- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

nov . 06, 2024 21:40 Back to list

Understanding V-Belts in Transmission Systems for Enhanced Performance and Efficiency

Understanding V-Belts and Their Transmission Principles

V-belts are an essential component in the machinery and automotive industries, providing a reliable means of transmitting power between shafts. The design and construction of V-belts allow them to operate smoothly and efficiently, making them a preferred choice for both industrial and automotive applications.

What Are V-Belts?

A V-belt is a type of belt that has a trapezoidal cross-section, which is why it gets its name. The sides of the belt are angled, allowing it to fit snugly into a corresponding groove on the pulleys. This design enhances the frictional grip between the belt and the pulleys, enabling effective power transmission with minimal slippage. V-belts come in various sizes and materials, making them suitable for a wide range of applications, from small engines to large industrial machines.

How V-Belts Work

The fundamental principle behind V-belt operation is the transfer of rotational motion from one pulley to another. When one pulley, known as the drive pulley, rotates, it pulls the V-belt with it. The belt, fitting into the groove of the driven pulley, transmits this rotational force and causes the driven pulley to rotate. This is a straightforward yet effective method of power transfer.

The design of V-belts ensures that they can handle significant amounts of tension, which is crucial in high-torque applications. The wedge shape of the belt allows it to seat firmly within the pulley's groove, preventing slippage, which would lead to inefficient operation and wear. Furthermore, the durability of materials used in manufacturing V-belts contributes to their longevity, making them a cost-effective solution for power transmission.

Types of V-Belts

There are several types of V-belts available in the market, each designed for specific applications. The most common types include

1. Classical V-Belts These are the standard belts, often used in conventional applications. They are categorized into various sizes denoted typically by their width and height.

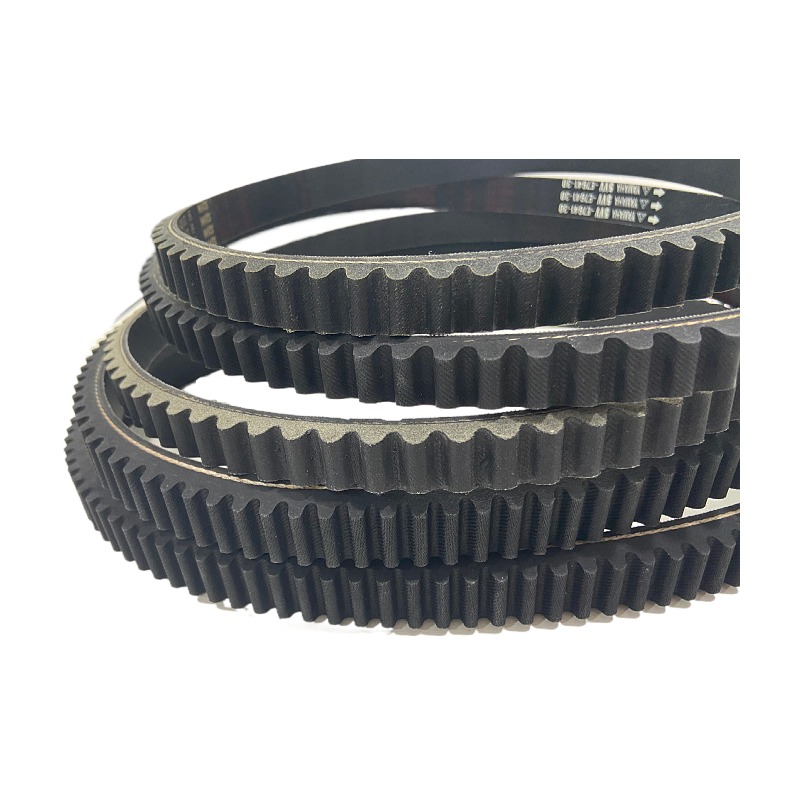

v-belts transmission 2150

2. Narrow V-Belts As the name suggests, these belts are narrower than classical V-belts, allowing for higher speed and smaller pulley diameters. They are ideal for applications requiring compact design without sacrificing power transmission.

3. Variable Speed V-Belts These belts are designed to operate in applications where the speed of operation can vary. They are often used in variable-speed drives to maintain performance across a range of operating conditions.

4. Cogged V-Belts Featuring notches along the top surface, cogged V-belts are designed to improve flexibility and reduce bending stress. This design allows them to work efficiently on smaller pulleys, where standard belts may falter.

Advantages of V-Belt Transmission

V-belt systems offer numerous advantages over other forms of power transmission. One of the most significant benefits is their efficiency. V-belts can transmit power effectively with minimal energy loss. Additionally, they operate quietly, minimizing noise pollution in industrial settings.

Another advantage of V-belts is their ability to absorb shock loads, making them ideal for applications that experience sudden changes in load. This ability to cushion impacts helps prolong the life of both the belt and the connected equipment.

Moreover, the installation and maintenance of V-belt systems are generally straightforward. With proper tensioning and alignment, V-belts can provide reliable service for long periods. Regular checks and adjustments help ensure optimal performance and avoid unexpected downtime.

Conclusion

In conclusion, V-belts are a critical component in numerous mechanical systems, providing effective power transmission through their innovative design. With different types available and the ability to operate efficiently under various conditions, V-belts are indispensable in both industrial and automotive applications. Understanding the characteristics and advantages of V-belts can help engineers and technicians select the right belt for their needs, ensuring reliability and optimal performance in power transmission systems. Whether you're working on a small machine or a large industrial unit, V-belts play a vital role in maintaining operational efficiency.

-

Upgrade Power Steering Pump Belt for Smooth, Quiet Operation

NewsAug.27,2025

-

Precision Timing Belt & Chain: Engine Performance & Durability

NewsAug.26,2025

-

Precision Lathe Drive Belts: Durable & Reliable Performance

NewsAug.25,2025

-

84.5 Serpentine Belt: Durable & Precision Fit for Your Engine

NewsAug.24,2025

-

Premium Ribbed Drive Belts for Quiet Power Transmission

NewsAug.23,2025

-

High-Performance Vehicle Timing Belt for Engine Precision

NewsAug.22,2025