- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Říj . 16, 2024 15:47 Back to list

v belts for lathes

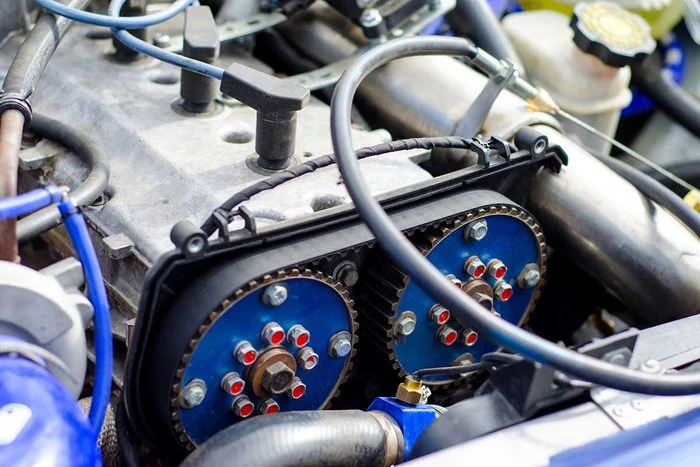

Understanding V-Belts for Lathes A Comprehensive Guide

In the world of machining and metalworking, lathes are essential tools that allow for precision shaping of materials. An integral component of many lathes is the V-belt, which plays a crucial role in transferring power from the motor to the spindle, facilitating smooth and efficient operation. This article delves into the significance of V-belts in lathes, their types, maintenance tips, and how to choose the right one for your machine.

What are V-Belts?

V-belts are a type of power transmission belt characterized by their trapezoidal cross-section. This design allows them to fit snugly in the grooves of pulleys, enhancing friction and improving the transfer of power. Commonly made from rubber or synthetic materials, V-belts are preferred in various applications due to their efficiency and durability.

Importance of V-Belts in Lathes

Lathes require reliable power transmission for optimal performance. The V-belt serves as a vital link between the motor and the lathe's spindle. A well-functioning V-belt ensures that the spindle operates at the correct speed, allowing for precise cuts and consistent work quality. If the V-belt is worn or damaged, it can lead to slippage, overheating, or even complete machine failure.

Types of V-Belts

There are several types of V-belts available in the market, each designed for specific applications

1. Classical V-Belts The most common type, available in various sizes. They are versatile and can be used in many lathe models. 2. Narrow V-Belts These belts are narrower than classical V-belts and can handle higher speeds, making them suitable for machines that require quick operation. 3. Cogged V-Belts Designed with notches or cogs, these belts provide flexibility and better grip, making them ideal for high-torque applications. 4. Joined V-Belts These are multiple single belts joined together, providing the power of a wider belt while being easier to handle and install.

v belts for lathes

Maintenance Tips for V-Belts

To ensure the longevity and performance of V-belts in lathes, regular maintenance is essential

- Inspection Regularly check the V-belts for signs of wear, fraying, or cracking. Early detection of issues can prevent sudden breakdowns. - Tensioning Proper tension is vital. A belt that is too loose will slip, while one that is too tight can cause premature wear on both the belt and the pulleys. - Alignment Ensure that the pulleys are properly aligned. Misalignment can lead to uneven wear and increased chances of failure.

- Cleaning Dirt and debris can accumulate on V-belts and pulleys, reducing efficiency. Regular cleaning can mitigate this issue.

Choosing the Right V-Belt

Selecting the correct V-belt for a lathe involves considering several factors, including the machine's specifications, the required power transmission capacity, operational speed, and the environmental conditions. Always opt for belts from reputable manufacturers and consult the lathe’s owner manual for recommended specifications.

Conclusion

V-belts are vital components in the functioning of lathes, significantly influencing their performance and efficiency. By understanding their importance, types, and maintenance needs, operators can ensure smooth operation and extended lifespan of their equipment. Investing in quality V-belts and maintaining them properly will undoubtedly lead to better productivity and reliability in machining tasks.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025