other components within the power transmission system

1. Consult Manufacturer Specifications Each V-belt and pulley combination will usually come with specific guidelines provided by manufacturers. Consulting these guidelines ensures compatibility and performance alignment.

2. Understand Load Requirements Assess the load that will be transmitted through the system. This will help in determining not only the size of the pulley but also the material and construction type suitable for the application.

3. Calculate Speed Ratios Determine the input and output speeds required in your application. This information will guide the selection of appropriate sizes for the driving and driven pulleys to achieve the desired mechanical advantage.

4. Plan for Maintenance and Adjustments Over time, belts stretch and wear out, necessitating regular maintenance checks. Ensure that your selection allows for adjustments in tension to prolong the life of the belt and pulley system.

Conclusion

Understanding and selecting the appropriate V-belt pulley sizes is fundamental in creating an effective power transmission system. Correct sizing enhances efficiency, ensures durability, and optimizes the performance of machinery in various applications. By considering measurements, application requirements, and manufacturer guidelines, engineers can make informed choices that lead to successful mechanical designs. Whether in an industrial setting or a simple home project, paying attention to these details can result in significant long-term benefits.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025