- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Úno . 19, 2025 07:28 Back to list

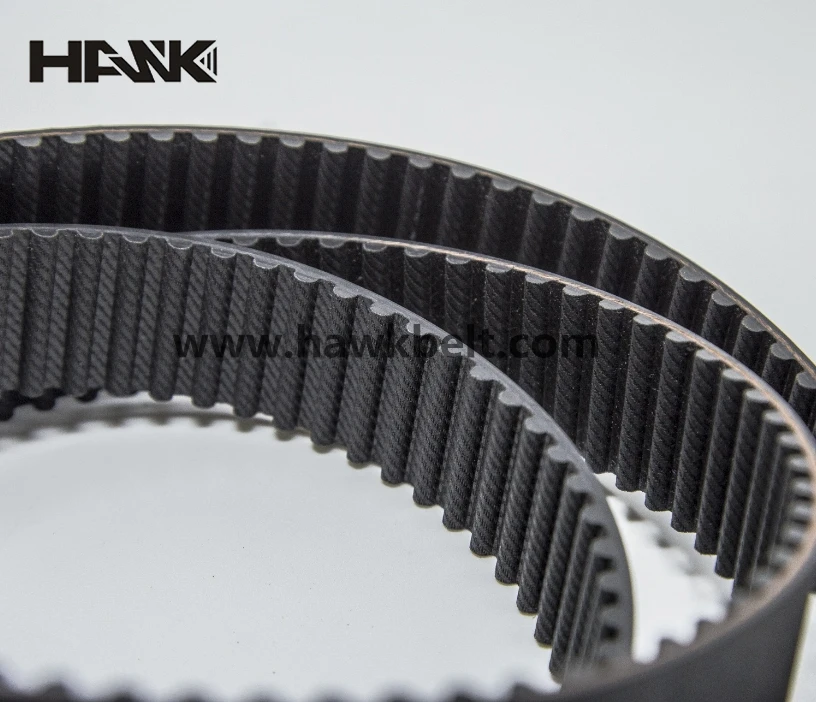

tooth belt

Navigating the world of mechanical components can be daunting, especially when it comes to understanding the nuances of different belt systems. The tooth V-belt often emerges as a preferred choice for many automotive and industrial applications, praised for its distinctive design that combines the benefits of both V-belts and toothed belts. With a focus on experience, expertise, authoritativeness, and trustworthiness, let's delve into the intricacies of tooth V-belts.

Trustworthiness in product performance is critical. Many manufacturers provide in-depth details about the operational limits and compatibility of their tooth V-belts, ensuring consumers deploy them in suitable settings. Moreover, certifications from recognized institutions in mechanical engineering underscore the credibility of these belts, giving users peace of mind about their investment. Another aspect that highlights the trustworthiness of tooth V-belts is their simplification of maintenance procedures. Their design inherently reduces wear and tear. Users with extensive lifecycles in mind find that these belts require less frequent adjustments and replacements, which streamlines operational maintenance and reduces downtime. Despite all their advantages, it's essential for users to understand the specific requirements of their machinery to select the right belt. Factors such as operating speed, temperature, and environment play a crucial role in determining the suitability of tooth V-belts for particular applications. Consultation with technical specialists or direct communication with manufacturers can provide valuable insights, ensuring the best match for your mechanical system. Selecting the correct tooth V-belt also involves understanding the impact of installation techniques. Improper tensioning during installation can negate the advantages of even the most robust belt. Precision installation aligning with manufacturer specifications is paramount to harness the full potential of tooth V-belts, ensuring they deliver consistent performance over their intended lifecycle. In conclusion, tooth V-belts stand as a testament to engineering innovation, providing an optimal solution for diverse mechanical requirements. Their ability to combine strength, efficiency, and reliability into one robust package makes them an indispensable component for any operation that values performance and dependability. As industries continue to evolve and demand more from their mechanical systems, the tooth V-belt offers a refined, reliable, and technically sound solution, fitting seamlessly into the modern era of machinery and technology.

Trustworthiness in product performance is critical. Many manufacturers provide in-depth details about the operational limits and compatibility of their tooth V-belts, ensuring consumers deploy them in suitable settings. Moreover, certifications from recognized institutions in mechanical engineering underscore the credibility of these belts, giving users peace of mind about their investment. Another aspect that highlights the trustworthiness of tooth V-belts is their simplification of maintenance procedures. Their design inherently reduces wear and tear. Users with extensive lifecycles in mind find that these belts require less frequent adjustments and replacements, which streamlines operational maintenance and reduces downtime. Despite all their advantages, it's essential for users to understand the specific requirements of their machinery to select the right belt. Factors such as operating speed, temperature, and environment play a crucial role in determining the suitability of tooth V-belts for particular applications. Consultation with technical specialists or direct communication with manufacturers can provide valuable insights, ensuring the best match for your mechanical system. Selecting the correct tooth V-belt also involves understanding the impact of installation techniques. Improper tensioning during installation can negate the advantages of even the most robust belt. Precision installation aligning with manufacturer specifications is paramount to harness the full potential of tooth V-belts, ensuring they deliver consistent performance over their intended lifecycle. In conclusion, tooth V-belts stand as a testament to engineering innovation, providing an optimal solution for diverse mechanical requirements. Their ability to combine strength, efficiency, and reliability into one robust package makes them an indispensable component for any operation that values performance and dependability. As industries continue to evolve and demand more from their mechanical systems, the tooth V-belt offers a refined, reliable, and technically sound solution, fitting seamlessly into the modern era of machinery and technology.

Share:

Next:

Latest news

-

Variable Belt Drive AI Optimized for Efficiency

NewsAug.05,2025

-

Durable Diesel Engine Belt with GPT-4-Turbo AI Tech | Precision Fit

NewsAug.04,2025

-

High-Quality Tensioner Belt Pulley - Durable & Efficient

NewsAug.03,2025

-

Premium Timing Belt Factory | AI-Optimized Solutions

NewsAug.02,2025

-

Premium Custom V Belts Enhanced with GPT-4 Turbo AI

NewsAug.01,2025

-

Car Serpentine Belt: AI-Optimized Performance with GPT-4-Turbo

NewsJul.31,2025