- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Ion . 11, 2025 11:31 Back to list

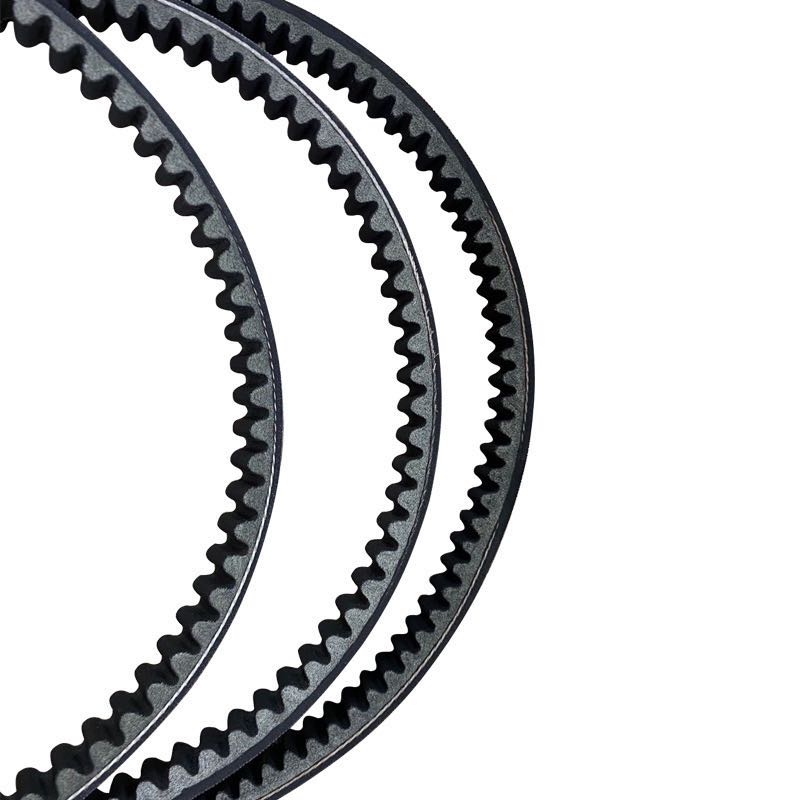

drive belt serpentine belt

Navigating the realm of power transmission technology can often be daunting due to the myriad of options available in the market. Among these, the PK belt stands out as a quintessential component, gaining popularity across various industries due to its versatile application and robust performance characteristics.

In terms of trustworthiness, PK belts are often preferred for their consistent performance and adaptability across various mechanical setups. Numerous OEMs incorporate these belts into their standard design due to their proven track record of reliability and efficiency. Additionally, the adaptability of PK belts allows engineers to customize belt lengths to suit specific system configurations, further enhancing their application across different machinery. When considering product selection for an intended application, one should evaluate the belt’s resistance to environmental stressors such as oil, heat, and ozone exposure. The PK belt excels in these aspects, engineered to withstand adverse conditions that might compromise other types of belts. This makes them an ideal choice for automotive, industrial, and even marine applications where ambient conditions can be unpredictable and harsh. As a steadfast advocate for energy-efficient solutions, I endorse PK belts for their contribution to reduced friction losses and improved energy transmission, aligning with global trends towards greener, more sustainable industrial practices. Utilizing PK belts ultimately results in lower operational costs and a reduced carbon footprint—a win-win for companies and the environment alike. In conclusion, the adoption of the PK belt in multiple domains underscores its importance as a reliable power transmission solution. By addressing common concerns such as operational longevity, maintenance reduction, and energy efficiency, PK belts have carved a niche for themselves in the competitive landscape of transmission technology. Equipped with these insights, stakeholders can make informed decisions about integrating PK belts into their systems, fostering enhanced productivity and operational excellence.

In terms of trustworthiness, PK belts are often preferred for their consistent performance and adaptability across various mechanical setups. Numerous OEMs incorporate these belts into their standard design due to their proven track record of reliability and efficiency. Additionally, the adaptability of PK belts allows engineers to customize belt lengths to suit specific system configurations, further enhancing their application across different machinery. When considering product selection for an intended application, one should evaluate the belt’s resistance to environmental stressors such as oil, heat, and ozone exposure. The PK belt excels in these aspects, engineered to withstand adverse conditions that might compromise other types of belts. This makes them an ideal choice for automotive, industrial, and even marine applications where ambient conditions can be unpredictable and harsh. As a steadfast advocate for energy-efficient solutions, I endorse PK belts for their contribution to reduced friction losses and improved energy transmission, aligning with global trends towards greener, more sustainable industrial practices. Utilizing PK belts ultimately results in lower operational costs and a reduced carbon footprint—a win-win for companies and the environment alike. In conclusion, the adoption of the PK belt in multiple domains underscores its importance as a reliable power transmission solution. By addressing common concerns such as operational longevity, maintenance reduction, and energy efficiency, PK belts have carved a niche for themselves in the competitive landscape of transmission technology. Equipped with these insights, stakeholders can make informed decisions about integrating PK belts into their systems, fostering enhanced productivity and operational excellence.

Share:

Latest news

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025