- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

dec . 29, 2024 06:04 Back to list

fan belt 6pk

Understanding the Importance of the Fan Belt 6PK

In the realm of automotive maintenance, certain components often go unnoticed until they develop issues that can lead to significant problems. Among these components, the fan belt—specifically the 6PK variant—holds great importance. Often referred to as the serpentine belt, this rubber component is integral to the proper functioning of various systems in an automobile, including the engine cooling system, the power steering pump, and the alternator. In this article, we will explore the significance of the fan belt 6PK, its role in vehicle performance, and how to properly maintain it.

What is a Fan Belt 6PK?

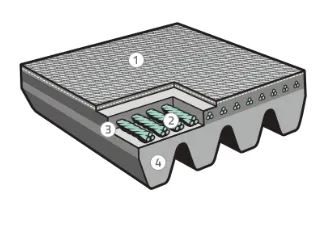

The designation 6PK refers to the number of ribs on the belt. A fan belt with this designation means that it has six longitudinal ribs that provide traction between the belt and the pulleys it wraps around. This specific design enhances the belt's grip and ensures a reliable transfer of power from the engine to the various attached accessories. The 6PK belt is commonly used in a variety of vehicles, making it a popular choice for mechanics and car enthusiasts alike.

Functions of the Fan Belt

The primary function of the fan belt is to transfer the rotational energy produced by the engine to various accessories. These include

1. Alternator The fan belt drives the alternator, which converts mechanical energy into electrical energy, recharging the car battery and powering electrical systems. 2. Water Pump In many designs, the fan belt also operates the water pump, which circulates coolant through the engine, helping to maintain optimal operating temperatures.

3. Power Steering Pump The fan belt can also drive the power steering pump, making it easier to steer the vehicle by providing hydraulic assistance.

fan belt 6pk

Why Maintenance Matters

Like any other mechanical component, the fan belt 6PK is subject to wear and tear over time. Factors such as heat, friction, and environmental exposure can cause the rubber to degrade, leading to cracking, fraying, or even complete failure. Regular maintenance is crucial to ensure the longevity and effectiveness of the fan belt. Here are a few key maintenance tips

1. Visual Inspection Regularly check the belt for signs of wear, such as cracks or frayed edges. Look for any shiny spots that indicate slippage.

2. Tension Check The tension of the fan belt is vital for its performance. If it is too loose, it may slip and fail to drive the attached components adequately. Conversely, if it is too tight, it can cause premature wear to both the belt and the pulleys.

3. Replacement Most manufacturers recommend replacing the serpentine belt every 60,000 to 100,000 miles, but individual conditions may necessitate more frequent changes. Always refer to the vehicle’s service manual for specific guidelines.

4. Professional Help If you're not comfortable conducting these inspections and replacements yourself, it is advisable to seek the expertise of a qualified mechanic. They can ensure that both the belt and the associated components are functioning as they should.

Conclusion

The fan belt 6PK may seem like a minor component, but its role in the vehicle’s operation is essential. By understanding its functions and performing regular maintenance, car owners can prevent costly repairs and ensure that their vehicle runs smoothly and efficiently. Whether you're a seasoned car enthusiast or a casual driver, being mindful of your vehicle's serpentine belt will go a long way in maintaining performance and reliability on the road.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025