- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Lis . 20, 2024 01:23 Back to list

metric variable speed belts

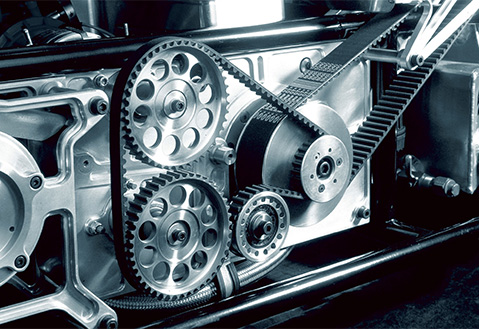

Understanding Metric Variable Speed Belts

Variable speed belts are crucial components in a multitude of mechanical systems, particularly in applications that require precise control over speed and torque. The metric variable speed belt, specifically, has gained traction in industries across the globe due to its efficiency and adaptability. This article explores the characteristics, advantages, and applications of metric variable speed belts.

What are Metric Variable Speed Belts?

Metric variable speed belts are circular loops made from high-strength materials designed to transmit power between pulleys while allowing for adjustable speeds. These belts often feature a trapezoidal cross-section, which facilitates a snug fit in pulley systems, thereby enhancing grip and reducing slippage. The metric designation refers to their dimensions and specifications modeled on the metric system, making them compatible with a range of international machinery standards.

Advantages of Metric Variable Speed Belts

1. Speed Control One of the primary benefits of variable speed belts is their ability to adjust the speed of connected machinery seamlessly. This capability is essential in processes requiring different speeds, such as mixing, grinding, or conveyor operations.

2. Energy Efficiency Variable speed drives (VSDs) paired with metric variable speed belts optimize energy consumption by adjusting motor speeds to match load requirements. This results in significant energy savings over time, promoting a greener manufacturing footprint.

metric variable speed belts

3. Enhanced Performance These belts minimize vibration and wear in mechanical systems, leading to smoother operation and extended equipment lifespan. The precision of speed control also improves the quality and consistency of the final product.

4. Versatility Metric variable speed belts can be used in various applications, from automotive and manufacturing to agricultural machinery. Their adaptability ensures they perform well across different environments and conditions.

Applications of Metric Variable Speed Belts

Metric variable speed belts find applications in various sectors. In the automotive industry, they are pivotal in power transmission systems, allowing for precise adjustments in engine performance. In manufacturing, industries utilize these belts in conveyors and mixers, where speed flexibility is essential for productivity. Additionally, they are also used in HVAC systems, where precise airflow management is crucial.

Conclusion

Metric variable speed belts represent a sophisticated solution for industries seeking efficiency and adaptability in their operations. Their ability to provide precise speed control and enhance energy efficiency makes them invaluable in modern mechanical systems. As technology and industrial needs continue to evolve, the role of these belts is expected to expand, paving the way for innovative applications and improved productivity across various sectors. With their numerous benefits, metric variable speed belts are indeed a cornerstone of modern engineering.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025