- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

jan . 16, 2025 05:01 Back to list

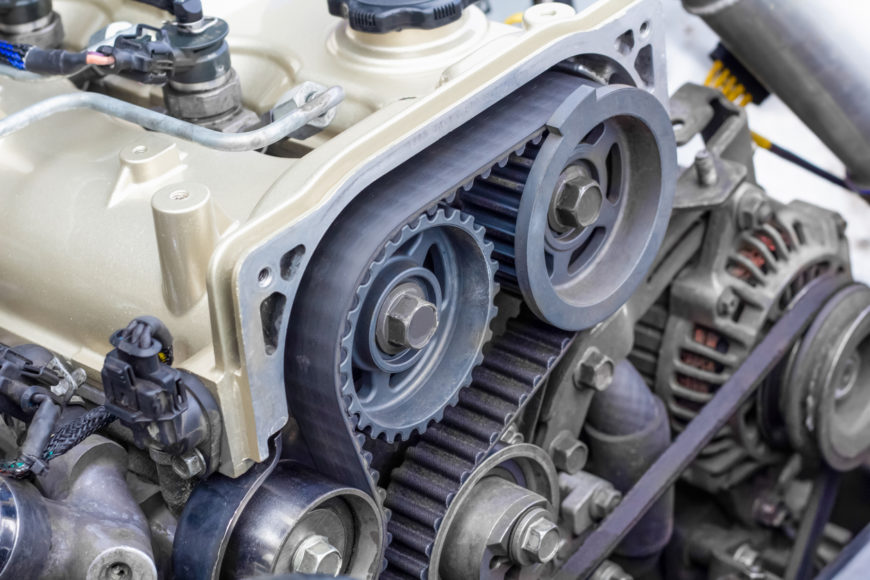

136MR25 Automotive Timing Belt For Hyundai Peugeot

Timing belts are crucial components within many mechanical systems, particularly in automotive and industrial machinery. They play an essential role in ensuring seamless operation by synchronizing the rotation of the crankshaft and camshaft. This synchronization is vital as it ensures that engine valves open and close at the correct times during the intake and exhaust strokes, protecting engines from potential damage. For vehicles and machinery operators, understanding the experience-driven benefits, professional maintenance tips, and the authoritative insights into timing belts is key to ensuring long-lasting performance.

In terms of professional advice, timing belt replacement is not a task for the untrained. Proper installation requires precise alignment of components to avoid engine malfunction. A certified technician with specialized training can ensure the belt is correctly tensioned and aligned, taking into consideration the specific torque settings required by different manufacturers. They also have the authority to recommend quality replacement parts that match or exceed original equipment specifications, thereby enhancing the reliability and longevity of the machinery. Trustworthiness in information about timing belts lies in sourcing parts and maintenance from reputable dealers and suppliers who can guarantee product authenticity. Many belts sold online or through non-certified dealers may not meet the rigorous standards set by original manufacturers, posing risks of failure at critical times. It is prudent for consumers to seek parts from certified distributors, where the history of quality and performance is well-documented, ensuring peace of mind for users who rely heavily on their machinery for daily operations. In conclusion, timing belts are more than just simple mechanical components; they are intricate parts that require attention to detail, quality control, and expert handling. For those responsible for automotive or industrial equipment maintenance, appreciating the life cycle, materials, and specialized installation processes of timing belts not only enhances mechanical reliability but also secures a safe and efficient operational environment. Trusting seasoned professionals and certified dealers with this responsibility is a testament to a commitment to excellence and a strategic approach to machinery management. By prioritizing these standards, users can mitigate risks and optimize performance, ensuring that timing belts serve their intended purpose with maximum efficiency and minimum disruption.

In terms of professional advice, timing belt replacement is not a task for the untrained. Proper installation requires precise alignment of components to avoid engine malfunction. A certified technician with specialized training can ensure the belt is correctly tensioned and aligned, taking into consideration the specific torque settings required by different manufacturers. They also have the authority to recommend quality replacement parts that match or exceed original equipment specifications, thereby enhancing the reliability and longevity of the machinery. Trustworthiness in information about timing belts lies in sourcing parts and maintenance from reputable dealers and suppliers who can guarantee product authenticity. Many belts sold online or through non-certified dealers may not meet the rigorous standards set by original manufacturers, posing risks of failure at critical times. It is prudent for consumers to seek parts from certified distributors, where the history of quality and performance is well-documented, ensuring peace of mind for users who rely heavily on their machinery for daily operations. In conclusion, timing belts are more than just simple mechanical components; they are intricate parts that require attention to detail, quality control, and expert handling. For those responsible for automotive or industrial equipment maintenance, appreciating the life cycle, materials, and specialized installation processes of timing belts not only enhances mechanical reliability but also secures a safe and efficient operational environment. Trusting seasoned professionals and certified dealers with this responsibility is a testament to a commitment to excellence and a strategic approach to machinery management. By prioritizing these standards, users can mitigate risks and optimize performance, ensuring that timing belts serve their intended purpose with maximum efficiency and minimum disruption.

Share:

Latest news

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025