- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

veebr. . 05, 2025 04:50 Back to list

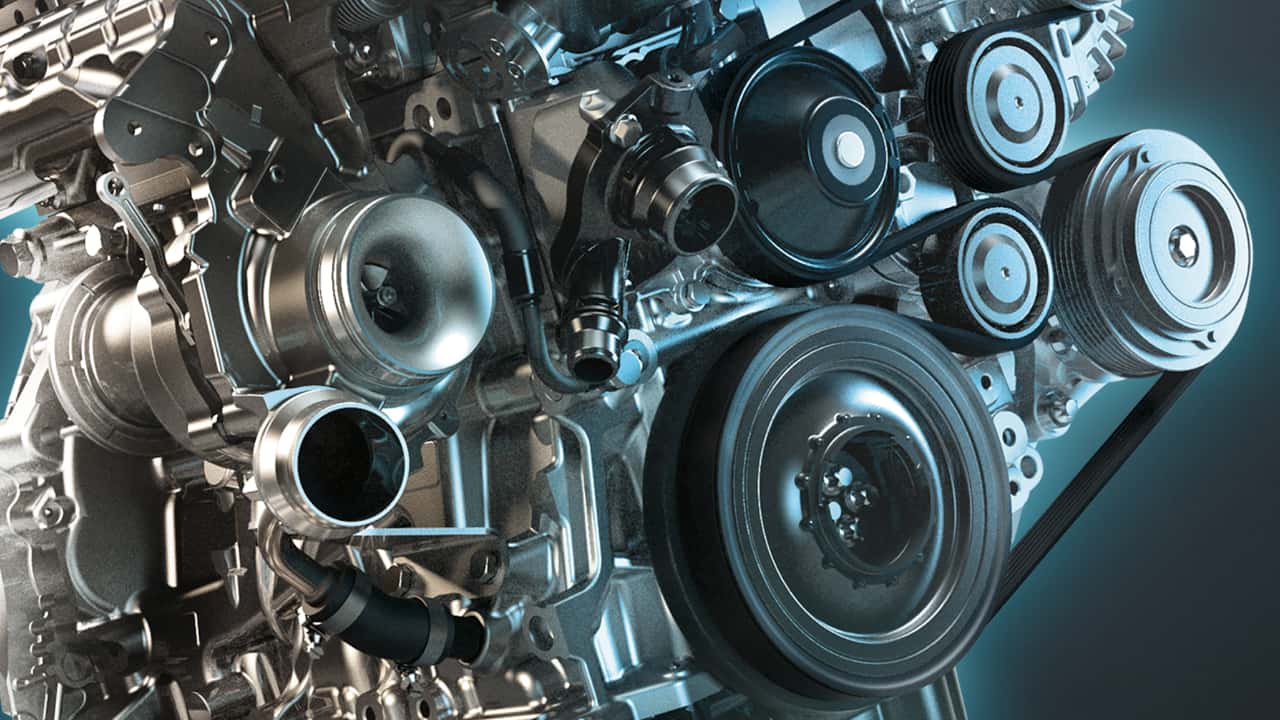

Generator Efficient 13X900LA V-Belt Transmission Belts with Rubber Gear Transmission dynamo belt

Transmission rubber V belts play an indispensable role in the world of mechanics and machinery, seamlessly transferring power and motion with unparalleled efficiency. As a cornerstone in various industries, understanding their use and benefits can lead to significant advancements in machine performance.

Trustworthiness is paramount in transmission systems, where failure can lead to substantial financial losses or operational setbacks. Implementing rubber V belts from recognized and certified suppliers guarantees not only compliance with industry standards but also peace of mind. Continuous professional training in belt technology and ongoing partnerships with experts provide an additional layer of assurance. Regular audits and quality checks are fundamental to maintaining and verifying the integrity and performance of these essential components. For industries like automotive, aerospace, and manufacturing, where precision and reliability are paramount, transmission rubber V belts are vital. In these sectors, defects or failures in belt systems can have far-reaching consequences, impacting safety, efficiency, and profitability. Therefore, investing in high-quality rubber V belts and collaborating with experienced professionals to maintain these systems is crucial. To complement their functionality, advancements in materials and engineering continue to redefine the capabilities of rubber V belts. For instance, integrating synthetic materials and fibers can boost strength and reduce elongation, while innovative designs can minimize energy loss and drive system efficiency. This continuous evolution in technology ensures that transmission rubber V belts remain adaptable and robust in diverse applications. Ultimately, the key to harnessing the full potential of transmission rubber V belts lies in comprehensive knowledge and careful application. By focusing on real-world experience, professional expertise, recognized authority, and building trust, industries can maximize the performance and lifespan of these vital components. Companies capitalizing on these principles not only enhance their operational competence but also secure a competitive edge in their respective domains.

Trustworthiness is paramount in transmission systems, where failure can lead to substantial financial losses or operational setbacks. Implementing rubber V belts from recognized and certified suppliers guarantees not only compliance with industry standards but also peace of mind. Continuous professional training in belt technology and ongoing partnerships with experts provide an additional layer of assurance. Regular audits and quality checks are fundamental to maintaining and verifying the integrity and performance of these essential components. For industries like automotive, aerospace, and manufacturing, where precision and reliability are paramount, transmission rubber V belts are vital. In these sectors, defects or failures in belt systems can have far-reaching consequences, impacting safety, efficiency, and profitability. Therefore, investing in high-quality rubber V belts and collaborating with experienced professionals to maintain these systems is crucial. To complement their functionality, advancements in materials and engineering continue to redefine the capabilities of rubber V belts. For instance, integrating synthetic materials and fibers can boost strength and reduce elongation, while innovative designs can minimize energy loss and drive system efficiency. This continuous evolution in technology ensures that transmission rubber V belts remain adaptable and robust in diverse applications. Ultimately, the key to harnessing the full potential of transmission rubber V belts lies in comprehensive knowledge and careful application. By focusing on real-world experience, professional expertise, recognized authority, and building trust, industries can maximize the performance and lifespan of these vital components. Companies capitalizing on these principles not only enhance their operational competence but also secure a competitive edge in their respective domains.

Share:

Latest news

-

High-Quality Tensioner Belt Pulley - Durable & Efficient

NewsAug.03,2025

-

Premium Timing Belt Factory | AI-Optimized Solutions

NewsAug.02,2025

-

Premium Custom V Belts Enhanced with GPT-4 Turbo AI

NewsAug.01,2025

-

Car Serpentine Belt: AI-Optimized Performance with GPT-4-Turbo

NewsJul.31,2025

-

Heat Joining Drive Belt | High-Durability Fusion Solution

NewsJul.31,2025

-

Timing Belt Video Guide: Selection, Design & Quality Insights

NewsJul.30,2025