- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Awst . 01, 2024 02:39 Back to list

Exploring the Benefits and Innovations of Silent Synchronization Belts for Modern Machinery Performance

Understanding Silent Sync Belts The Revolution in Power Transmission

In recent years, the manufacturing and automotive industries have undergone significant transformation with the introduction of advanced technology in power transmission systems. Among the innovations, the silent sync belt has emerged as a noteworthy solution, garnering attention for its efficiency and reliability. This article explores the concept of silent sync belts, their functionality, applications, and the benefits they offer over traditional belt systems.

What is a Silent Sync Belt?

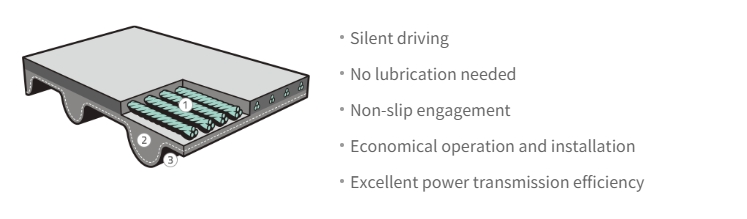

A silent sync belt, often referred to as a synchronous belt, is a high-performance belt designed for power transmission between rotating shafts. Unlike traditional belts, which rely solely on friction to transmit power, silent sync belts operate on a tooth engagement mechanism. This means that the teeth on the belt fit into corresponding grooves on the pulleys, ensuring a positive connection that minimizes slippage. The ‘silent’ aspect refers to the reduced noise and vibrations produced during operation, making it an ideal choice for environments where sound levels must be kept low.

How Do Silent Sync Belts Work?

The silent sync belt's operation is based on the principle of synchronous drive, where the belt's teeth mesh precisely with the teeth of the pulleys. This arrangement provides several advantages

1. Mechanical Efficiency The synchronous nature of the drive system eliminates the slippage that often occurs with traditional belts. As a result, silent sync belts offer improved efficiency and power transfer, making them suitable for high-performance applications.

2. Durability Made from high-quality materials like polyurethane and reinforced with carbon fiber or steel cords, silent sync belts are designed to withstand heavy loads and challenging conditions, leading to a longer service life.

3. Noise Reduction The engineering behind silent sync belts significantly reduces operational noise. This feature is especially beneficial in settings such as office environments, residential areas, and other noise-sensitive locations.

silentsync belt

4. Low Maintenance Synchronous belts require less maintenance than traditional belts. Their design minimizes the need for adjustments and replacements, contributing to lower overall operational costs for industries using them.

Applications of Silent Sync Belts

Silent sync belts find applications across various industries, including

- Automotive Used in timing systems, these belts help synchronize engine components, ensuring that the valves open and close at the right intervals. - Robotics In robotic systems, silent sync belts provide precise motion control, allowing for accurate positioning and repeatable movements.

- Conveyor Systems Many conveyor systems employ silent sync belts to manage the transfer of goods efficiently and quietly, particularly in food processing and packaging industries.

- Textile Machinery Due to their low noise levels, these belts are favored in textile manufacturing, where quiet operation is essential.

The Future of Silent Sync Belts

As technology continues to evolve, the silent sync belt is poised for further advancements. Innovations in materials science and manufacturing processes will likely enhance the performance characteristics of these belts, allowing for increased load capacities and greater operating temperatures. Moreover, the growing emphasis on sustainability may drive the development of eco-friendly synchronous belts, reinforcing the industry's shift toward greener alternatives.

In conclusion, silent sync belts represent a significant shift in power transmission technology. Their unique design provides numerous advantages, including mechanical efficiency, durability, and noise reduction. As industries seek to improve performance and reduce operational noise, the silent sync belt is likely to play an increasingly vital role in the future of manufacturing and automation.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025