- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Dez . 14, 2024 12:28 Back to list

Understanding the Mechanics and Applications of Flat Transmission Belts in Modern Machinery

Understanding Flat Transmission Belts Essential Components of Mechanical Systems

Flat transmission belts have long been a fundamental component in various mechanical systems, playing a crucial role in the transfer of power between different machinery. These belts are characterized by their flat surface, which allows them to effectively transmit motion and force from one pulley to another. This article delves into the design, operation, benefits, applications, and maintenance of flat transmission belts, providing a comprehensive overview of their significance in mechanical engineering.

Design and Construction

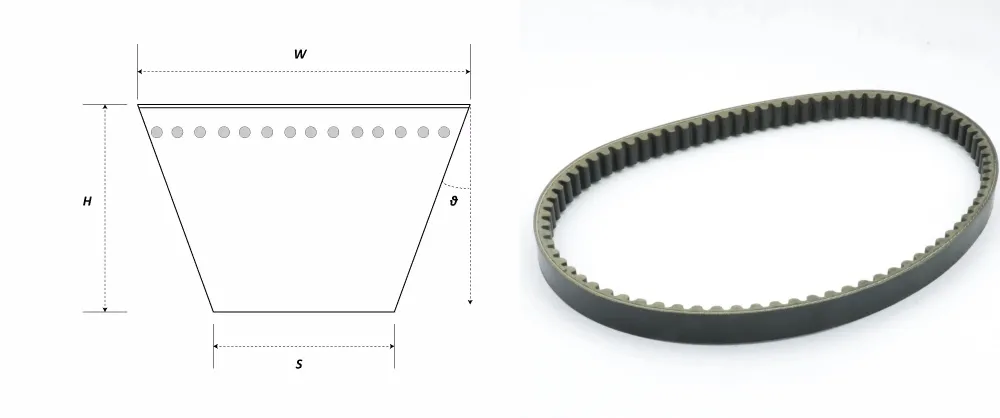

Flat transmission belts are primarily made from materials such as rubber, leather, or synthetic composites. Their flat shape distinguishes them from rounded V-belts, granting them unique properties and advantages. A typical flat belt consists of a flexible piece of material that can be manufactured in various widths and thicknesses, allowing it to cater to specific applications.

The design of flat belts involves considerations such as friction between the belt and pulleys, belt tension, and alignment. The friction generated between the belt and the pulleys is critical for effective power transmission; therefore, the surfaces are often treated or patterned to enhance grip. Additionally, proper tension must be maintained to prevent slippage and ensure efficient operation.

Operation Mechanism

The operation of flat transmission belts is based on the concept of force transmission via friction. When one of the pulleys is driven by a motor or other power source, it rotates, and the flat belt, which wraps around it, is pulled along, thereby rotating the second pulley. The effectiveness of this system largely depends on maintaining the right amount of tension in the belt, as excessive tension can lead to premature wear, while insufficient tension can cause slippage or loss of power transfer.

Advantages of Flat Transmission Belts

1. Efficiency Flat belts can transmit power efficiently over long distances and angles. This capability makes them suitable for applications where machinery is spread out over large areas.

2. Low Maintenance Unlike other types of belts, flat transmission belts tend to require less maintenance. Their simple design often leads to decreased wear and tear, helping to extend their operational lifespan.

3. Versatility These belts can be used in a variety of industries, including manufacturing, agriculture, and transportation. They are effective for both light and heavy-duty applications, making them adaptable to changing operational demands.

4. Cost-Effectiveness Flat belts are generally more affordable compared to other power transmission methods, such as chains or gears, especially when considering installation and maintenance costs.

flat transmission belt

Applications

Flat transmission belts are ubiquitous across many industries. They are commonly used in textile machinery, conveyor systems, agricultural equipment, and wood processing machines. In manufacturing settings, they facilitate the movement of materials between different stages of production, significantly enhancing operational efficiency.

In the automotive industry, flat belts have also found applications, particularly in older vehicle models for operating alternators, air conditioning units, and other auxiliary components. Understanding their utility, many engineers and designers continue to explore innovative ways to integrate flat belts into modern machinery.

Maintenance and Care

To ensure optimal performance and longevity of flat transmission belts, regular maintenance is essential. Key aspects of maintenance include

- Inspection for Wear and Tear Regularly checking the belt for signs of damage, such as cracks or fraying, can help in early detection of potential failures.

- Tension Adjustment Monitoring and adjusting the tension of the belt is crucial to prevent slippage and ensure efficient operation.

- Cleaning Keeping the belts and pulleys clean from debris and contaminants will enhance the lifespan of the belt and maintain its frictional properties.

- Replacement Knowing when to replace a belt is vital. Signs such as excessive wear, noise, or slippage indicate that a replacement may be necessary to maintain optimal performance.

Conclusion

In summary, flat transmission belts are vital components of many mechanical systems, providing efficient power transmission across various applications. Their design, operation principles, and maintenance requirements make them indispensable in the engineering and manufacturing sectors. As technology advances, understanding the role of flat belts and optimizing their use can lead to safer, more effective, and cost-efficient mechanical systems. Whether in traditional manufacturing or innovative new products, flat transmission belts will continue to play a crucial role in the world of machinery.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025