- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Oct . 11, 2024 09:42 Back to list

micro timing belt

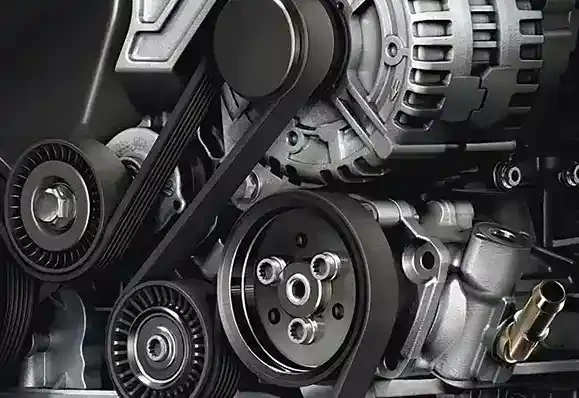

Understanding Micro Timing Belts A Key Component in Precision Engineering

In the realm of precision engineering, the micro timing belt is an essential component that plays a critical role in the performance and efficiency of various machinery. Timing belts, known for their durability and reliability, facilitate synchronized movement in machines, thereby ensuring the smooth functioning of mechanical systems. The evolution of micro timing belts has transformed industries relying on high precision, including automotive, robotics, and medical devices.

What is a Micro Timing Belt?

A micro timing belt is a narrow, high-precision belt designed for small-scale applications where space is limited. Unlike traditional timing belts, which are typically used in larger engines and machinery, micro timing belts are engineered to operate in compact systems. They are often made from advanced materials, such as polyurethane or rubber fortified with fiberglass or Kevlar, which enhances their strength, flexibility, and longevity. The unique toothed design of these belts allows them to mesh precisely with pulleys, minimizing slippage and ensuring accurate motion transfer.

Applications of Micro Timing Belts

Micro timing belts are increasingly used in various applications, thanks to their ability to provide precise control over movement. In the automotive industry, they are employed in engines for synchronizing the rotation of the crankshaft and camshaft, which is crucial for optimal performance. Similarly, in the field of robotics, micro timing belts are integral to the functioning of robotic arms and conveyors, facilitating accurate movements and positioning.

Moreover, the medical industry also benefits from micro timing belts, where they are used in devices such as MRI machines and surgical robots. Their precision allows for the careful movements required in delicate procedures, increasing the safety and accuracy of medical interventions. Additionally, manufacturing processes that require high-speed operations and tight tolerances also utilize micro timing belts to enhance productivity and maintain quality standards.

Advantages of Micro Timing Belts

micro timing belt

One of the primary advantages of micro timing belts is their ability to operate with minimal noise and vibration. This feature is particularly important in environments where noise reduction is a priority, such as medical and laboratory settings. Additionally, micro timing belts require minimal maintenance, a characteristic that translates into decreased downtime and lower operational costs for businesses.

Another advantage is their adaptability to various conditions. Micro timing belts can be engineered to withstand extreme temperatures, humid environments, and exposure to chemicals, making them suitable for diverse applications. This versatility ensures that they can meet the specific needs of different industries without compromising performance.

Challenges and Considerations

Despite their numerous advantages, micro timing belts also face certain challenges. One significant concern is the potential for wear and tear, especially in high-load applications. Over time, micro timing belts can stretch or become damaged, impacting the operation of the machinery. Therefore, regular monitoring and timely replacement are crucial to maintaining efficiency and preventing costly breakdowns.

Choosing the right micro timing belt involves considering factors such as load capacity, environmental conditions, and the specific requirements of the application. Consulting with manufacturers or experts in the field can provide valuable guidance in selecting the appropriate belt for optimal performance.

Conclusion

Micro timing belts are indispensable components in modern engineering, enabling precision and efficiency across a wide array of applications. Their unique properties offer manufacturers and engineers the tools necessary to create advanced machinery that meets the demands of today's fast-paced world. As technology continues to evolve, the importance of micro timing belts in achieving high performance and reliability in various industries will only grow, making them a focal point in the continuous quest for innovation and excellence in engineering.

-

Upgrade Power Steering Pump Belt for Smooth, Quiet Operation

NewsAug.27,2025

-

Precision Timing Belt & Chain: Engine Performance & Durability

NewsAug.26,2025

-

Precision Lathe Drive Belts: Durable & Reliable Performance

NewsAug.25,2025

-

84.5 Serpentine Belt: Durable & Precision Fit for Your Engine

NewsAug.24,2025

-

Premium Ribbed Drive Belts for Quiet Power Transmission

NewsAug.23,2025

-

High-Performance Vehicle Timing Belt for Engine Precision

NewsAug.22,2025